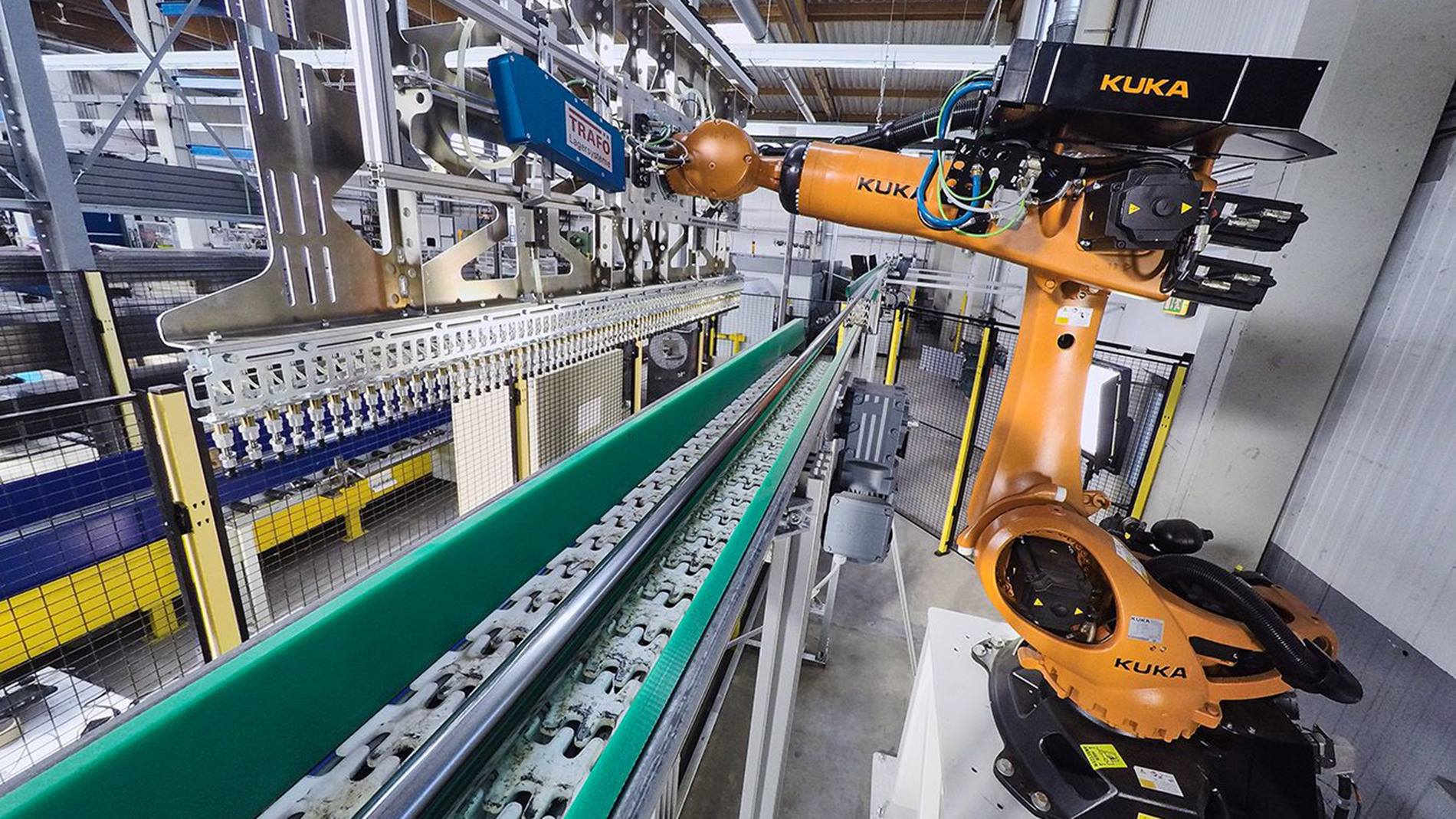

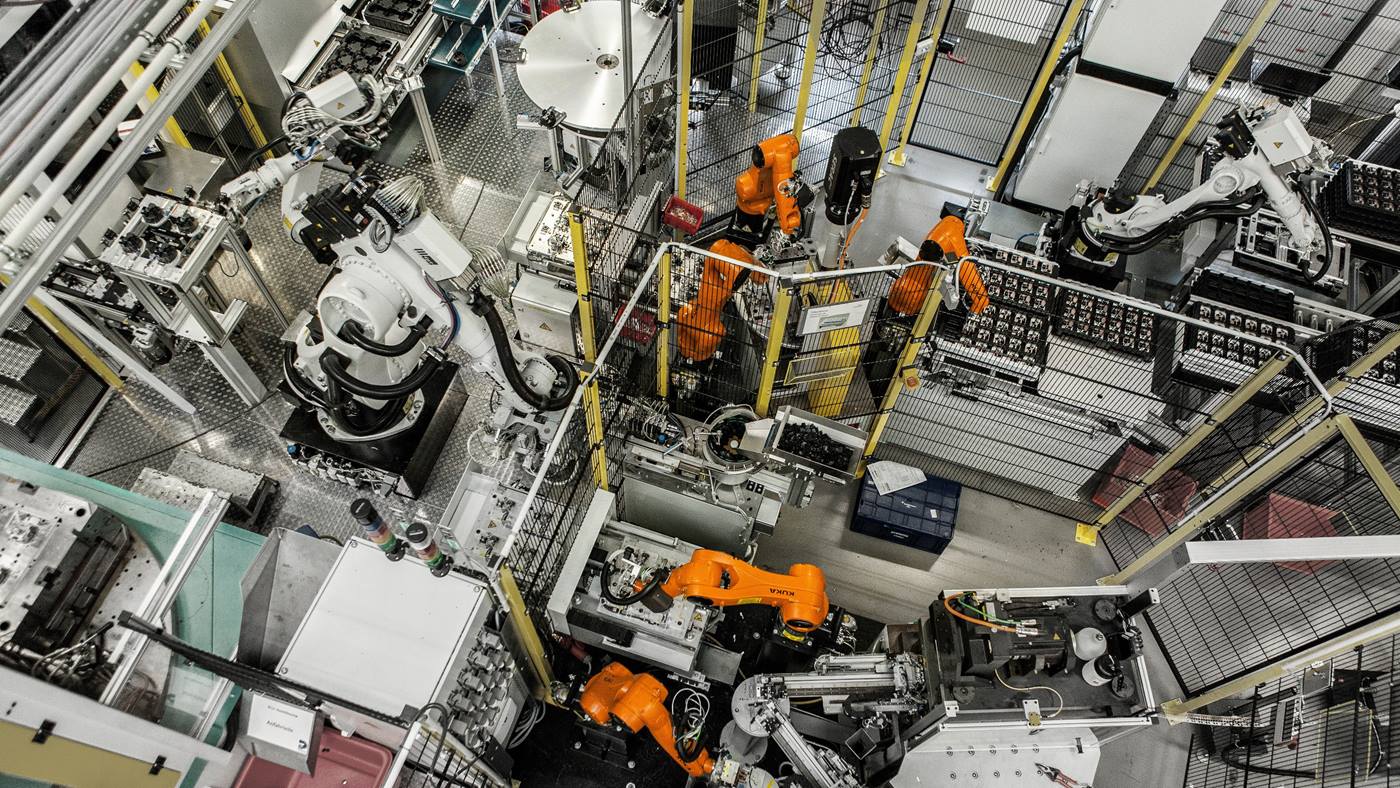

Automated loading of the tube laser is perfectly tailored to the specific circumstances

“The special thing about the pick-and-place robot is that it supplies the laser with individual tubes,” says Ulrich Neckermann, Sales Manager for DACH at Trafö. “Manual loading is no longer necessary.” Trafö has developed special software for the system. This enables all components involved to communicate with one another. Digital production plans specify the types of tube with which the laser is to be loaded fully automatically. The material is ordered from the long material storage system via tablet. The storage system supplies the ordered tubes on system cassettes to the robotic cell via a conveyor system that leads from the warehouse to the robot and from there to the laser. The cassettes are open at the top and usually contain several different tube types. In order to ensure that objects are recognized, the robot is equipped with a 3D detection system.