Friction stir welding (FSW): the process

Friction stir welding is a process in which a rotating pin is traversed along the contact surfaces between the workpieces. The frictional heat plasticizes the material, which is welded together.

The FSW process is particularly suitable for joining non-ferrous metals with a low melting temperature and for mixed-material joints. Even materials that are difficult to weld or dissimilar materials such as aluminium with magnesium, copper or steel can be friction stir welded.

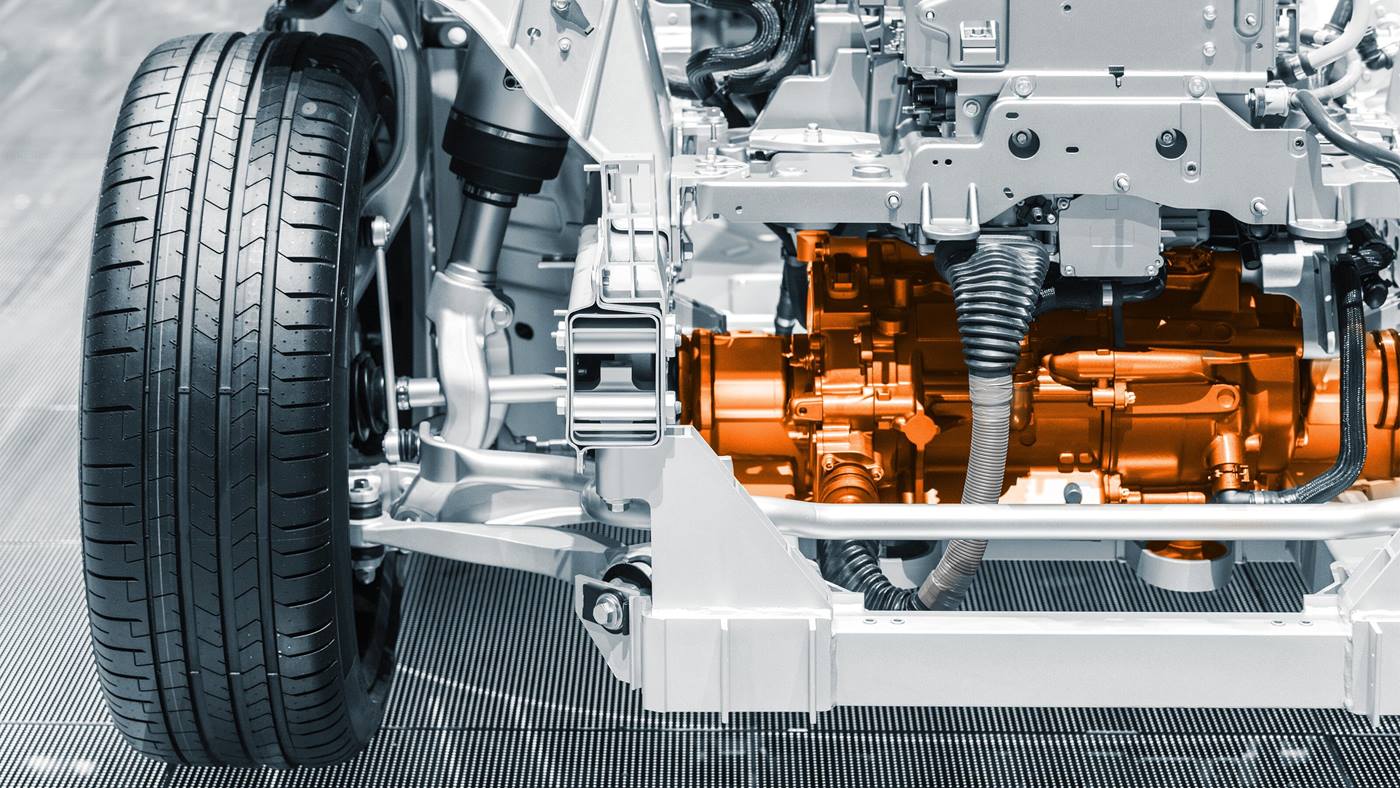

Friction stir welding in electric mobility – flexible and cost-efficient

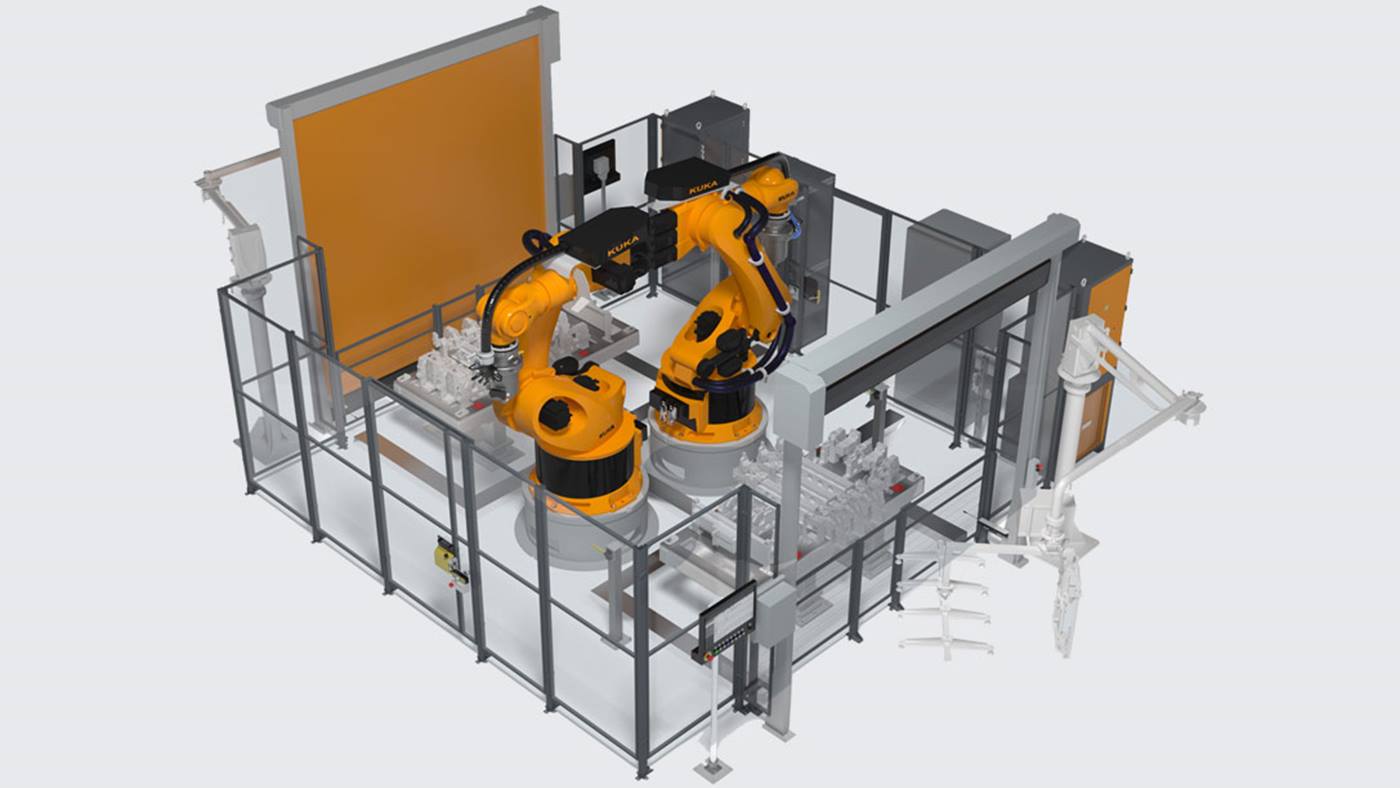

In electromobility, friction stir welding has become firmly established among many OEMs and Tier 1 suppliers, particularly for welding battery housings for electric (EV) and hybrid (HEV) vehicles. The weld seams reliably meet the high requirements for tightness and crash resistance. Robot-based friction stir welding also offers high flexibility at comparatively low investment costs compared to conventional gantry systems. For the production of electric vehicles, KUKA offers a modular friction stir welding cell – a modern and economical solution that can be easily adapted to different production requirements.