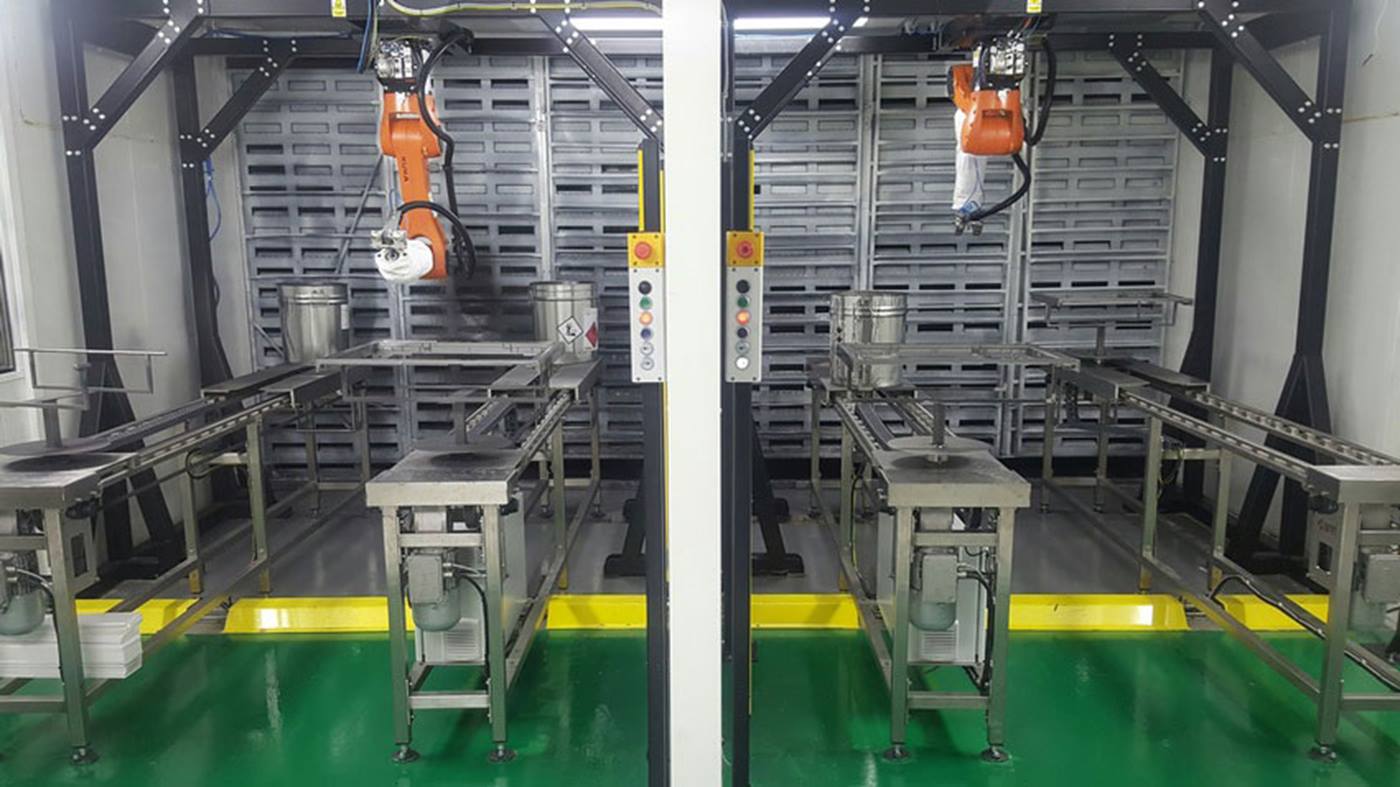

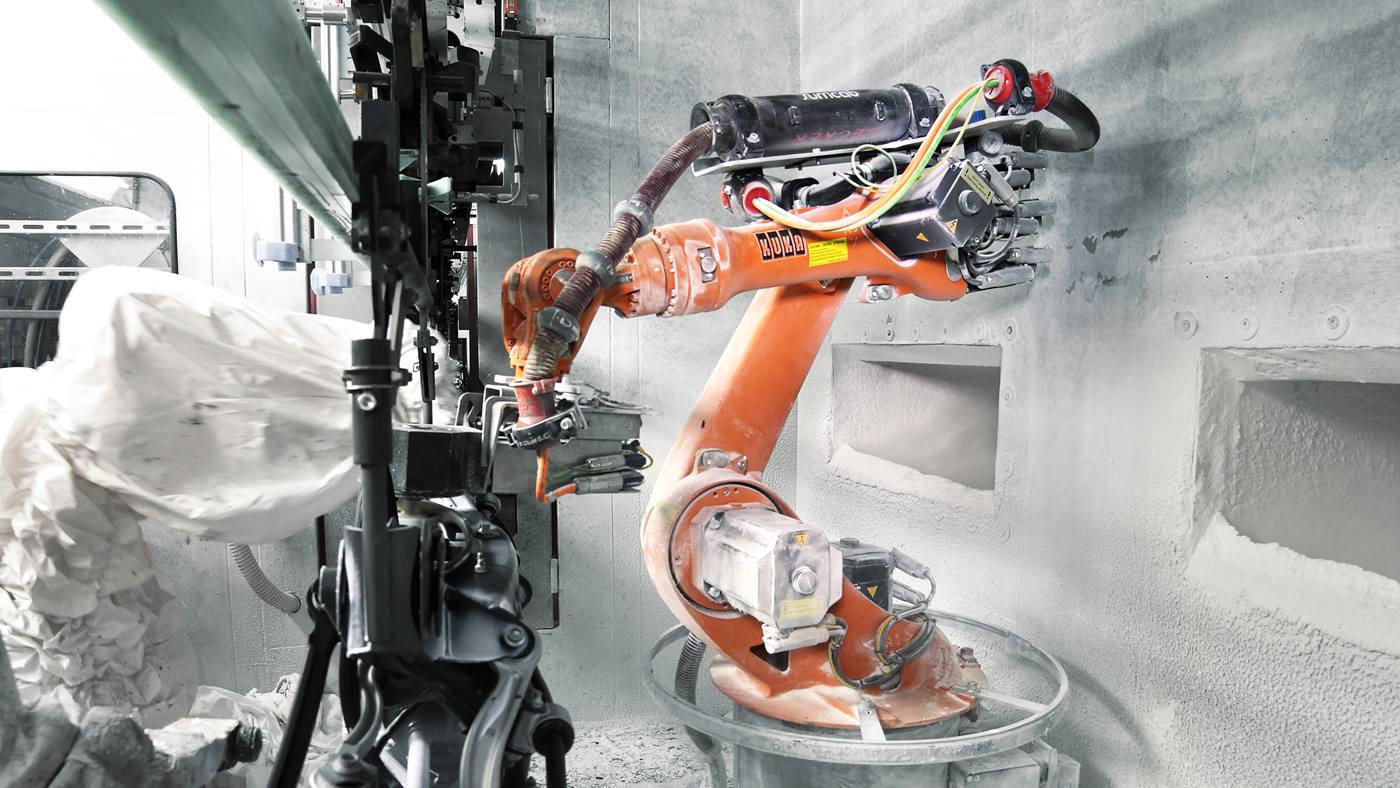

Perfect finish with KUKA painting robots

Safety and efficiency guaranteed

KUKA robots impress with their intelligence, precision and speed and can be used in an extensive range of robotic automation tasks across a wide variety of different industries. The robots are optimized for the painting process for use in water-soluble spray paint applications and for powder applications. Explosions often occur when spraying with flammable aerosols, such as gases and mists; this can seriously impact production. Our painting robots are based on state-of-the-art robotic technology, thus making the robot systems explosion-proof and ATEX compliant, according to 3G/3B. They are continuously purged internally with air to prevent the accumulation of gas. This ensures maximum safety in your facility, avoiding deflagration or accumulation of toxic paint gases.