Ce avantaje aduce pentru companii automatizarea industrială?

Automatizarea producției le oferă companiilor numeroase avantaje prin combinarea roboticii moderne, a software-ului inteligent și a tehnologiilor digitale.

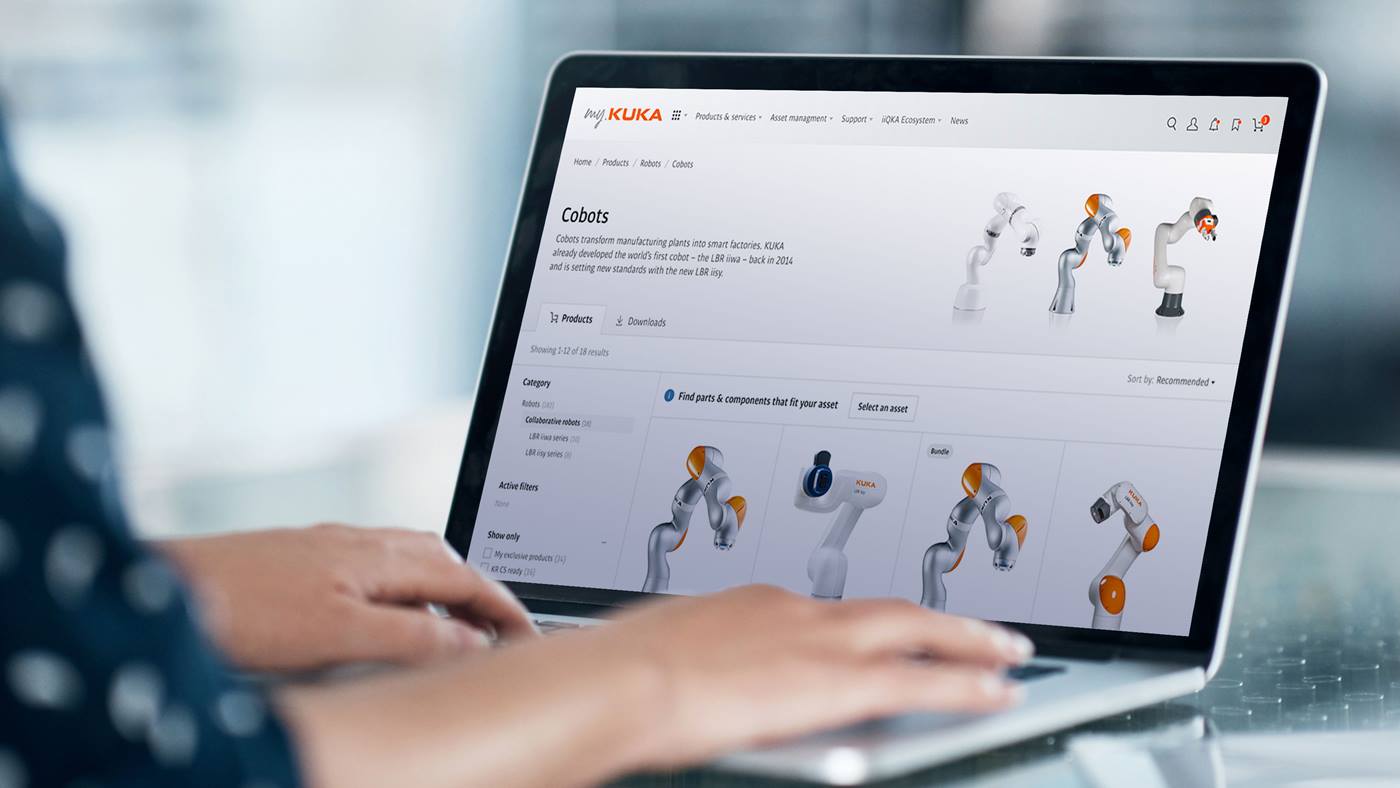

- Robotica permite automatizarea precisă a sarcinilor care sunt greu de implementat cu procese manuale sau utilaje clasice. Gradul ridicat de flexibilitate permite adaptarea rapidă a proceselor de producție la diferite cerințe de piață, variante de produse și loturi de produse.

- Instalațiile de producție funcționează în permanență, cu precizie constantă, ceea ce sporește productivitatea și asigură calitatea.

- Automatizarea reduce în același timp costurile prin optimizarea consumului de resurse și prin reducerea ratelor de eroare.

- Roboții preiau activitățile periculoase sau monotone, sporind astfel siguranța la locul de muncă și reducând riscul de accident.

Concluzie: Automatizarea industrială îmbunătățește nu numai eficiența, ci și viabilitatea și poziția concurențială ale companiilor din toate sectoarele de activitate. Nu numai marile companii au parte de beneficii: Întreprinderile mici și mijlocii sunt, de asemenea, din ce în ce mai puternice – acestea dobândesc un nou potențial, își sporesc agilitatea și reacționează mai rapid la schimbările de pe piață.