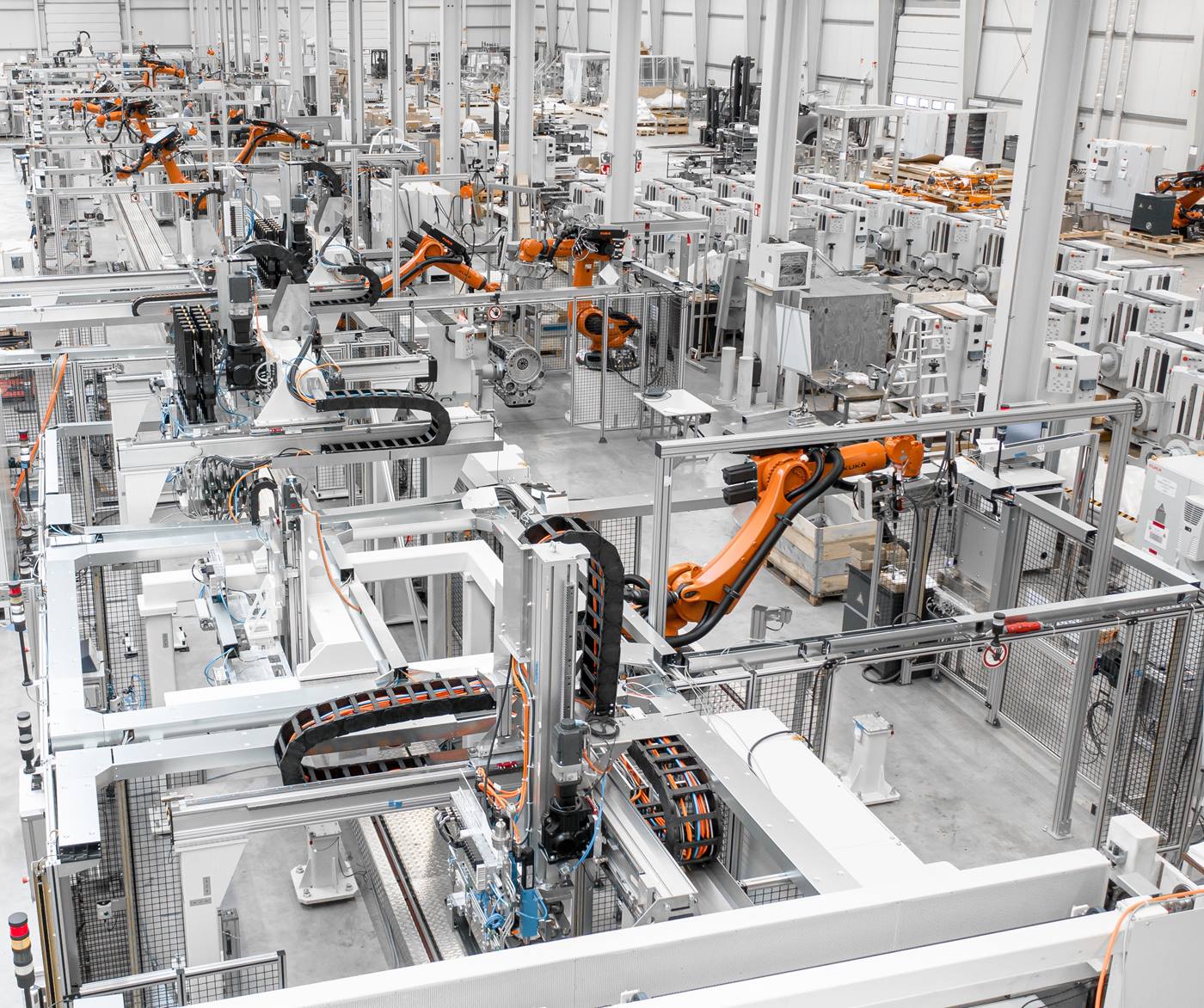

Digitally planned, automatically manufactured: 2D panels for individual construction projects

The production of the 2D panels is scheduled to start in mid of 2026. With this new technology, it will be possible to respond flexibly and quickly to different customer requirements. The highly automated manufacturing process ensures not only consistent quality but also reliable scheduling of orders, offering a major advantage for construction companies and end customers. By combining digital planning with automated production, 2D panels are created that are perfectly tailored to the requirements of each project. This makes homebuilding efficient, sustainable, and future-proof.

“This is a milestone for Adelaide as a manufacturing site and will strengthen the competitiveness of the Australian construction industry,” adds Timo Heil, CEO of KUKA Systems EMEA.