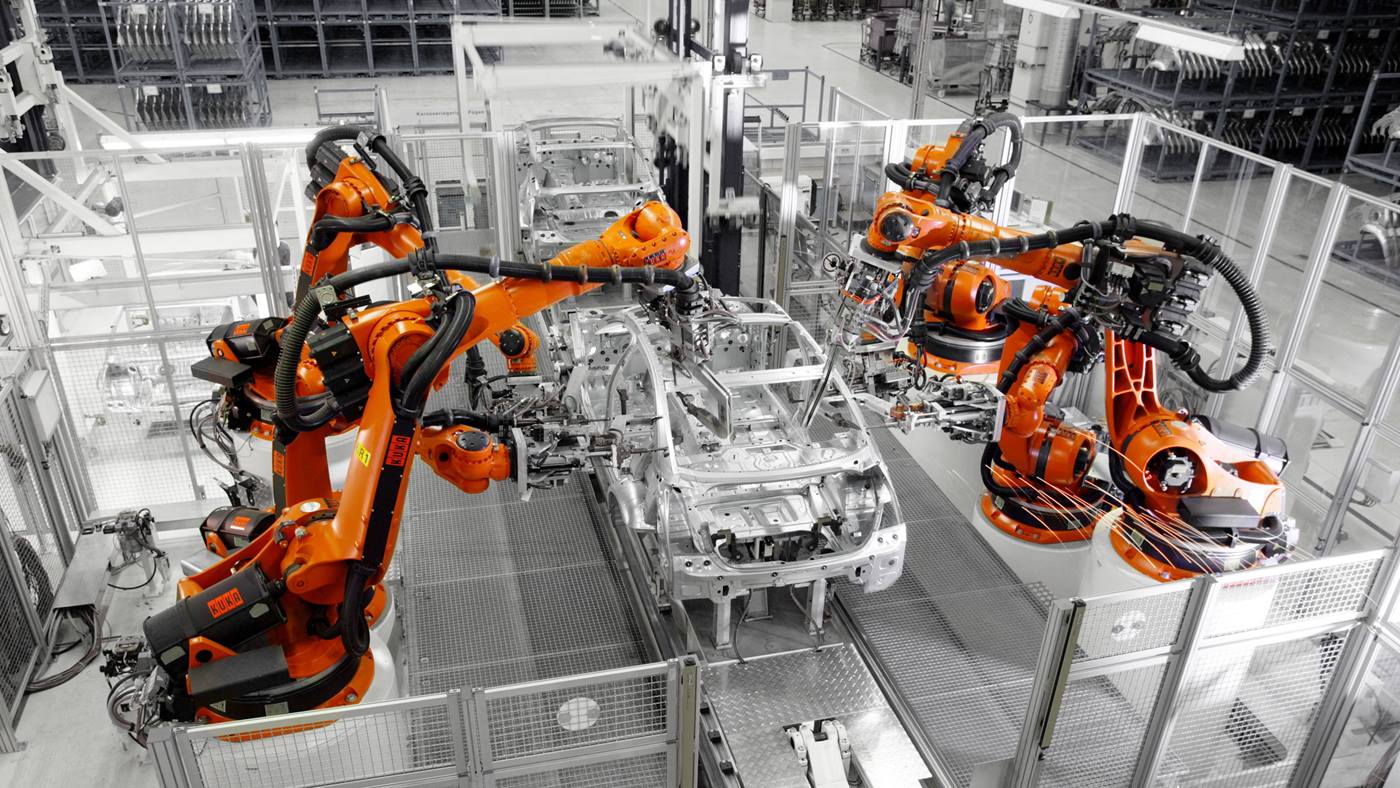

The KR C5 robot controller has been on the market for almost a year - and enjoys great popularity - especially due to its energy efficiency and the reduction of the Total Costs of Ownership (TCO). The KR C5 results in up to 15% lower energy consumption of a robot system compared to operation with previous controllers. In addition, its reliable and durable hardware and the Functional Twin, which makes it easy to switch to the new generation of controllers, ensure a reduction in the Total Costs of Ownership (TCO) and sustainability in production.

By the beginning of 2022 KUKA will deliver around 250 controllers to BMW in Dingolfing. "Work is currently in progress for the follow-up generation of the 5-series BMW G60, which is expected to appear in autumn 2023. The KR C5 smart robot controller will be used to support production in the area of the doors and flaps," says Sabrina Majovsky, Key Account Manager BMW at KUKA.

Future-proof and economical

The order from Bavaria was followed by extensive pilot tests, which started on site in July 2020 with the introduction of the prototype. "It was particularly important for us to raise the production to a new level. We attach great importance to the use of the latest technology and therefore decided early on, to put the new robot controller from KUKA into operation at our plant," says Markus Lehmann, Head of Plant Engineering - Robotics at BMW, explaining the decision. The KR C5 contains fewer hardware components than its predecessor, the KR C4. A quick exchange of the highly integrated control modules minimizes the downtime of the production line in the event of a fault. Another plus point: in future, the KR C5 will also enable the use of cloud-based services and iiQKA, the new robot operating system from KUKA.

Above all, the customer was impressed by the energy efficiency of the controller. Andreas Knöpfle, portfolio manager for the new controller generation at KUKA, measures this advantage in figures: "The energy consumption of a robot system is up to 15 percent lower when a KR C5 is used instead of a KR C4 controller."

Functional Twin: Easy integration, fast commissioning and minimal training effort

The Bavarian automobile manufacturer uses the KR C5 as an extension of the predecessor version KR C4, which continues to be used at other production stations. One advantage: both control versions offer the same functions and the same operating concept for the user. Therefore, the training effort for customers like BMW is significantly reduced.

Continuous improvement of the control system

Parallel to BMW, other customers from the automotive industry are also relying on the new generation of robot controllers. In addition, KUKA is already working on further installation options for customers, for example, for maximum flexibility in production. With the new KR C5 controller generation, KUKA is pursuing the goal of supporting its customers in implementing future-proof and sustainable production.