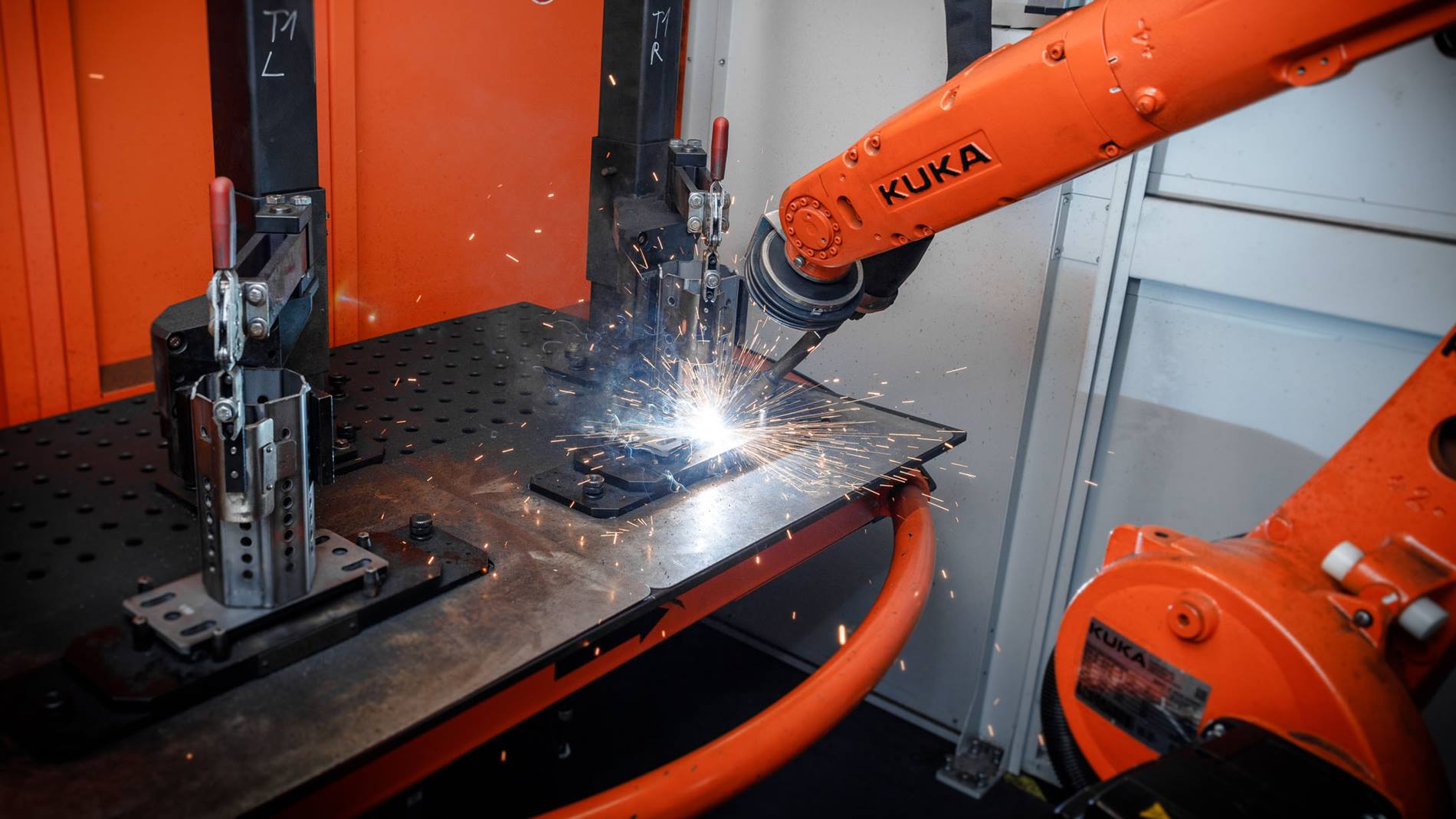

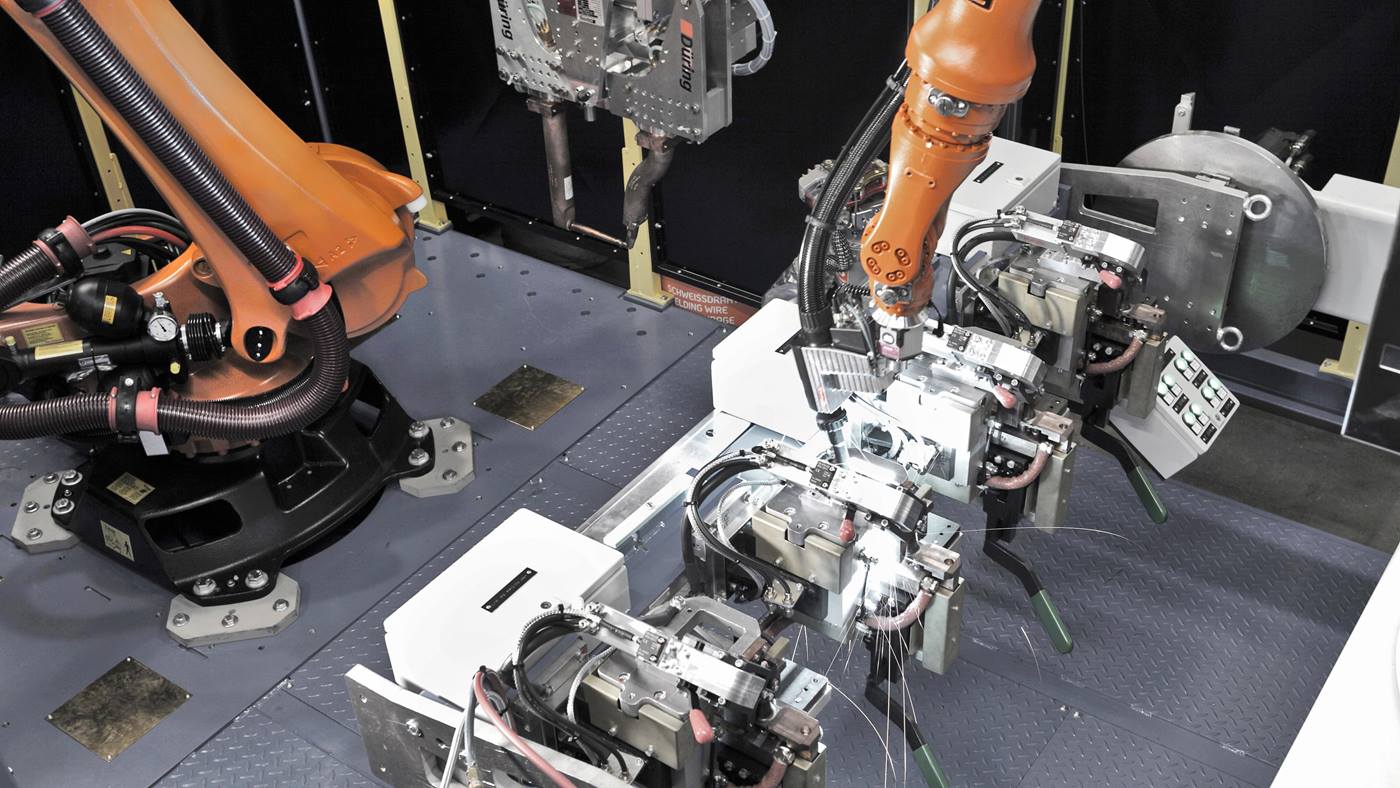

Impressive weld seams in a flash with a welding robot

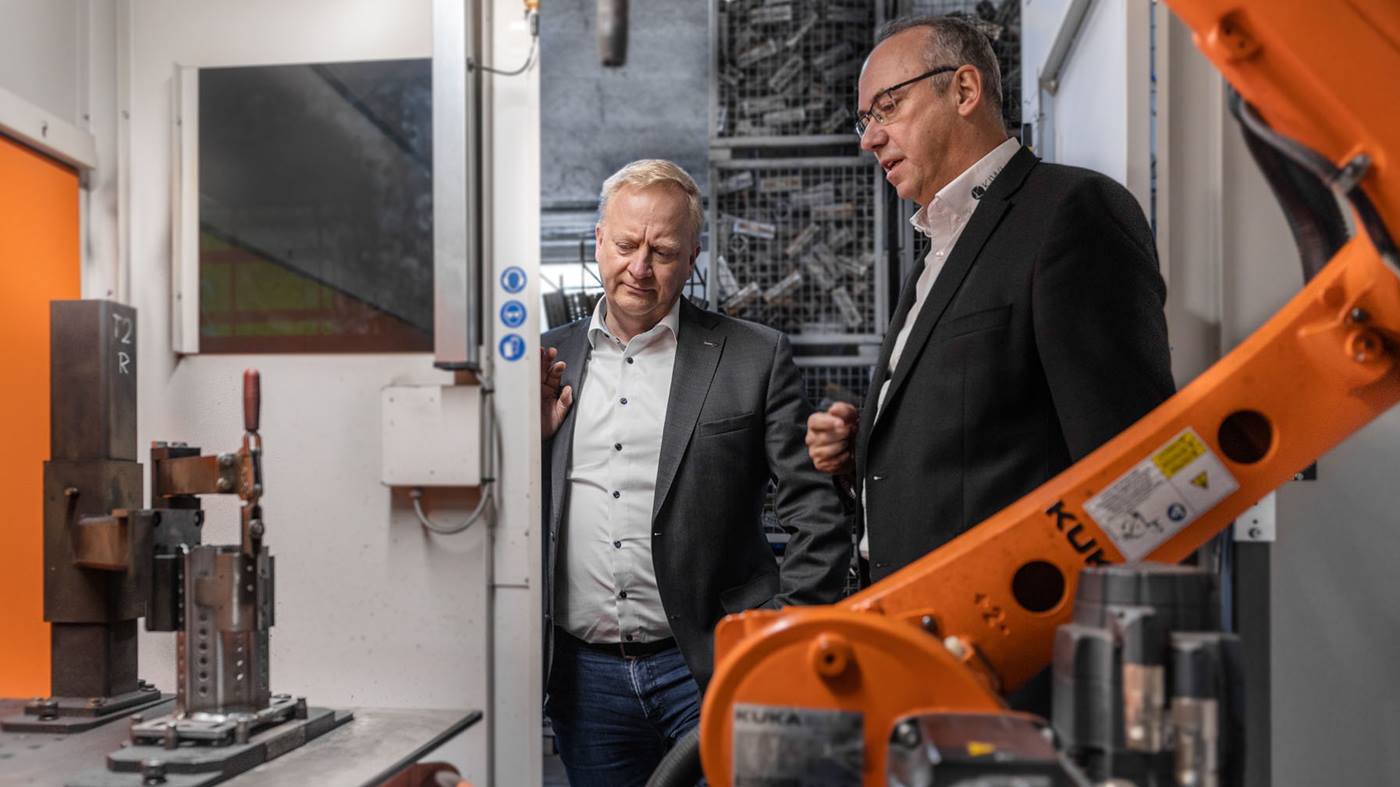

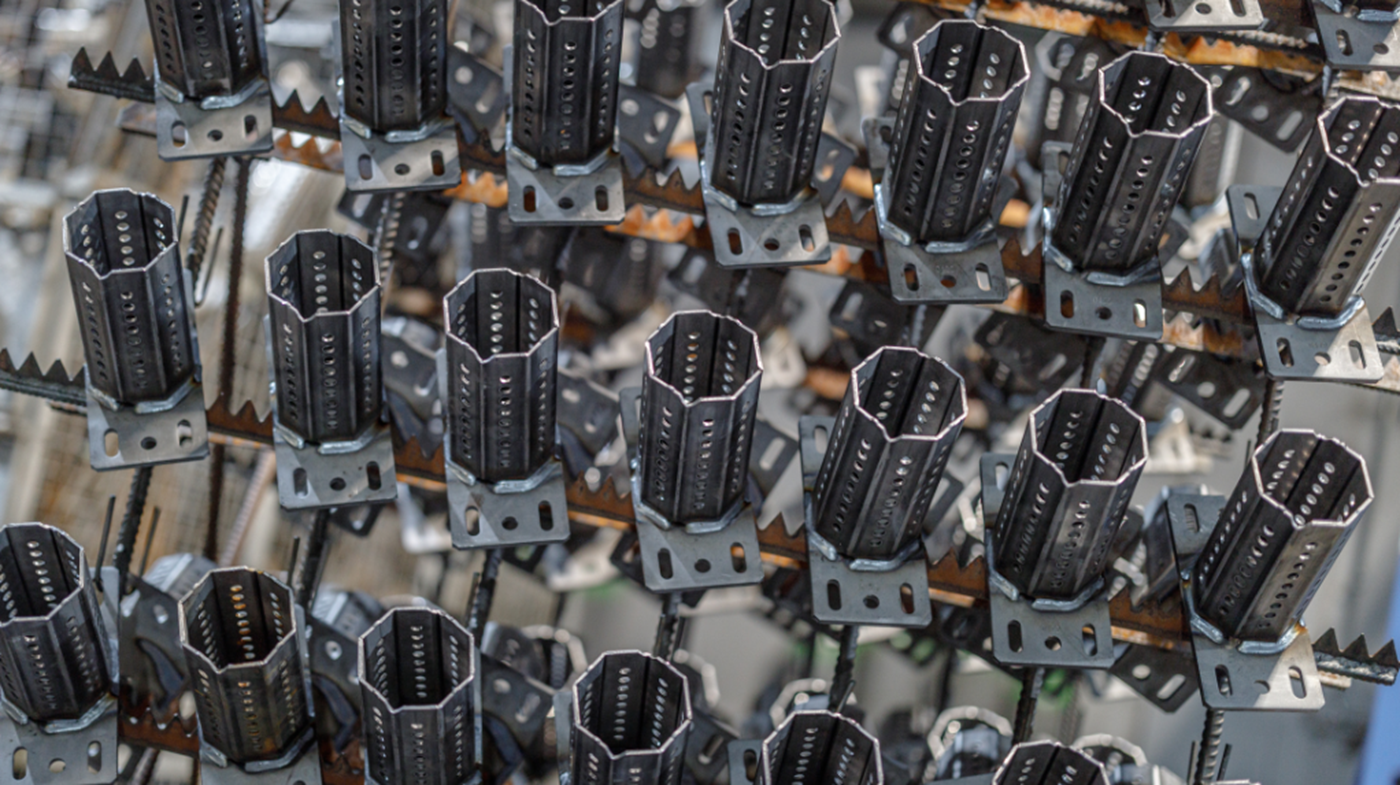

Few galvanizing plants also weld steel parts. Their core competence is hot-dip or centrifugal galvanizing to protect steel parts from corrosion. But in Sulz am Neckar in the Black Forest, Verzinkerei Sulz GmbH offers a lot more than that with its welding robot and cell. No one who sees the KR CYBERTECH nano at work would think this is unusual. With ease and precision, the robot uses a welding device to join an octagonal prism to a compact steel plate, completing two welding processes in a mere 90 seconds. An employee removes the finished products and replaces them with two new ones. “The quality of the weld seams is outstanding,” said Bernd D. Euschen, Managing Director of Verzinkerei Sulz, who is delighted with the robot-based solution featuring the KR CYBERTECH nano welding robot.