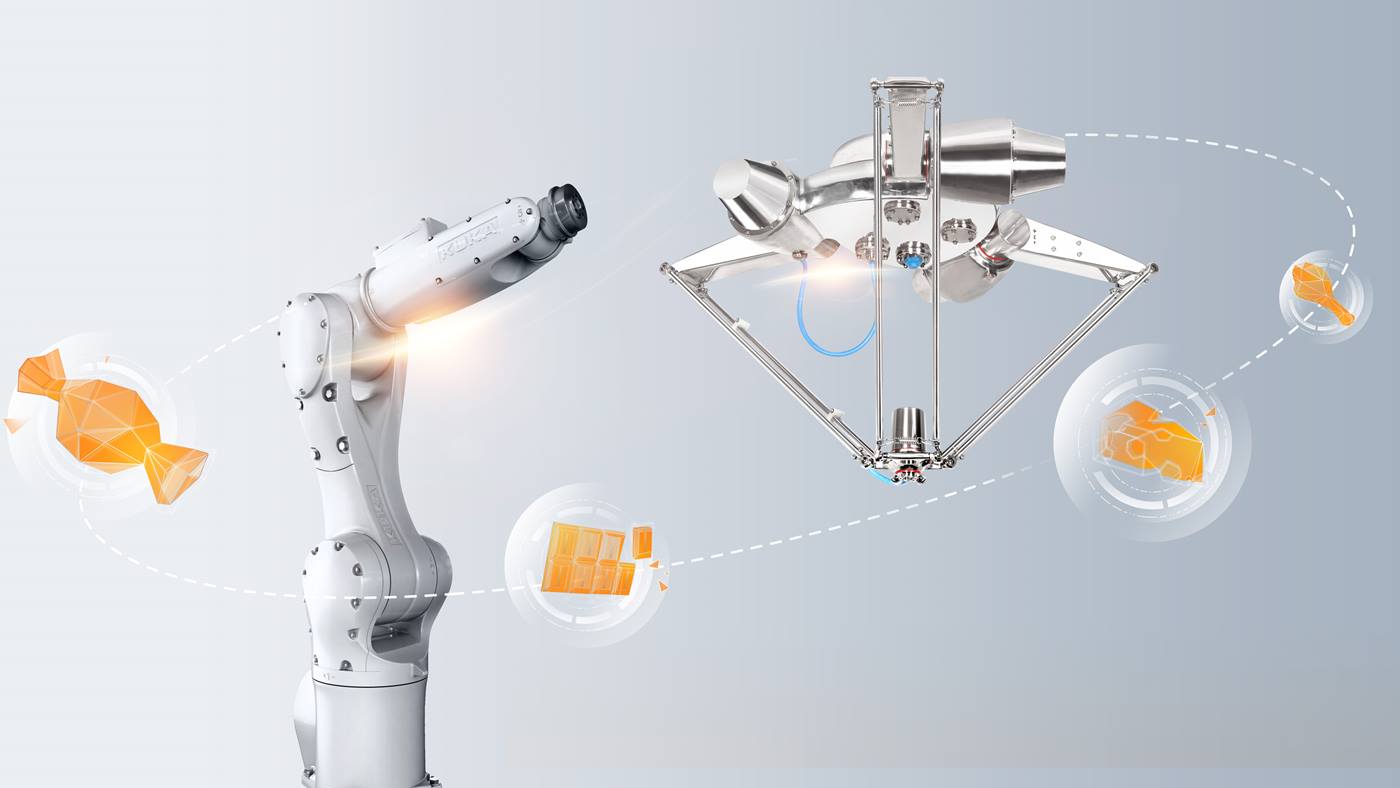

With a globally unrivaled portfolio of palletizing robots, KUKA stacks up well against the competition

KUKA offers some of the fastest palletizing robots on the market in a unique variety of types. With payload capacities of 40 to 1,300 kg, these robots offer excellence in the food industry's most demanding palletizing and depalletizing tasks.

November 19, 2021

Future-oriented automation: quickly getting to grips

KUKA designs each individual robot type for demanding palletizing and depalletizing tasks. For businesses, this means short cycle times and increased throughput, combined with low space requirements and high cost effectiveness. The smallest power pack among the KUKA palletizing robots, the KR 40 PA, offers a reach of 2,091 mm. Its 4-axis kinematic system stacks pallets to a height of 1.6 m – with a working speed of up to 56 cycles per minute.

Making light work of heavy tasks – and more

Robot and software: an unbeatable team