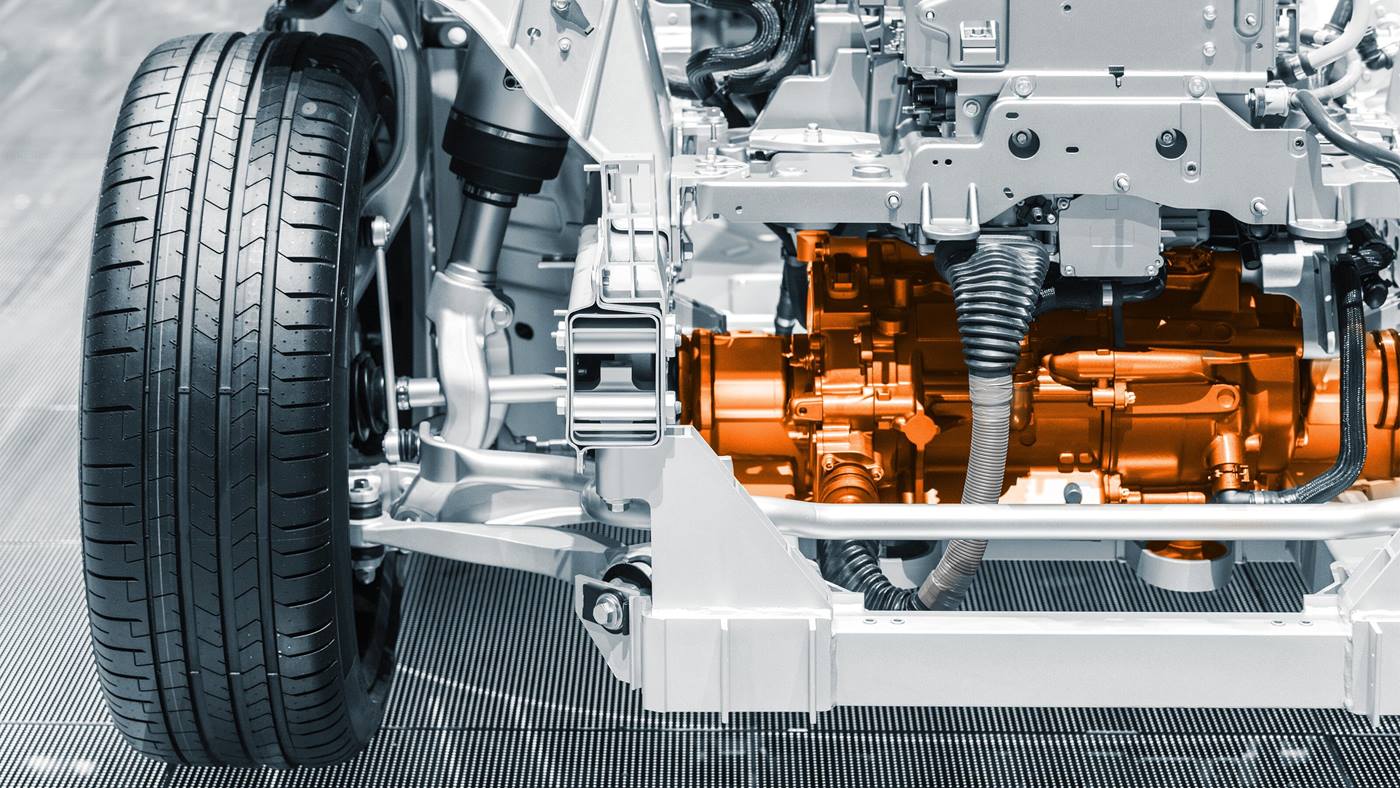

Environmentally friendly, resource-saving and efficient - mobility will be rethought in the future

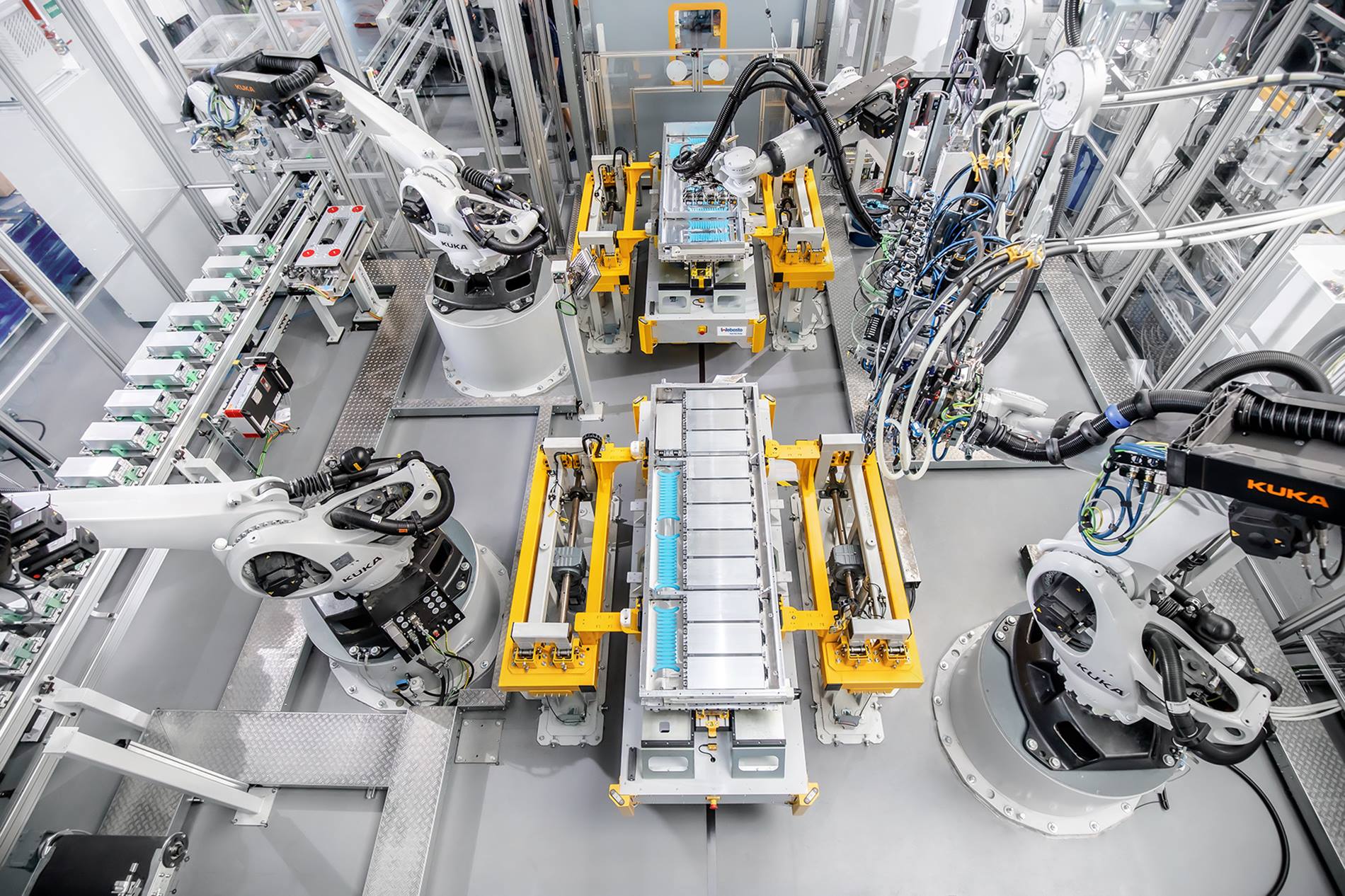

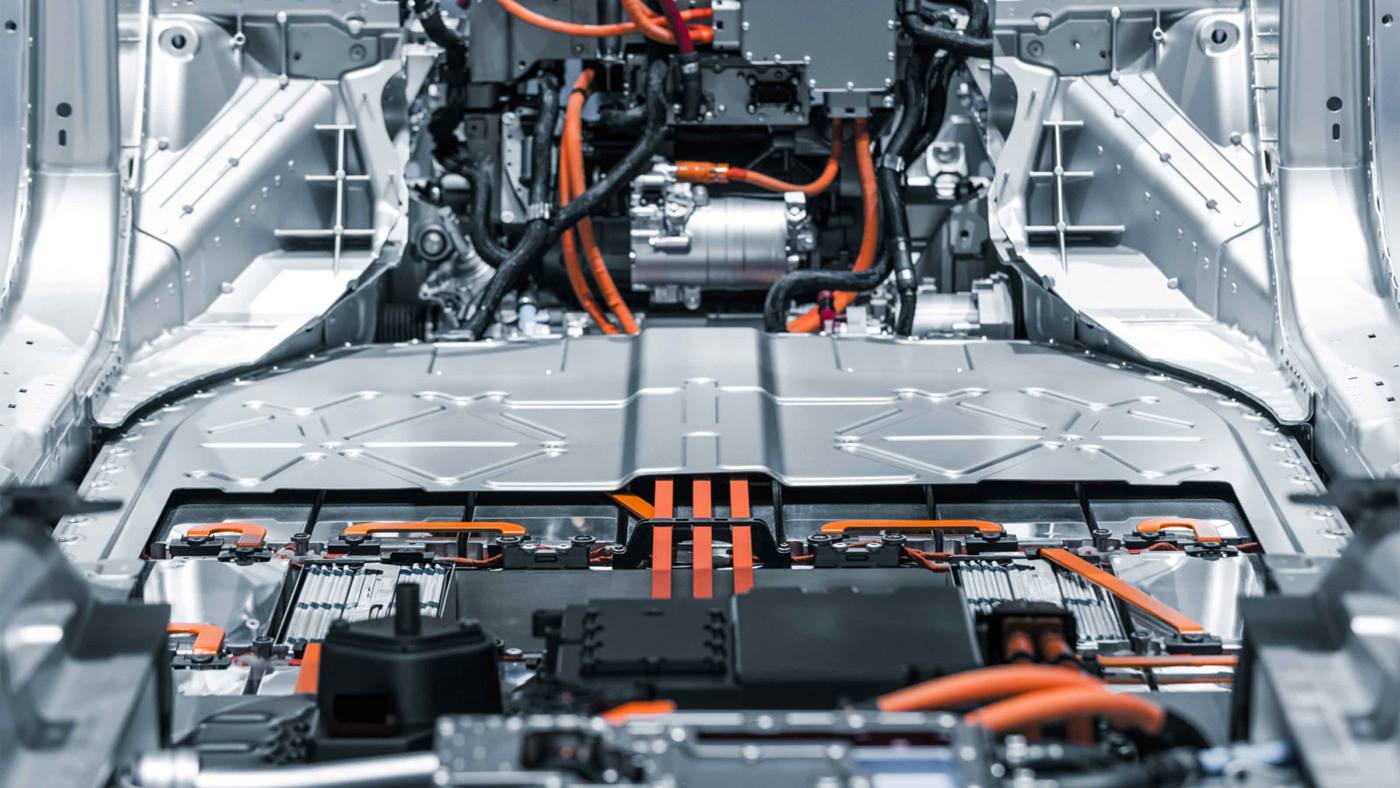

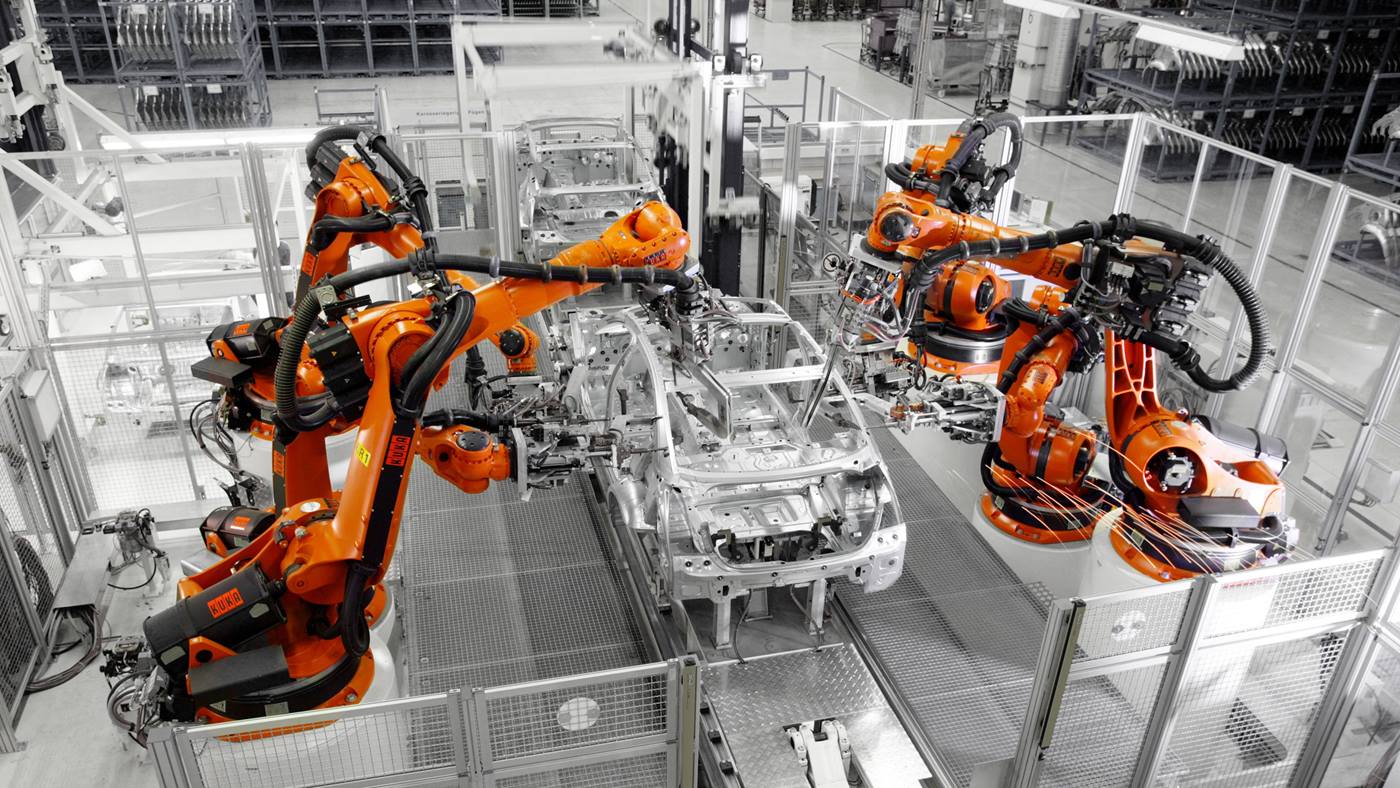

"We are opening a new chapter with battery production.", says Dr. Hartung Wilstermann, globally responsible for the battery business at Webasto. In 2016, the decision was made to expand the product portfolio: in addition to the core business with roof and thermal systems, the automotive supplier now also produces charging solutions and battery systems for electrified vehicles of all kinds. "As a long-standing partner of the automotive industry, we have been shaping trends and developments in the industry together with our customers.", says Wilstermann. To manufacture the variable range of battery systems, one of the most state-of-the-art production systems for battery systems was built in cooperation between Webasto and KUKA.