Robot-based plastic injection molding

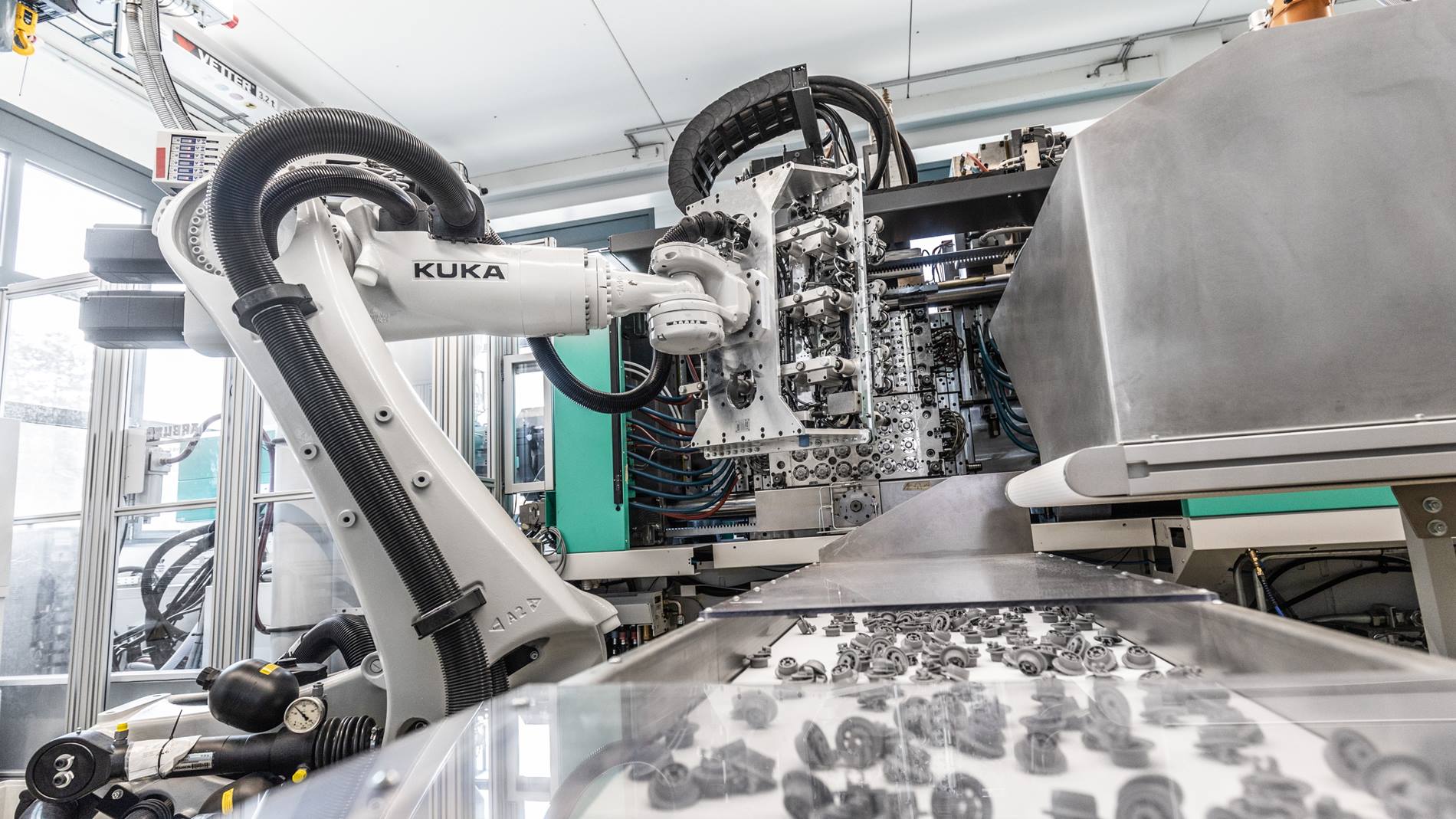

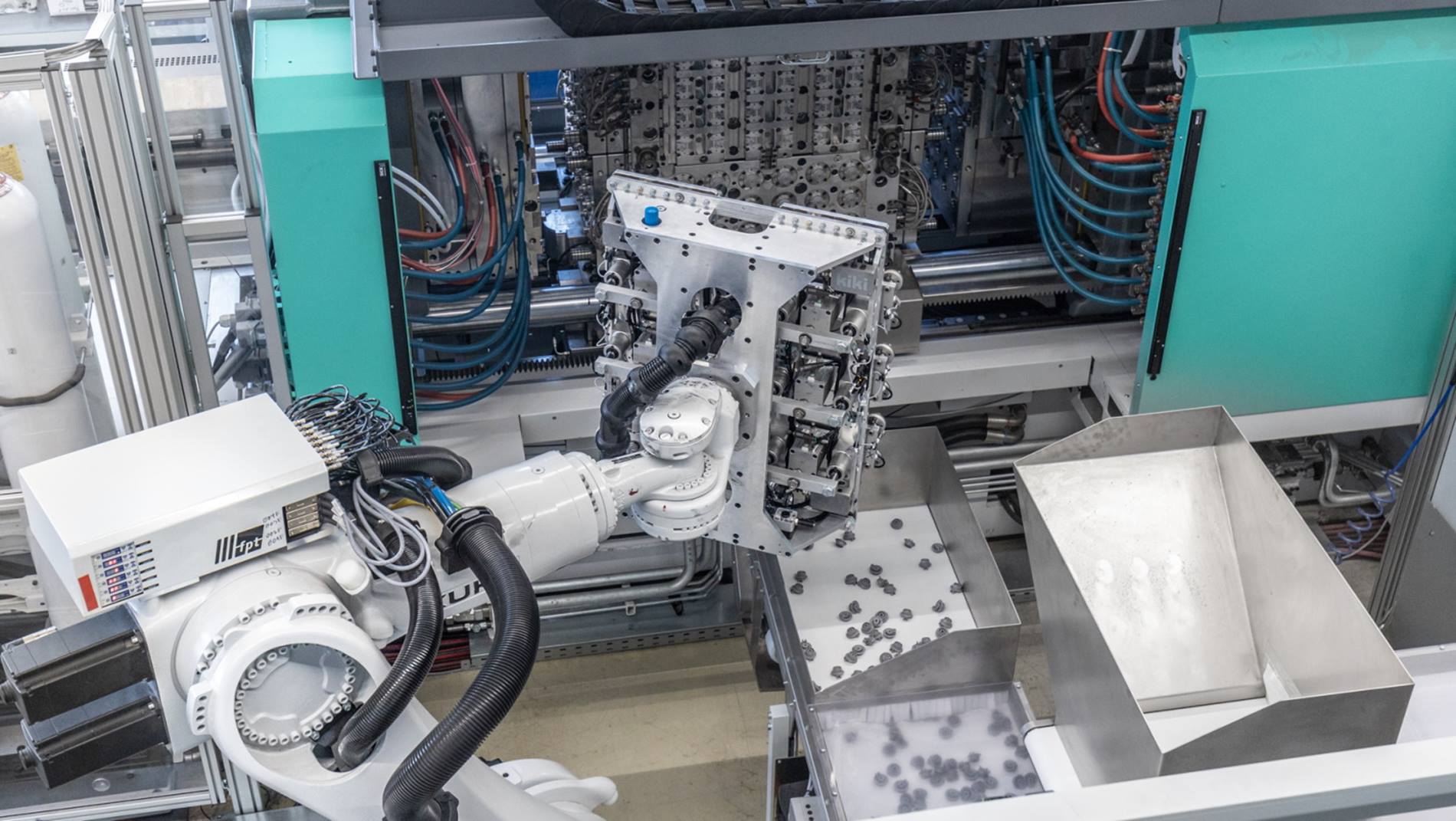

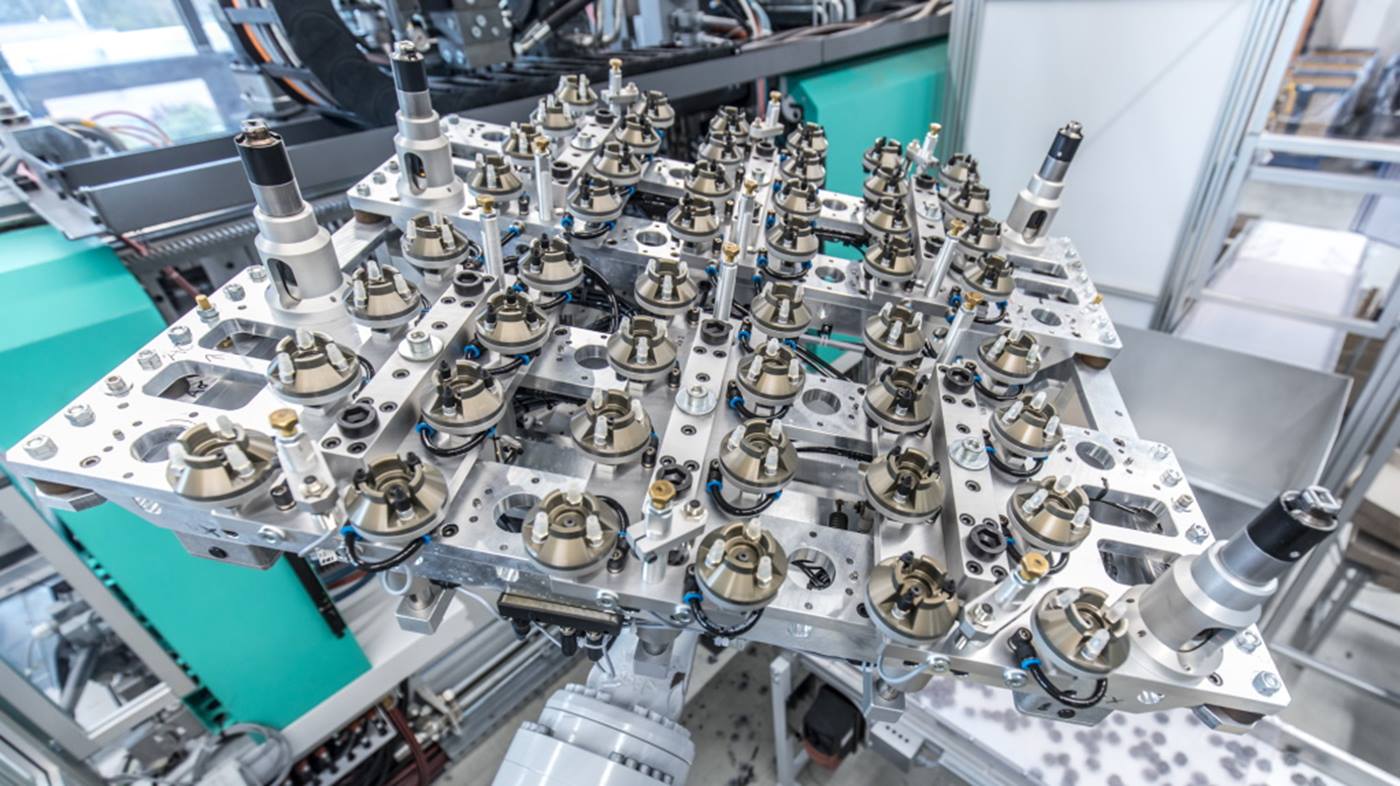

Plastics processing by injection molding is the ultimate challenge among injection molding techniques. Hauff, a family-owned company in southern Germany, fully automated the production of rollers for the upper racks of dishwashers. A KUKA robot and a multi-functional production cube made this achievement possible.

Unique large-scale system with injection molding machines

“Our system and all its associated processes are unrivaled worldwide,” said Jörg Vetter. “It saves us four to five injection molding machines and relieves our employees of monotonous production tasks.” Every year, Hauff uses the Cube to produce about 60 million components for BSH Hausgeräte GmbH alone. Over the next three years, production will ramp up to 75 million units.

Hermann Hauff founded the company in Pforzheim, Germany, in 1966. Today, still family owned, the company that bears his name produces high-quality precision injection moldings as well as injection molds under the direction of his daughters, Andrea Hauff and Carmen Hauff-Bischoff. Hauff’s customers come from the domestic appliance (white goods) sector, the automotive industry and the field of medical technology.

Hidden champion with the highest standards in plastic injection molding

An autonomous process based on one-piece flow

A customized machine for plastic injection molding

Bringing plastic into perfect shape with injection molding robots

Plastics processing with the KR QUANTEC PA

Error avoidance through simulation during planning

Automation of plastics processing with a spark of enthusiasm

With its extreme speed, the robot reduces production cycle times and increases manufacturing quality, without ever getting out of step.