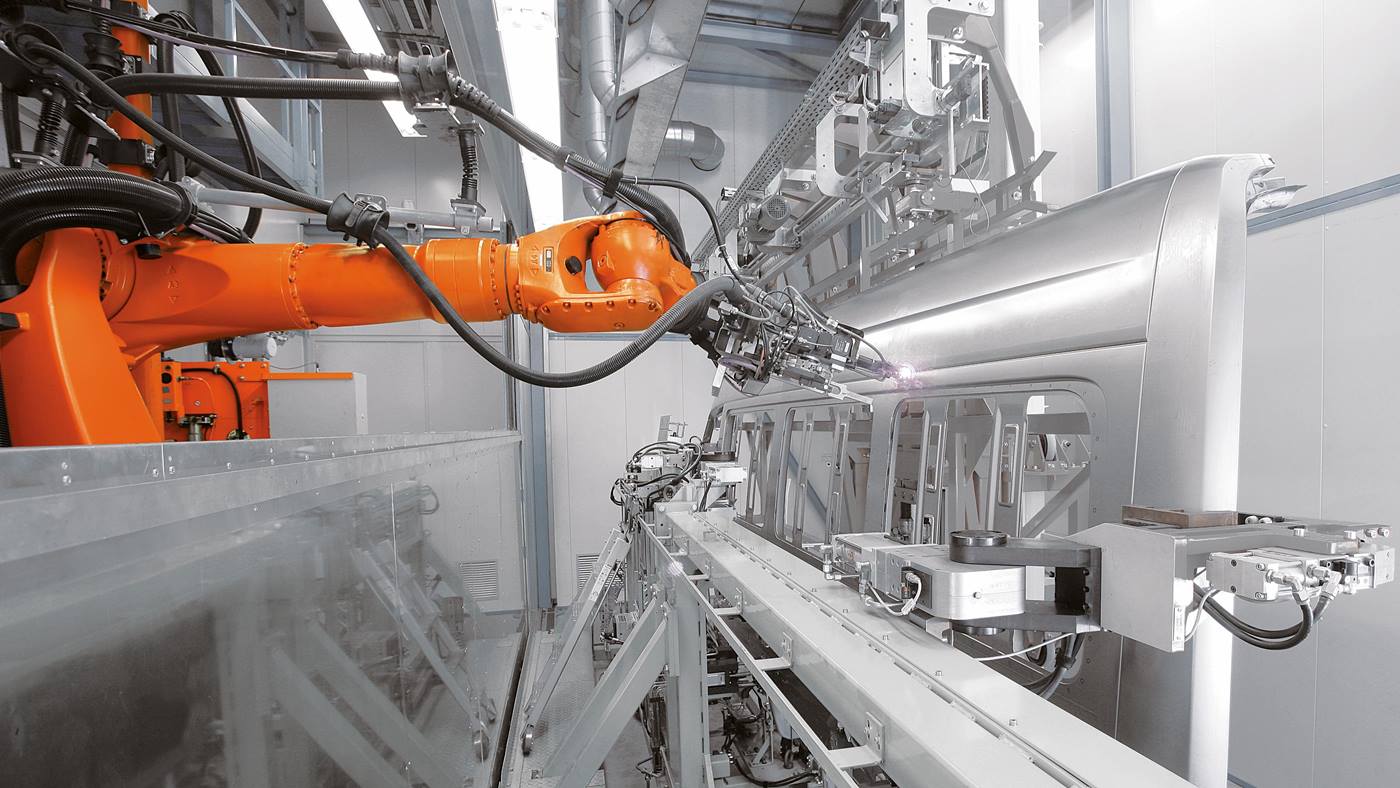

¿Cuáles son los argumentos a favor del uso de robots en las PYME?

La automatización no está destinada solo a las grandes empresas. Incluso las pequeñas empresas y medianas empresas (PYME) pueden ser más productivas y tener más éxito con la robótica. Les ayudan a prosperar a pesar de la escasez de trabajadores cualificados y les permiten convertirse en un empleador más deseable. Esto se debe a que los robots liberan a su equipo de tareas físicamente pesadas, monótonas y que requieren mucho tiempo. Ya con un solo robot, puede aumentar su productividad, ampliar su área de negocio y responder con flexibilidad a las peticiones de los clientes, incluso con lotes de pequeño tamaño.