Robotic handling

With our handling robots, suitable software packages and a comprehensive range of services, we offer optimally tailored robotic handling solutions for virtually every sector: From assembly and pick & place to material transport.

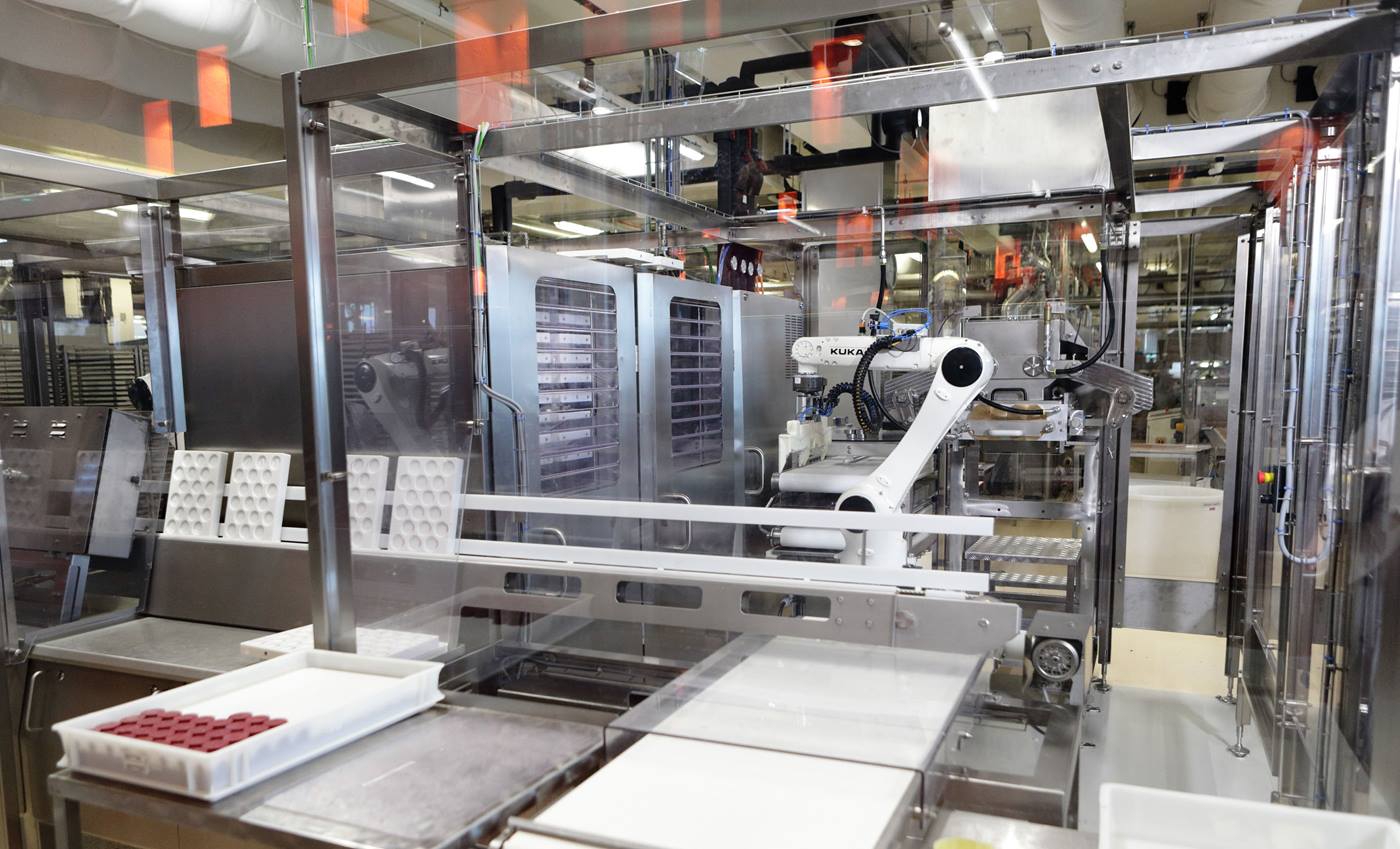

Handling robots for industrial sectors with high requirements

Expertise in every handling process

We offer a large variety of automation solutions for a wide range of different handling processes, which we can precisely tailor to your production. From bin picking and palletizing to transport:

Material transport

In a manufacturing process, it is important that products get from A to B smoothly, quickly and efficiently. From automated guided vehicles to mobile robots and navigation systems, we equip you with all the components you need for a smooth transport process.

Bin picking

In bin picking, structured, semi-structured, or chaotically distributed objects are gripped and then set down at a desired drop-off point. For this purpose, the robot requires a precise vision system. KUKA offers a selection of reliable software options for object recognition, such as KUKA.SmartBinPicking. This guarantees smooth handling, for example of bulk materials of any kind – also in your production facility.

Pick & place

In pick-and-place applications, components are picked up, positioned and placed. It is one of the most commonly used processes in manufacturing. With the intelligent KUKA.PickControl software package, which is specially tailored to picking and packing tasks, in combination with our wide range of robots, you can increase the possibilities of this application many times over.

Palletizing

Automated palletizing involves the sorting of goods on a pallet, which is used, among other things, to simplify transport and to bundle groups of goods. KUKA offers various forms of palletizing: mono-palletizing, mixed palletizing, depalletizing and cold storage palletizing.

Our KUKA.PalletTech software package offers a cost-effective palletizing solution that focuses on mono-palletizing.

Packaging

Packaging is the wrapping of a product to protect it from its environment. We offer several robots for this purpose. Our top models are the KR QUANTEC, which can be equipped with a bendable vacuum gripper for precise carton folding, and the LBR iiwa cobot, which is mainly used for folding and stapling corrugated blanks.

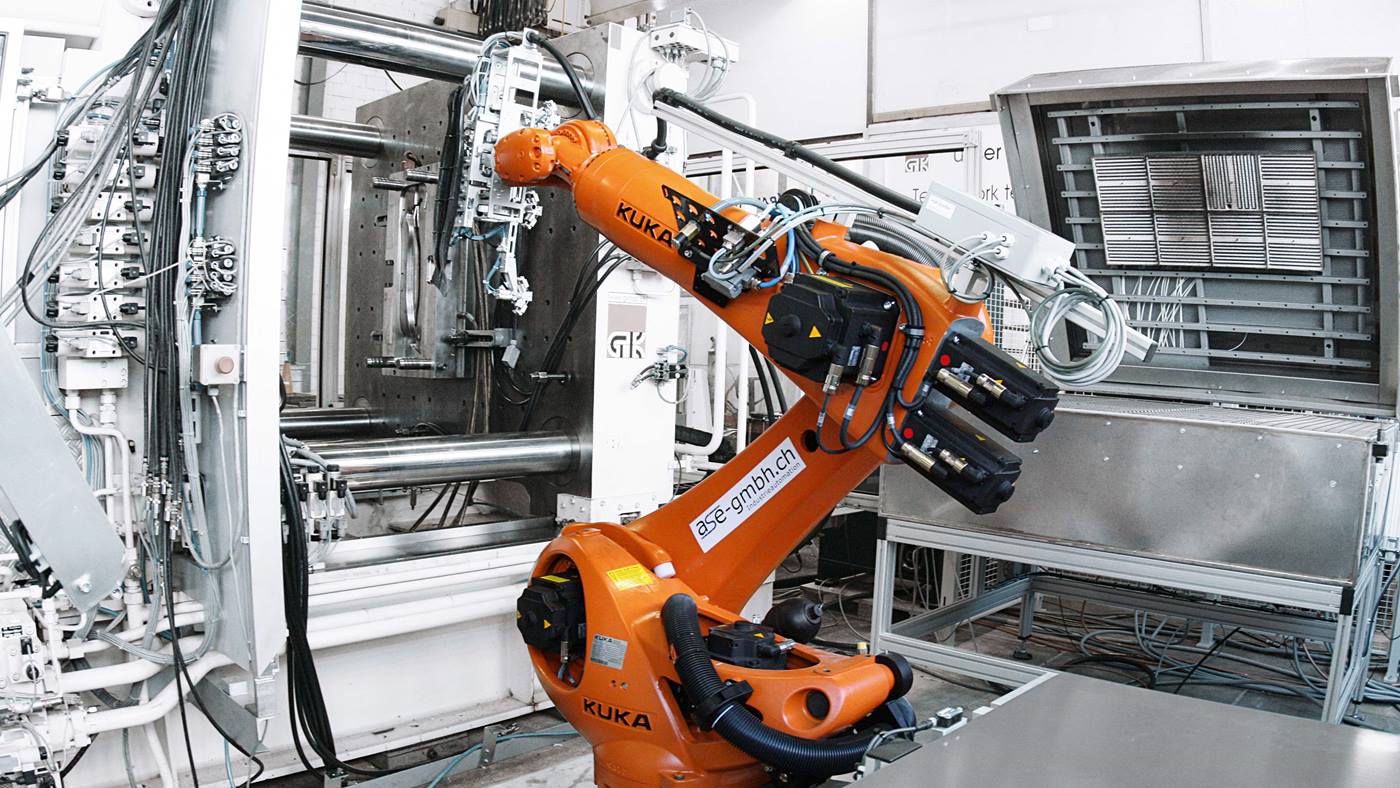

Linking

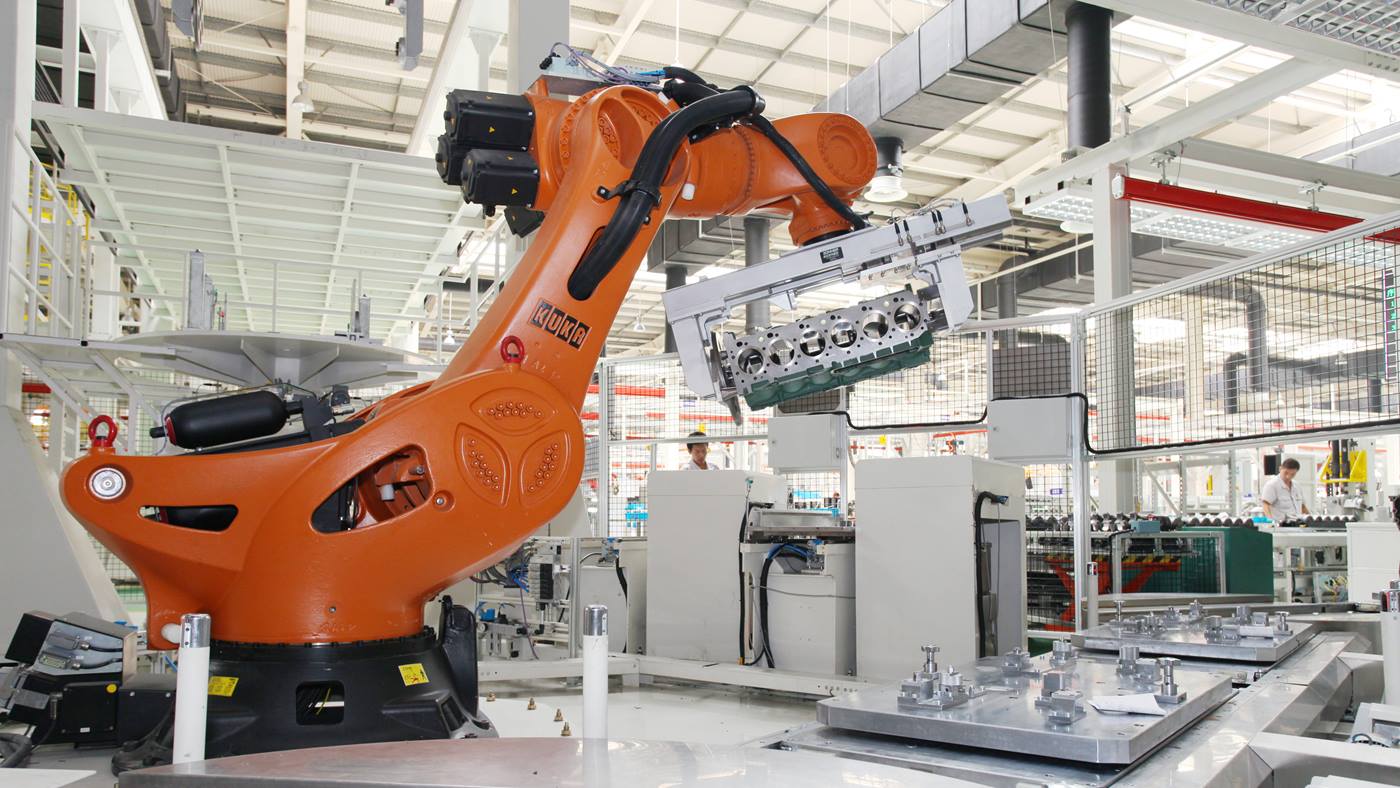

Loading and unloading of machines

Machine tending is a monotonous and repetitive task that can be optimally automated using our robotic systems. Our robots can handle the loading and removal of parts in the machine, the handling of pallets with a zero clamping system, and the opening and closing of machine doors. This enables, among other things, the automated control of CNC machine tools. In robotic tool handling, tools can be changed directly on the machine or with the aid of an internal tool changer.

Assembly

Industrial assembly is one of the core tasks in manufacturing and production. With our robotic systems, you can automate not only the handling of workpieces and quality assurance, but also handling tasks between assembly steps. Collaborative robots such as the LBR iisy and LBR iiwa cobots enable safe working without fences (Human-Robot Collaboration, HRC).

Software options for any handling task