Katoen Natie

Katoen Natie was founded in 1854 in the Antwerp harbour. At that time the company was mainly active as guild and in storage and transport management. Due to its technological developments, Katoen Natie soon became a world player for supplying logistical and semi-industrial services to various sectors and ports. The excellent quality of their services and the continuous monitoring of the costs, form the basis for their long-term customer relations. The strength of their concept is the combination of engineering, technology, logistics and semi-industrial services. The technological solutions of Katoen Natie lead to serious cost savings for its customers.

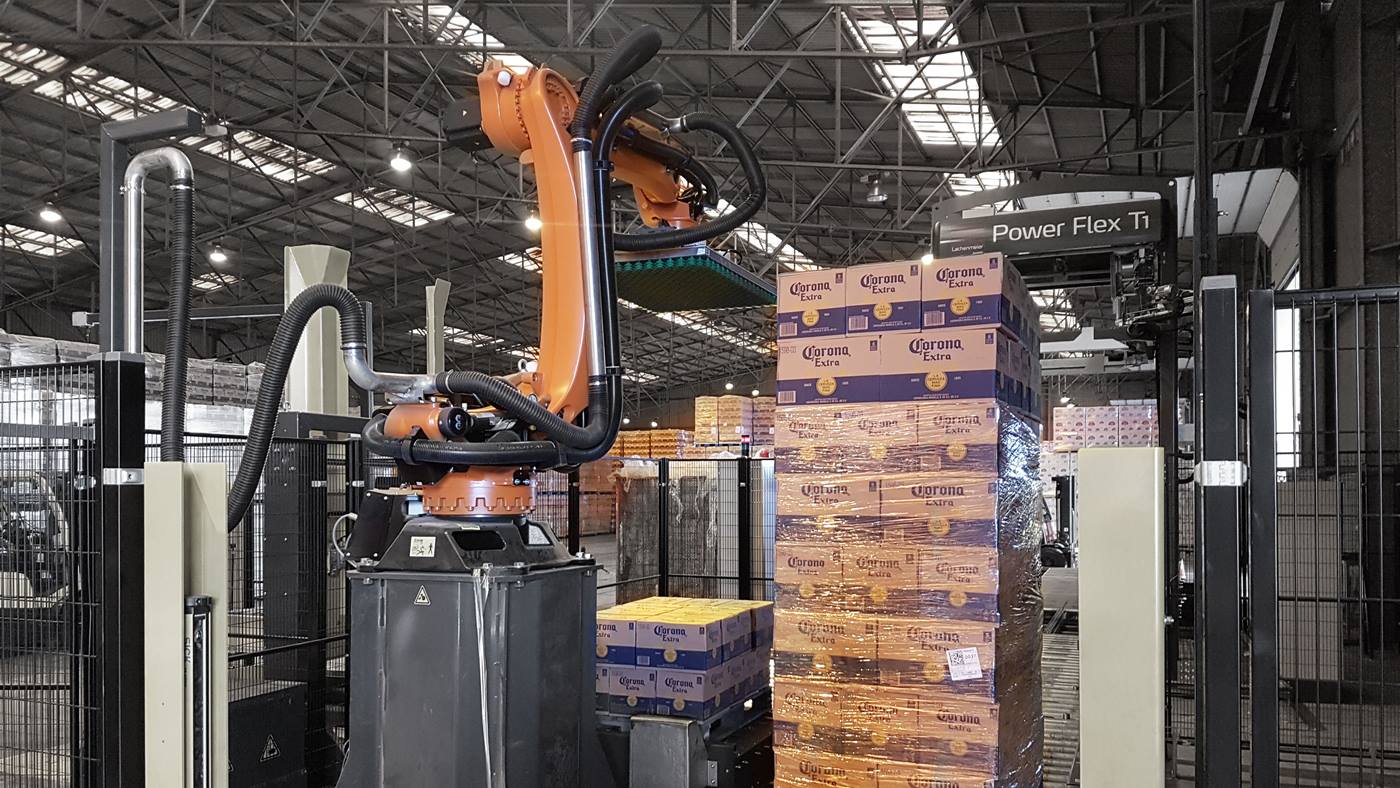

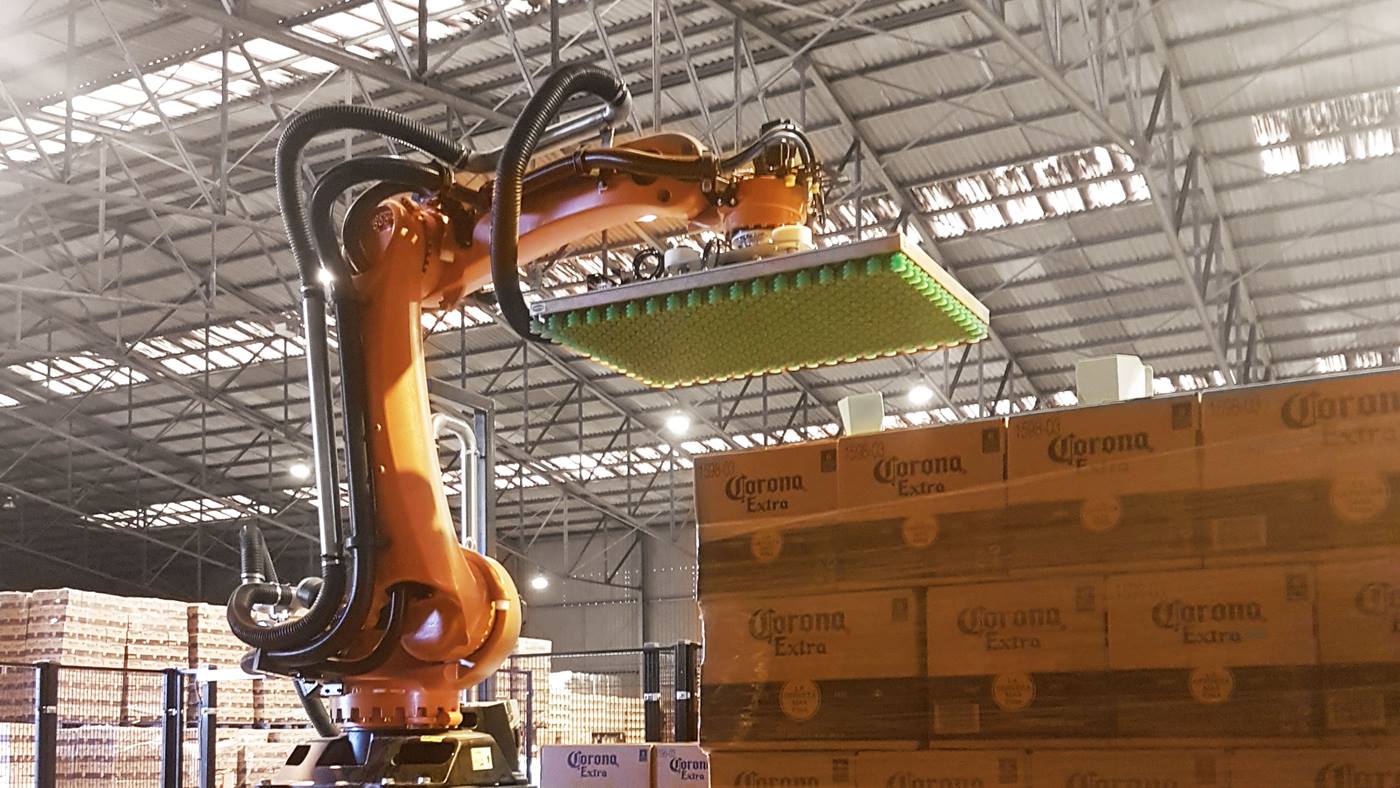

Katoen Natie currently consists of 400 operational units with 150 terminals and logistics platforms that provide work for more than 10,000 people around the world. One of the customers of Katoen Natie is the world player in beer brewing, AB Inbev. AB Inbev brews for example the brands Budweiser, Stella Artois, Jupiler and Corona. The company is ranked first or second in many of the world's leading beer markets. Katoen Natie is responsible for shipping the containers with Corona beer in Antwerp for AB Inbev. Corona beer is delivered on pallets consisting of 8 layers of beer crates. The problem that Katoen natie experienced was that for European transport, the pallets had to be depalletized until a height of 6 layers.

.jpg?rev=4b208640cafe40a081509063981fe9b9&w=1900&hash=5941C766F8F50393BB985628D32C6D5E)