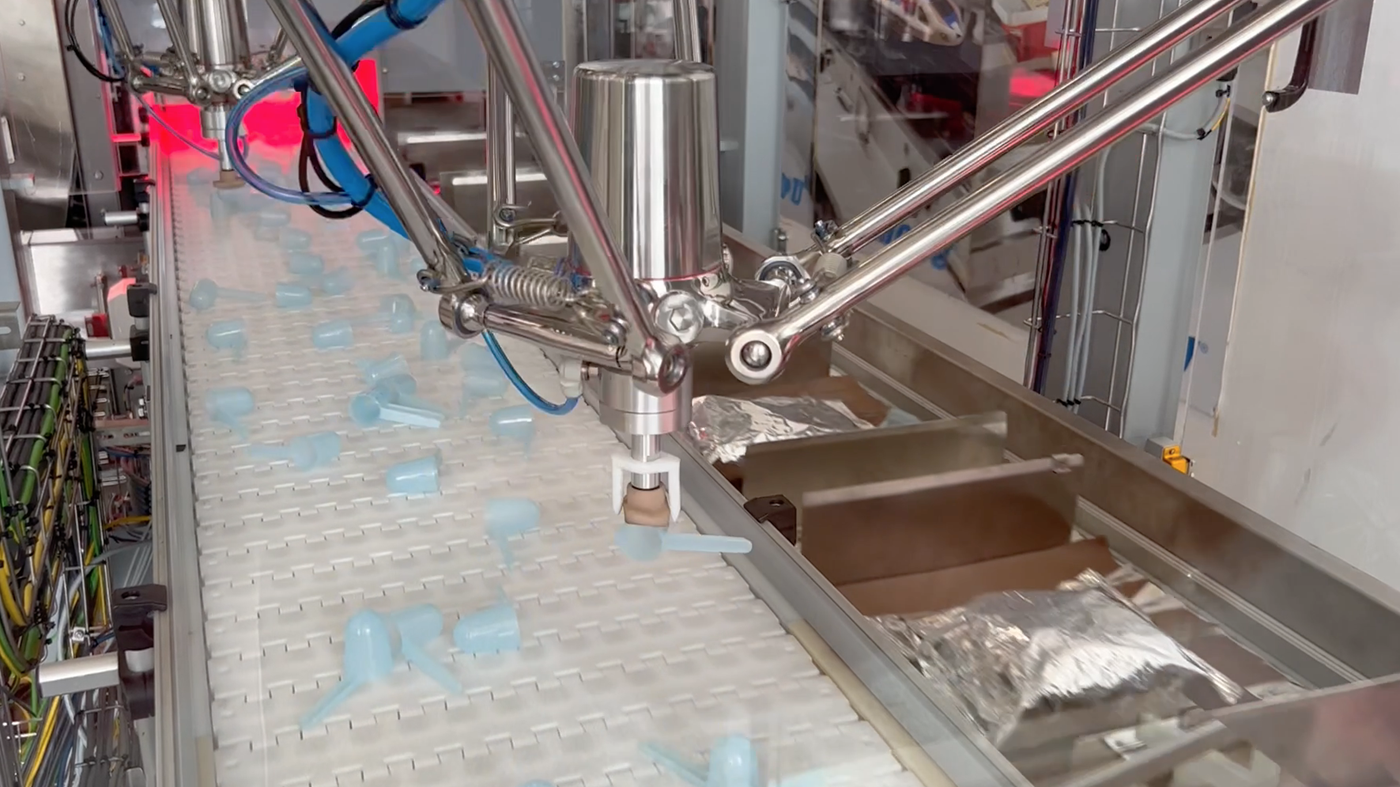

Up to 80 spoons per minute

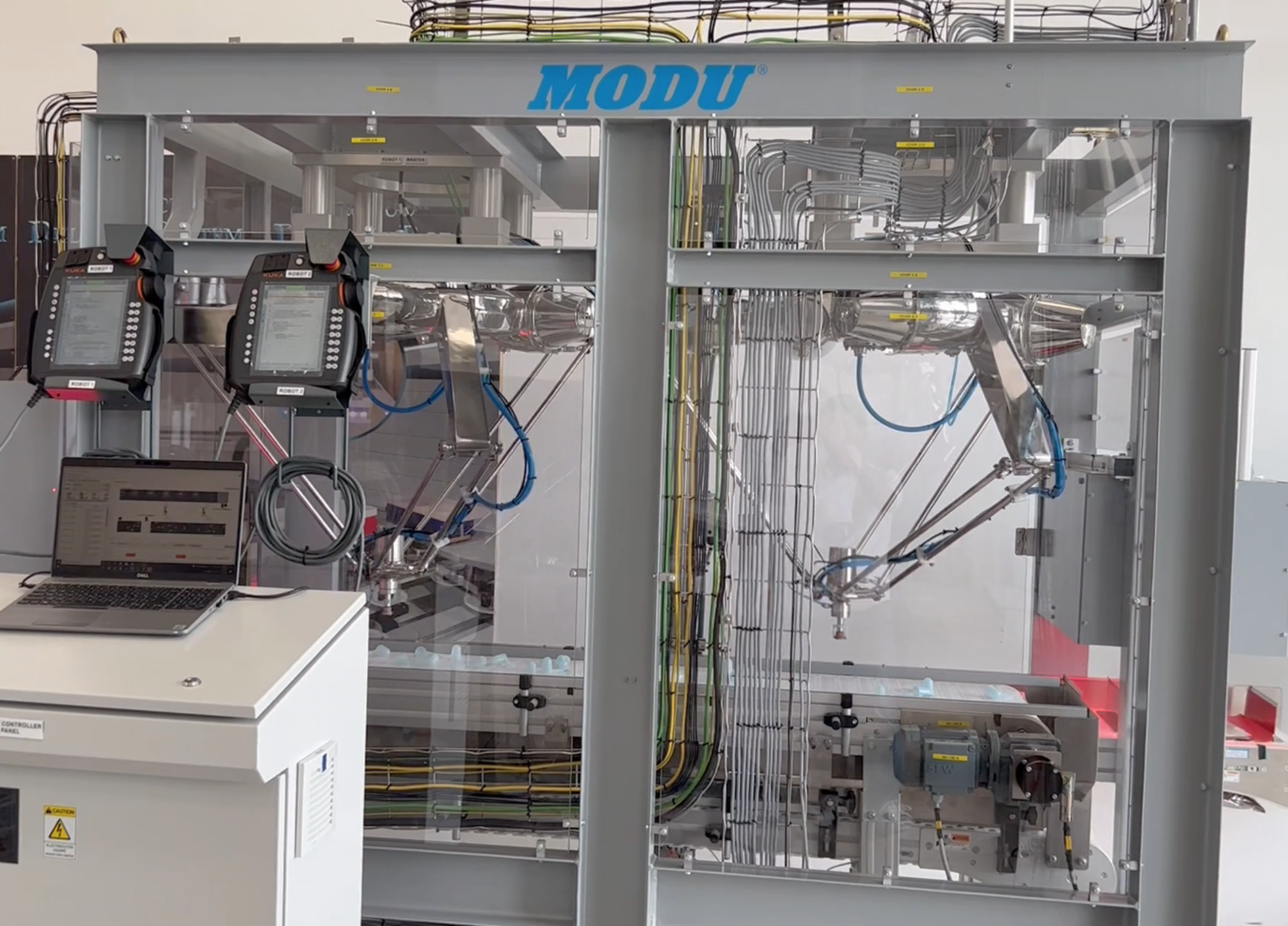

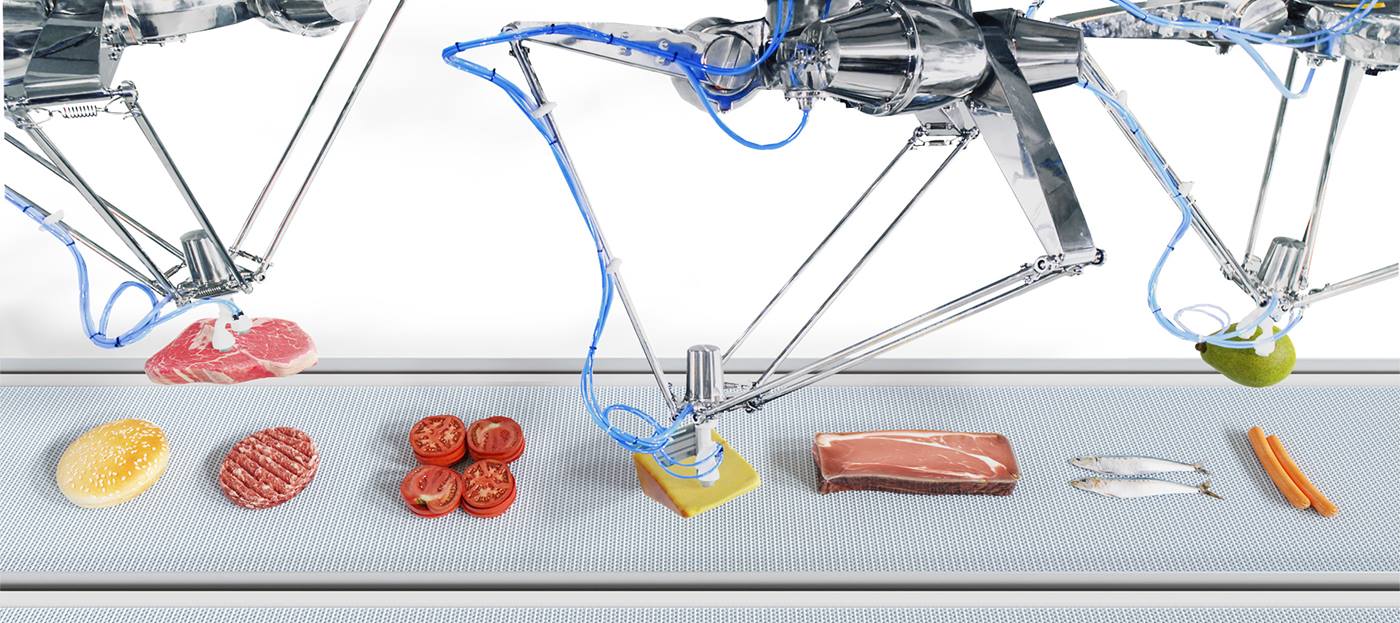

“The customer has great confidence in the automation solution that KUKA and MODU System have developed,” Singh explained. “We ourselves are very impressed with the stainless steel design of the KR DELTA and believe that the application is ideally suited to the food industry, which places great emphasis on hygiene. The system is very easy to operate, looks good, and the stainless steel robot design convinced our food-industry customer. I am very satisfied with the automation.”