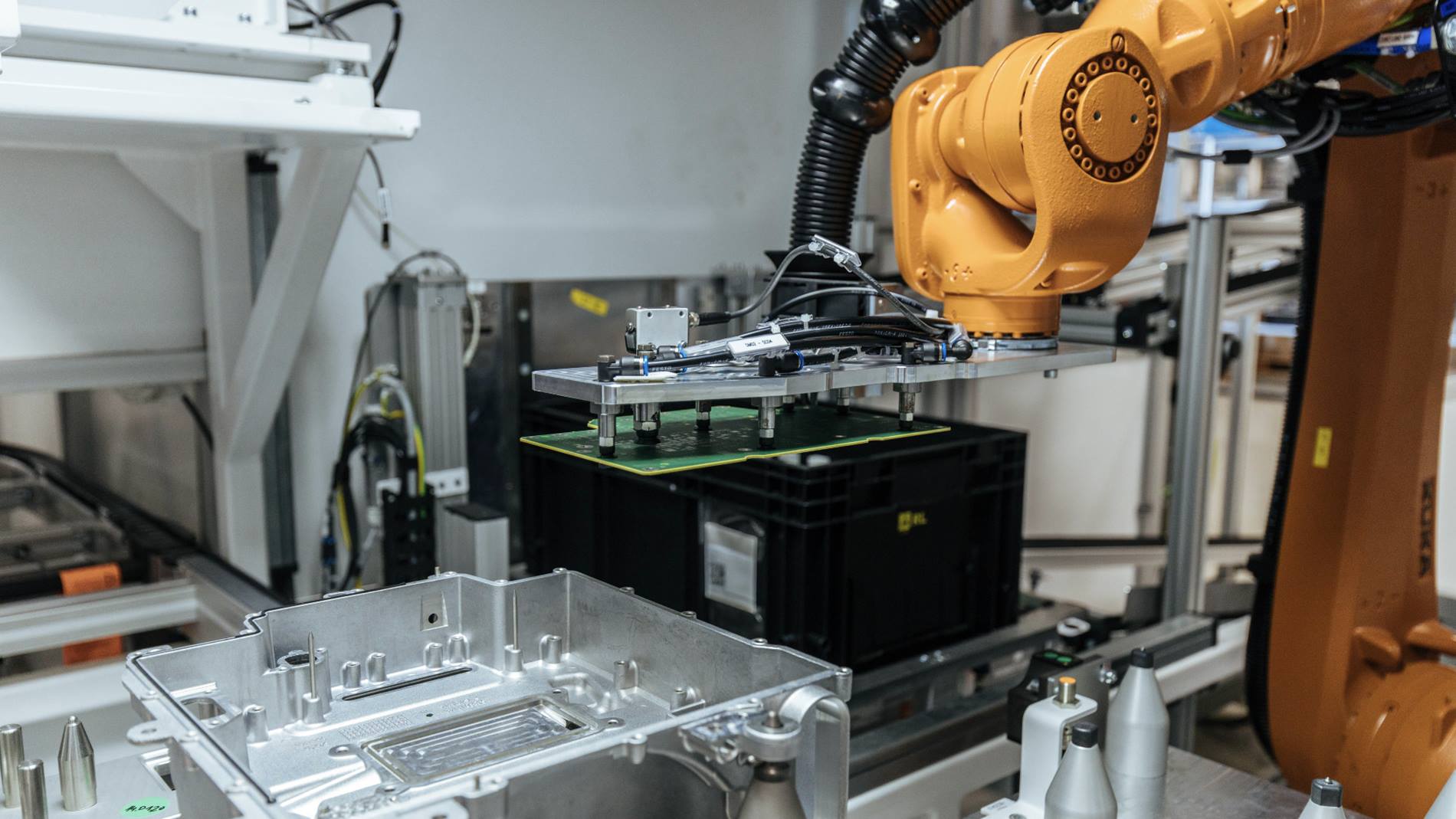

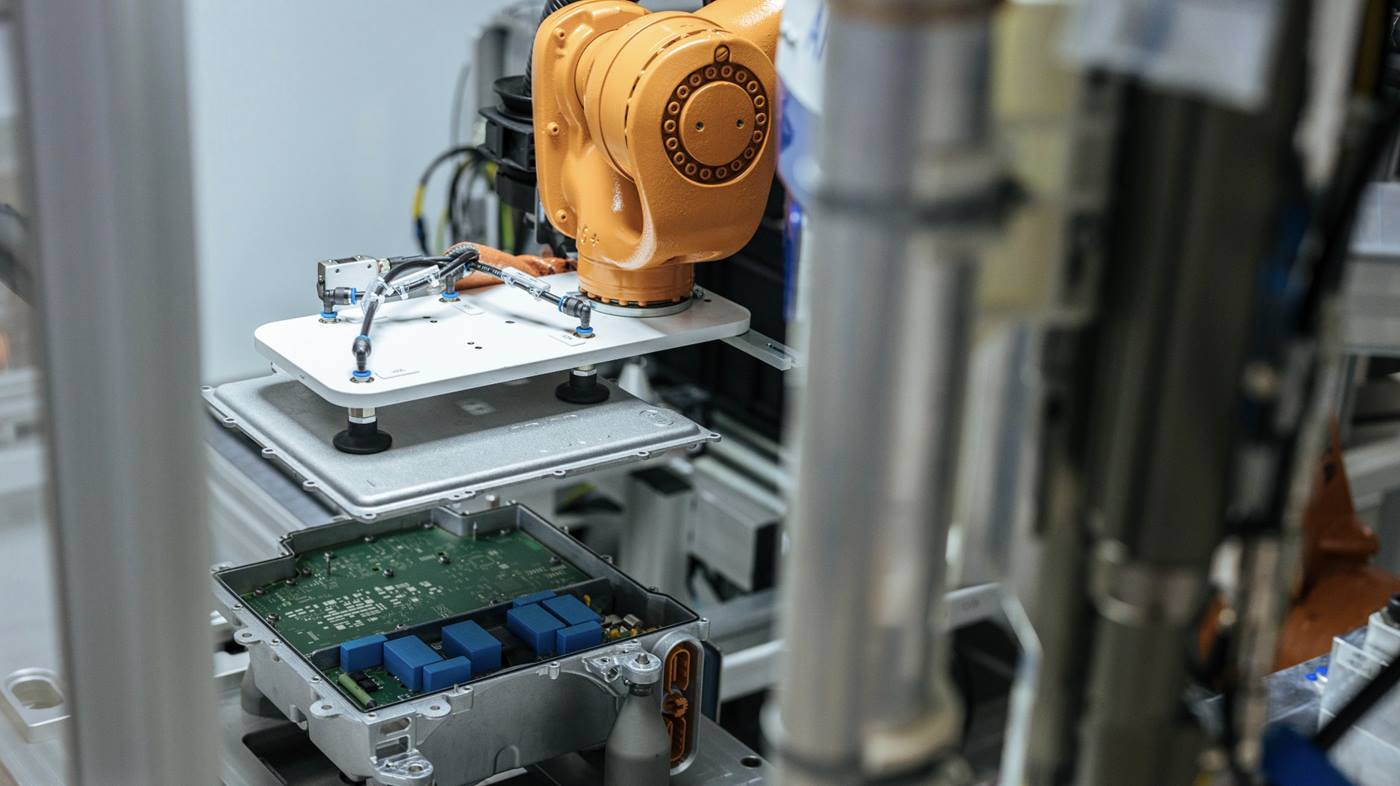

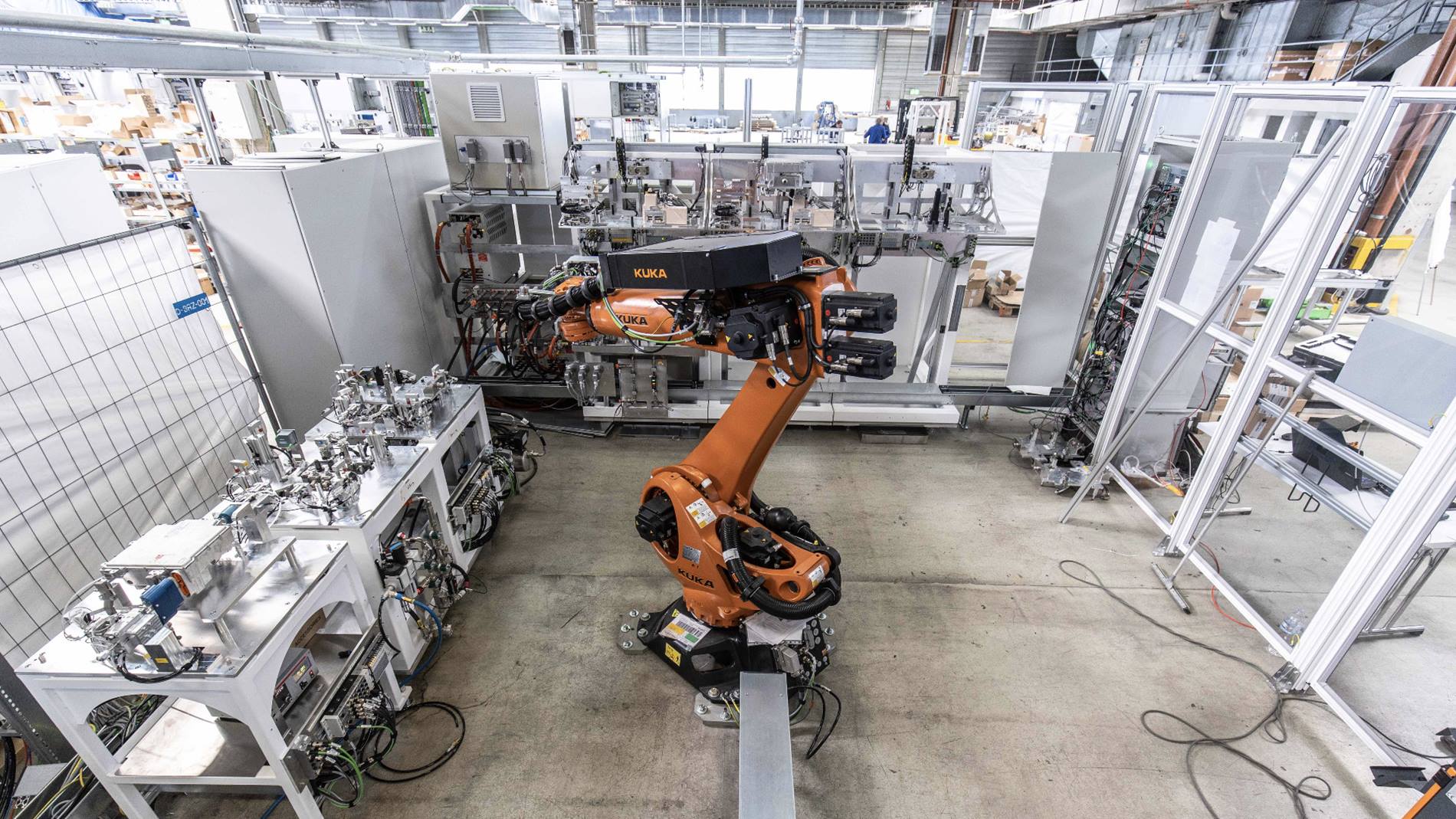

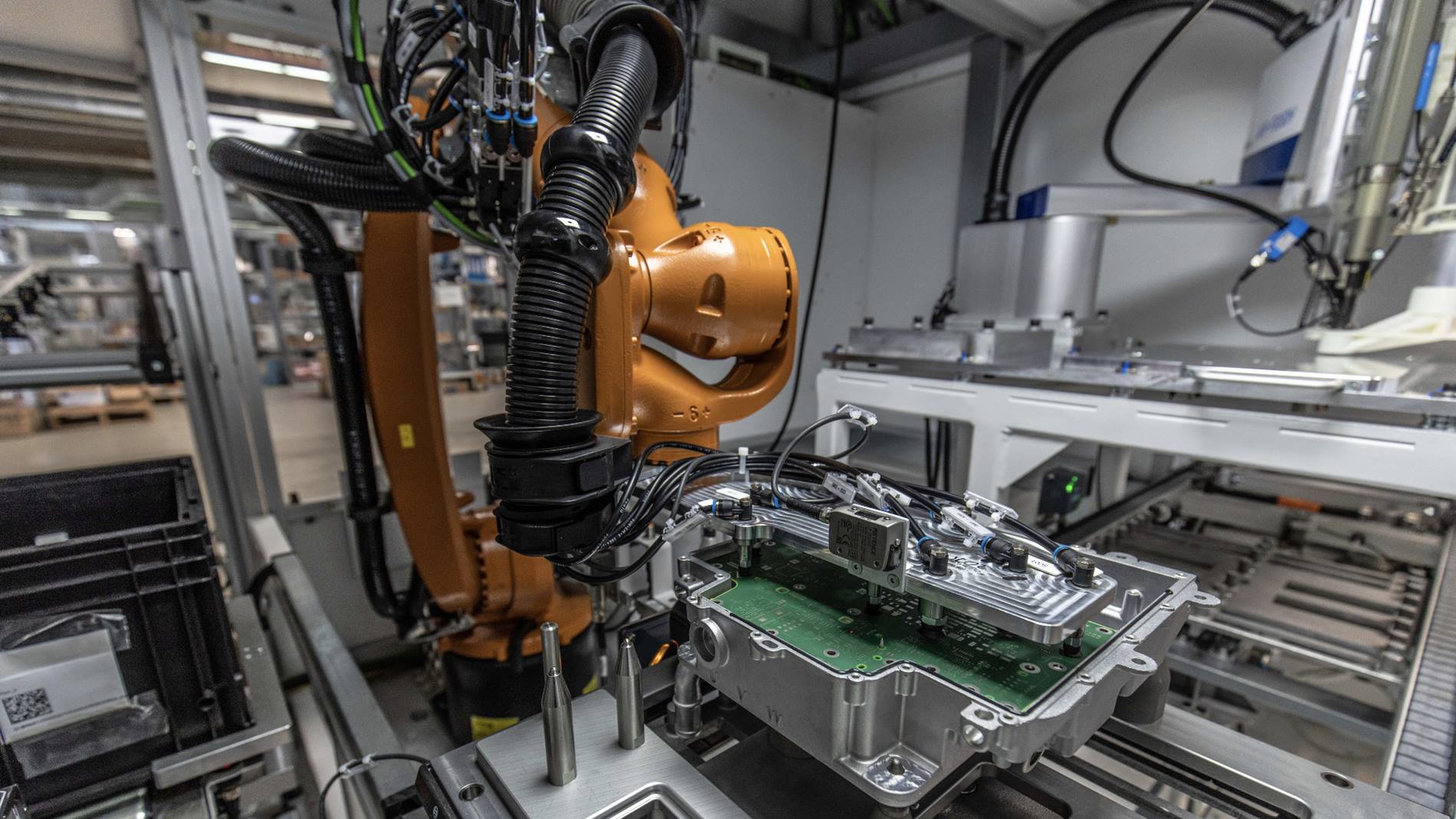

Automated production of the electromobility control element

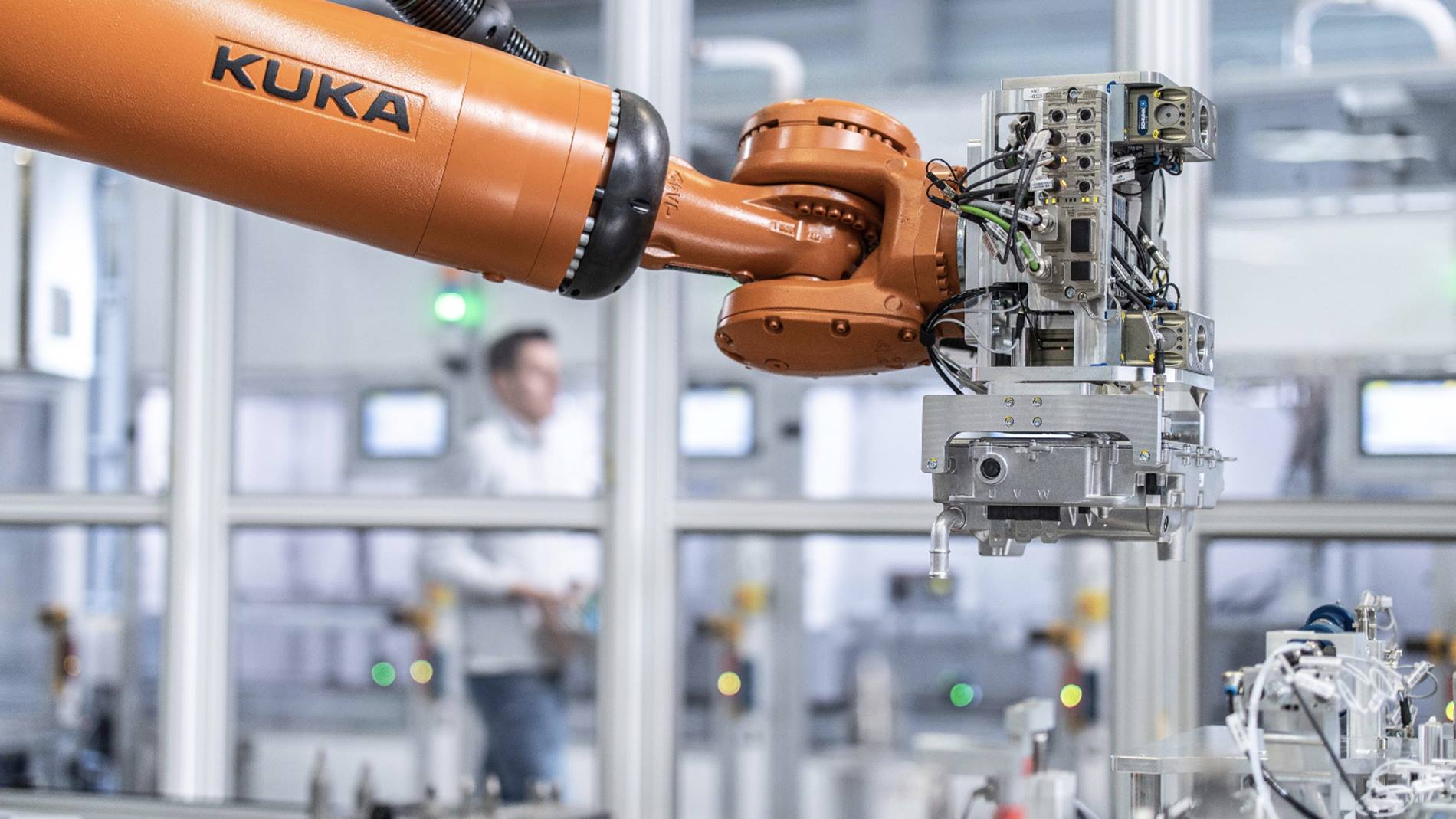

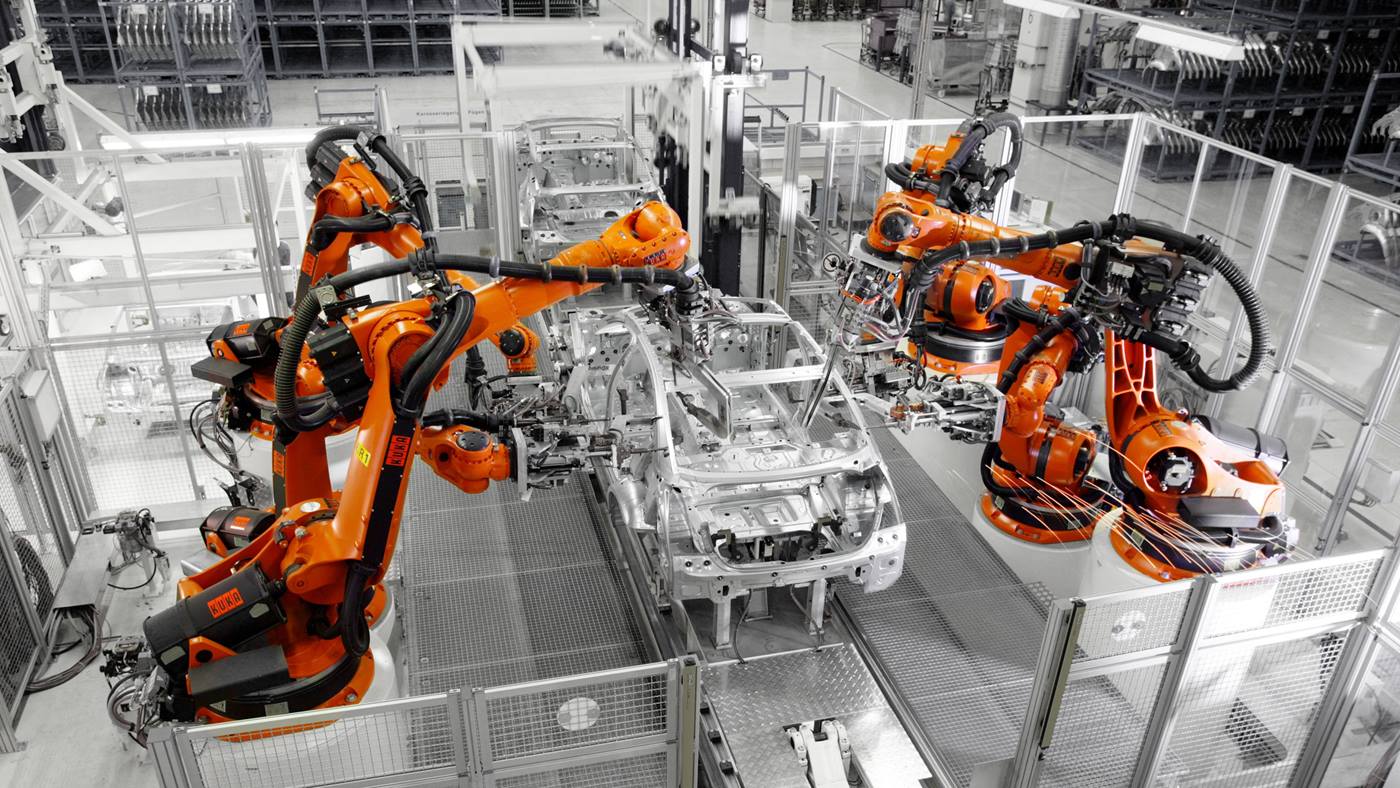

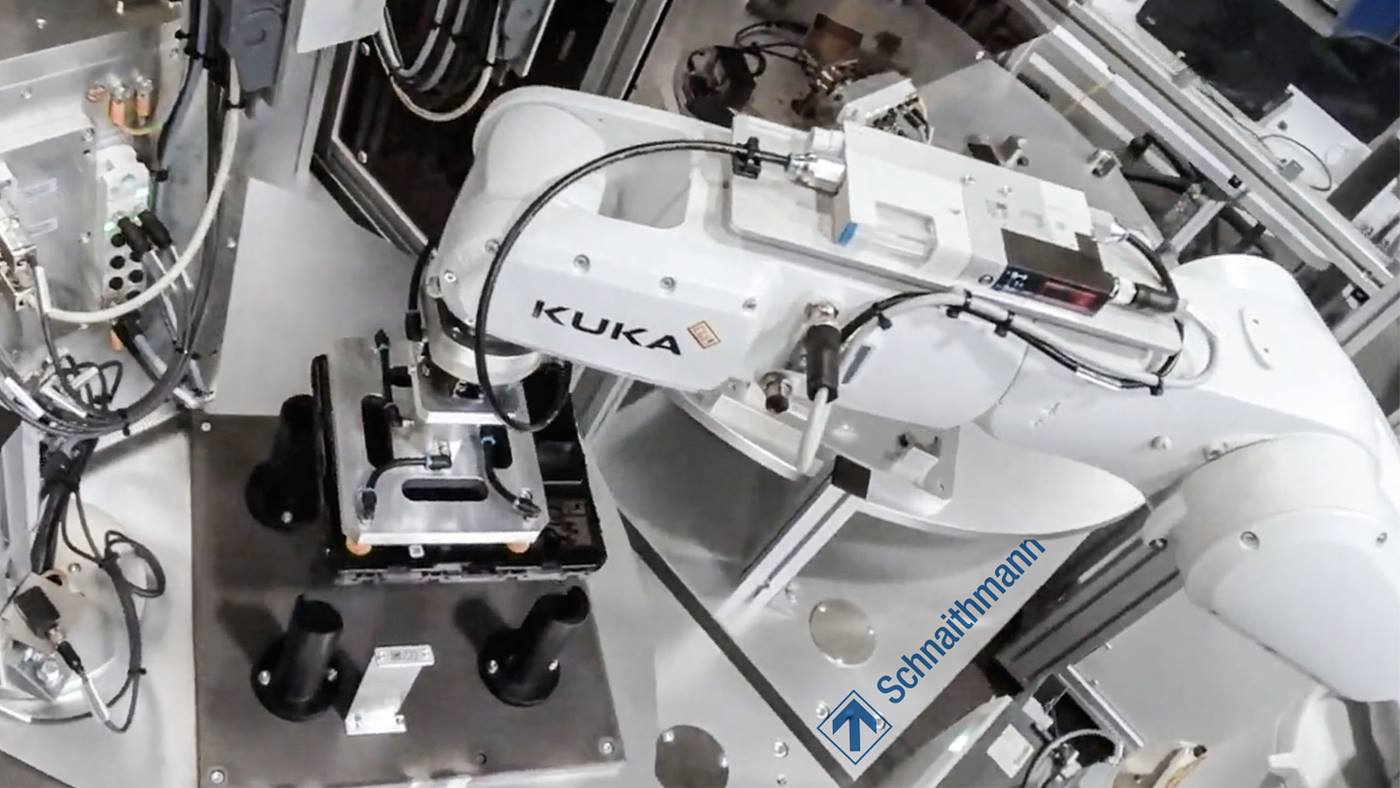

Suitable concepts for the intelligent manufacture of electric cars and integration into the production process are thus in demand. Suppliers have a major role to play here. That is because in this case, they not only provide prefabricated and precision-fit components, as has usually been the case in the past, but are also actively involved in the development process. One such company is automation specialist SAR from Dingolfing in Bavaria. Among other things, the company develops and produces manufacturing solutions for the automotive industry and its partners.