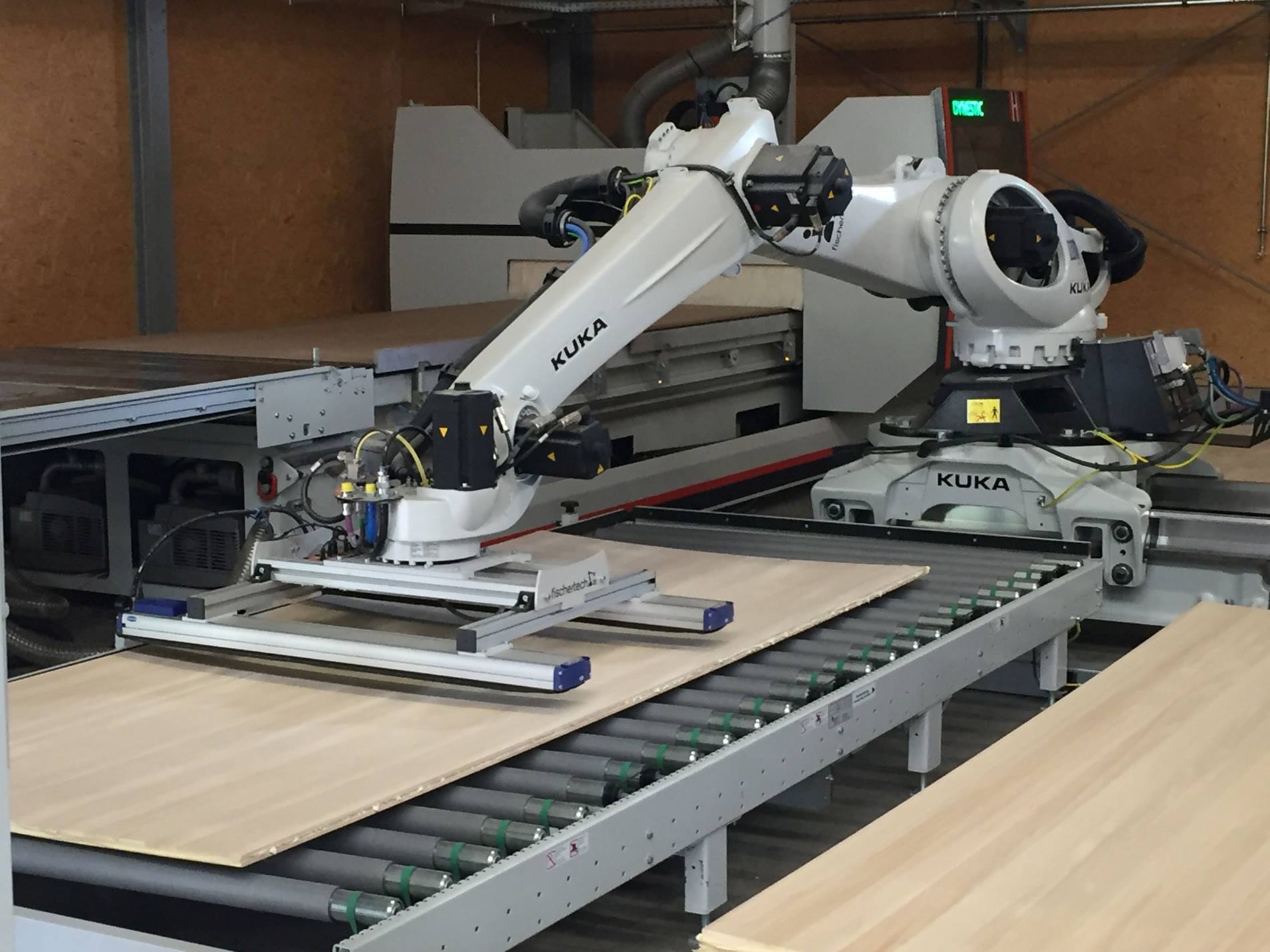

Tending of the wood processing machine by a KUKA robot makes for a successful solution

Since the woodworking machines are part of a new system, it was possible to plan a structured tending process with the KUKA robot from the outset and to implement it without difficulties. The KR QUANTEC has been in operation at Sägewerk Echtle since December 2017 and has fully met the expectations for the automation solution. Planning is already in progress for the next robotic cell.