In addition to introducing their products rapidly to a global audience, manufacturers of cosmetic and skin care products, and their customers too, now also seek cost-efficient and eco-friendly packaging solutions.

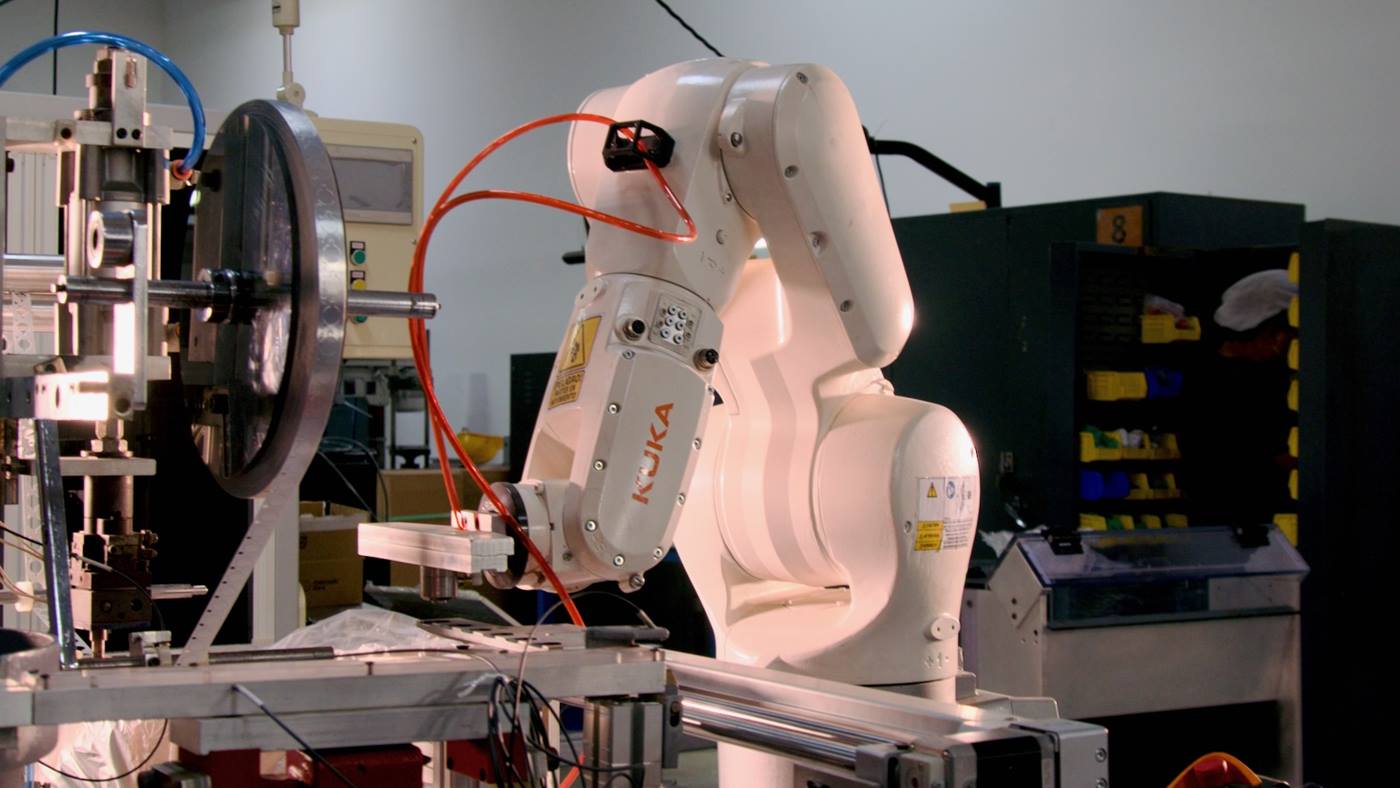

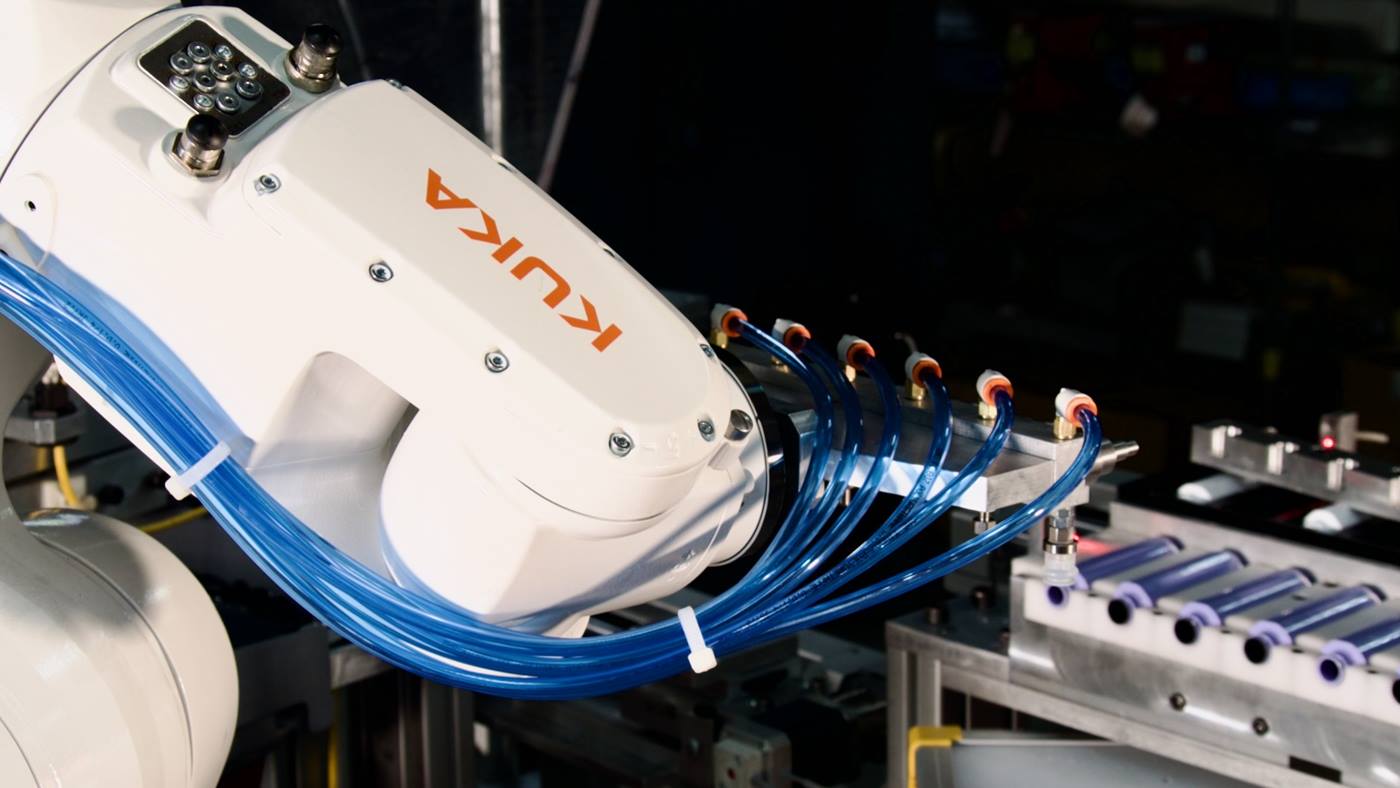

Environmental sustainability and biological hygiene are also at the front of consumers’ minds. For one leading producer of plastic beauty and personal care product packaging, automation is the key to meeting its goals of increased production speed and maintaining sustainability in manufacturing operations.