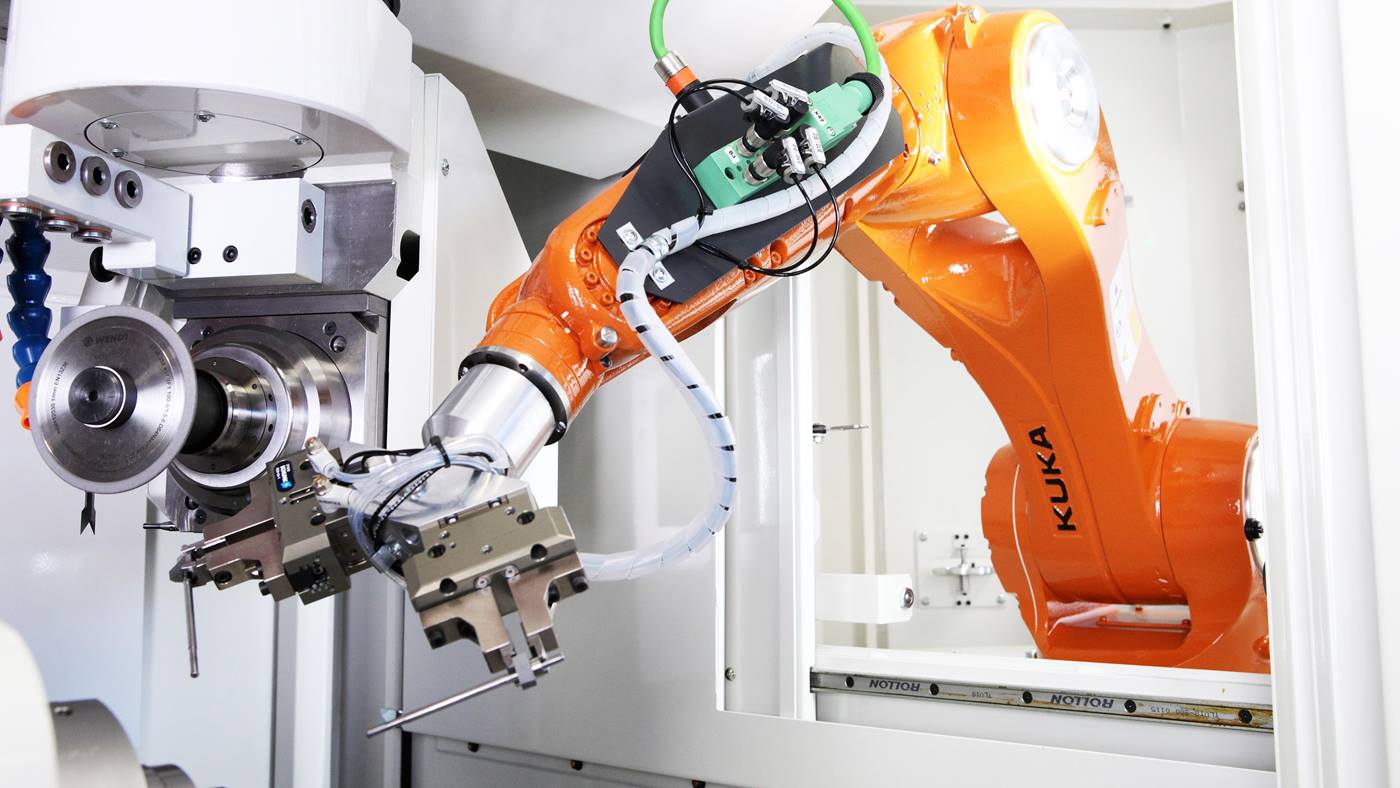

KUKA robot automates the machining of sheet metal parts

A KUKA robot from the KR QUANTEC ultra family enables the robot-based handling and deburring of sheet metal parts at a kitchen appliance manufacturer in southern Germany. The robot picks up sheet metal parts independently and feeds them to a grinding machine for deburring.

The automation potential in the metalworking industry has not yet been fully exploited. Companies view supposed interface problems and a lack of robot programming knowledge as major challenges. Together with KUKA, Kirchner Konstruktionen GmbH has developed a fully automatic robotic application that allows easy robot-based handling and deburring of sheet metal parts. The KUKA robot is also capable of machining 30 different sheet metal parts.

Automated deburring in six process steps

Initially, the robot is programmed for six work steps in all. Then the robot checks the parts which have been delivered before picking them up and placing them on a conveyor. The conveyor transports the sheet metal parts to the machine tool, where they are deburred. After the deburring process, the KR QUANTEC ultra independently picks up the parts from the exit conveyor before finally setting them down. In order for the high payload category robot to perform the automated machining of sheet metal parts, it must rely on the support of further KUKA components.

With KUKA application software: robotic machining of sheet metal parts from a single source

The visualization software KUKA.HMI zenon supports the operator in entering the type of sheet metal part easily into the controller. KUKA.VisionTech, a software package for object recognition, checks that the part has been delivered in the correct position. In addition, the software detects when the deburred part can be picked up again. The KUKA.ConveyorTech technology package ensures that the part is smoothly placed on the production line and conveyor. Safety is ensured by the KUKA.SafeOperation software. With the program, workspaces and protected spaces can be easily defined. This makes safe and efficient collaboration between humans and robots possible.

The robotic application enables our customer to optimize processes, machine various components and ultimately to improve the quality of the products significantly.