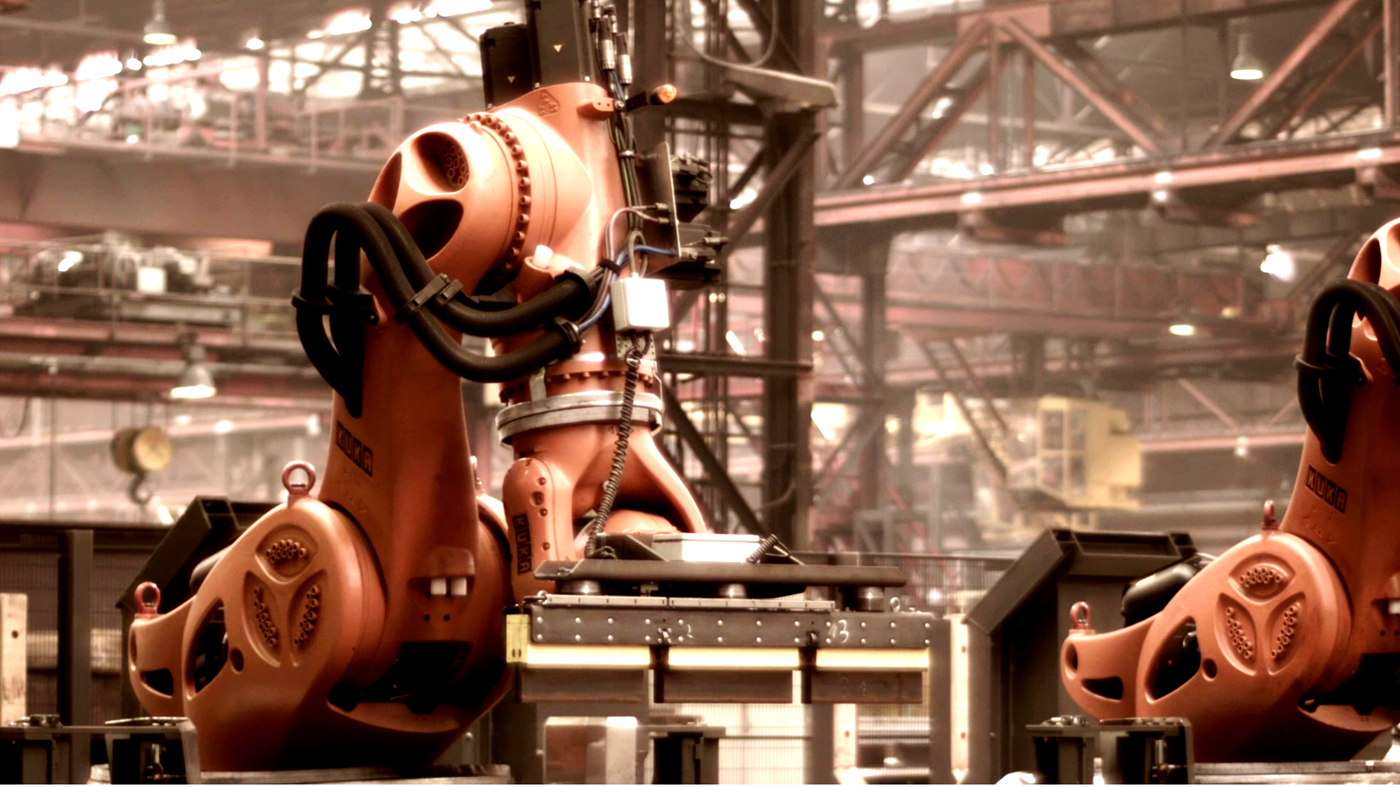

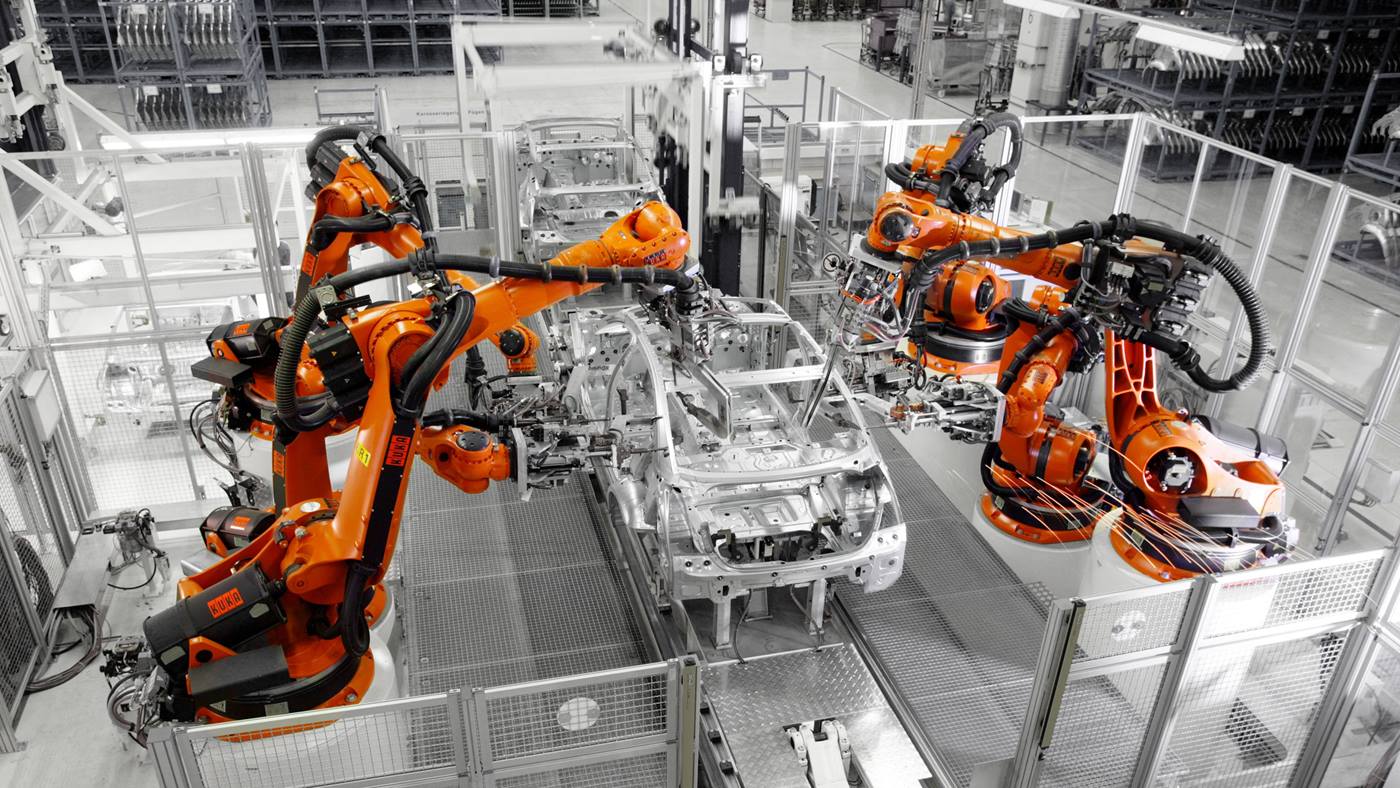

Due to the length of the special profiles – up to 26 meters – the robots must also be able to transport loads of about 2.5 tonnes. The result is a process that to date remains unique worldwide. A total of six robots are positioned next to one another in the automated system. In the first work step, the special profiles are delivered to the robots’ workspace by a conveyor. The robots grip the bars by means of magnetic grippers and stack them compactly on a stacking unit for onward transportation. Depending on the length of the bars, a corresponding number of robots perform the stacking. In this way, it is also possible for the robots to carry out the stacking in groups of three, thus enabling work to be performed twice as fast. Once the specified number of bars have been set down, the stack is moved forward by the next conveyor ready for shipment to the customer.