Precision tool manufacturer automates CNC machine tending

The Paul Horn GmbH tool factory began, and designed and planned its own automation solution systems, including its gripper technology. Tübingen-based Horn then brought KUKA on board to program the robots and the PLC in the overall concept, including startup at global level. Today, Horn's specially developed systems for precision tool manufacturing are in worldwide use.

Challenges met with KUKA’s Customer Service on board

A software package and four robotic cells ensure enormous product diversity

KUKA thus became a programming partner for the Tübingen-based company. Sven Göckes, a robot programmer at KUKA for many years, was briefed on the ideas, and then configured and defined a uniform programming and software structure. “The goal was to program the solution to be so generic that we can expand the product diversity at any time,” said Göckes. “It wasn’t easy and it also roused my ambition.” Two years, many joint discussions and more than 4,000 programming hours later, fully developed systems for the various product families went into operation. One major success factor was the modular KUKA.AppTech software package, which perfectly matches Paul Horn’s production concept. The individual modules of KUKA.AppTech adapt easily to the various product groups, thus enabling repeatable and recurring programming sequences with minimal effort.

We place great importance on a modern, future-proof working environment. With solutions such as these, we aim to stand out from competitors in an economically strong region and motivate employees.

Automated machine tending: The right finish for every part

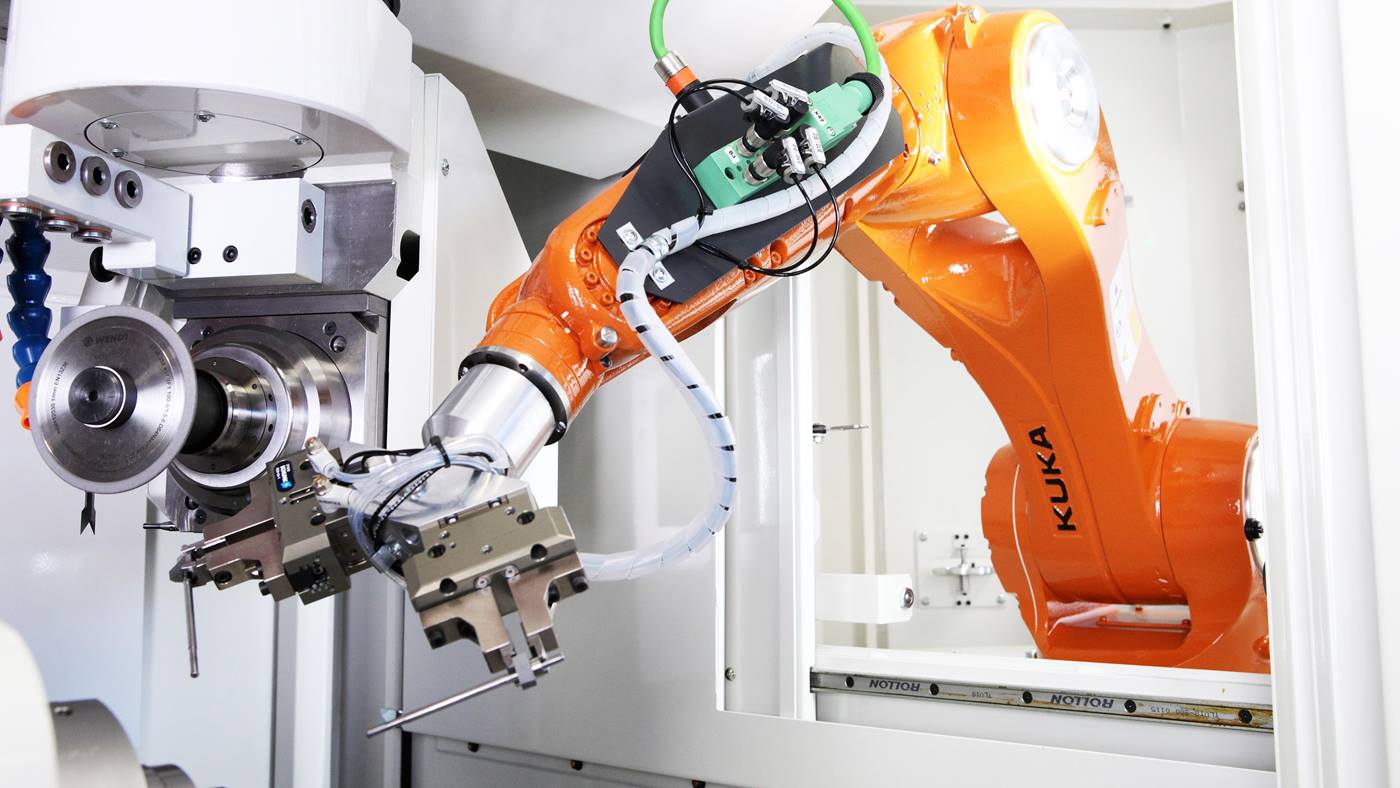

At Horn, the KR AGILUS hangs upside down from the ceiling of the cell within reach of the machine tool, where the robot can perform all its motions. From outside the cell, an employee loads a pallet and uses the operating panel to enter the corresponding parameters for the components located on it. The loading robot then begins its work. It aligns the indexable inserts on the pallet and grips it. The robot arm guides the workpiece to a camera station that determines the cutting position. With this information, the KR AGILUS positions the indexable insert on the carrier provided for this purpose, which transfers to the CNC machine in the next step for loading. The finish-ground indexable insert returns to the robot, which sets it down in its original position on the pallet. No time is wasted: While one workpiece is ground, the robot mounts the next on a new carrier.

Suitable for a wide range of components: Flexibility for the production of the future

Out of approximately 300 machines at Paul Horn GmbH, 55 now run the system developed by KUKA, which also sees use in the USA and the Czech Republic. Horn is set to advance its automation of machine tool tending further with another 27 KR AGILUS robots. “The main thing for us here is to have a long-term perspective,” said Managing Director Rommel. “With the new systems, we expect to be more flexible in the future and to be able to implement new product families ourselves. Working together with KUKA, we have created the basis for this.”

The right combination of software as a recipe for success

Horn used various KUKA software packages to ensure gripping accuracy and short cycle times during machine tending. For example, the modular software package KUKA.AppTech supported programming of the individual solutions while the simulation software package KUKA.Sim handled the safety configuration. With KUKA.SafeOperation, Horn also could carry out virtual definition of workspaces and protected spaces and monitor them in the real environment after implementation.

The use of robotics in our production facilities simplifies our everyday work. The automation has enabled us to achieve greater accuracy and speed. Moreover, the application is very intuitive to operate.

Modern working environment, motivated employees

The new automated tending solution from KUKA enables Horn employees to place even greater focus on their core task of ensuring high-quality grinding technology. With the miView visualization system from KUKA, Horn can generate and visualize operator control and display data in several languages directly from the PLC program, based on user settings and username and password entry. The miView package also automatically records and saves status information. Managing Director Matthias Rommel is certain that this project represents only a first step and that many more will follow, with KUKA as a trusted partner.