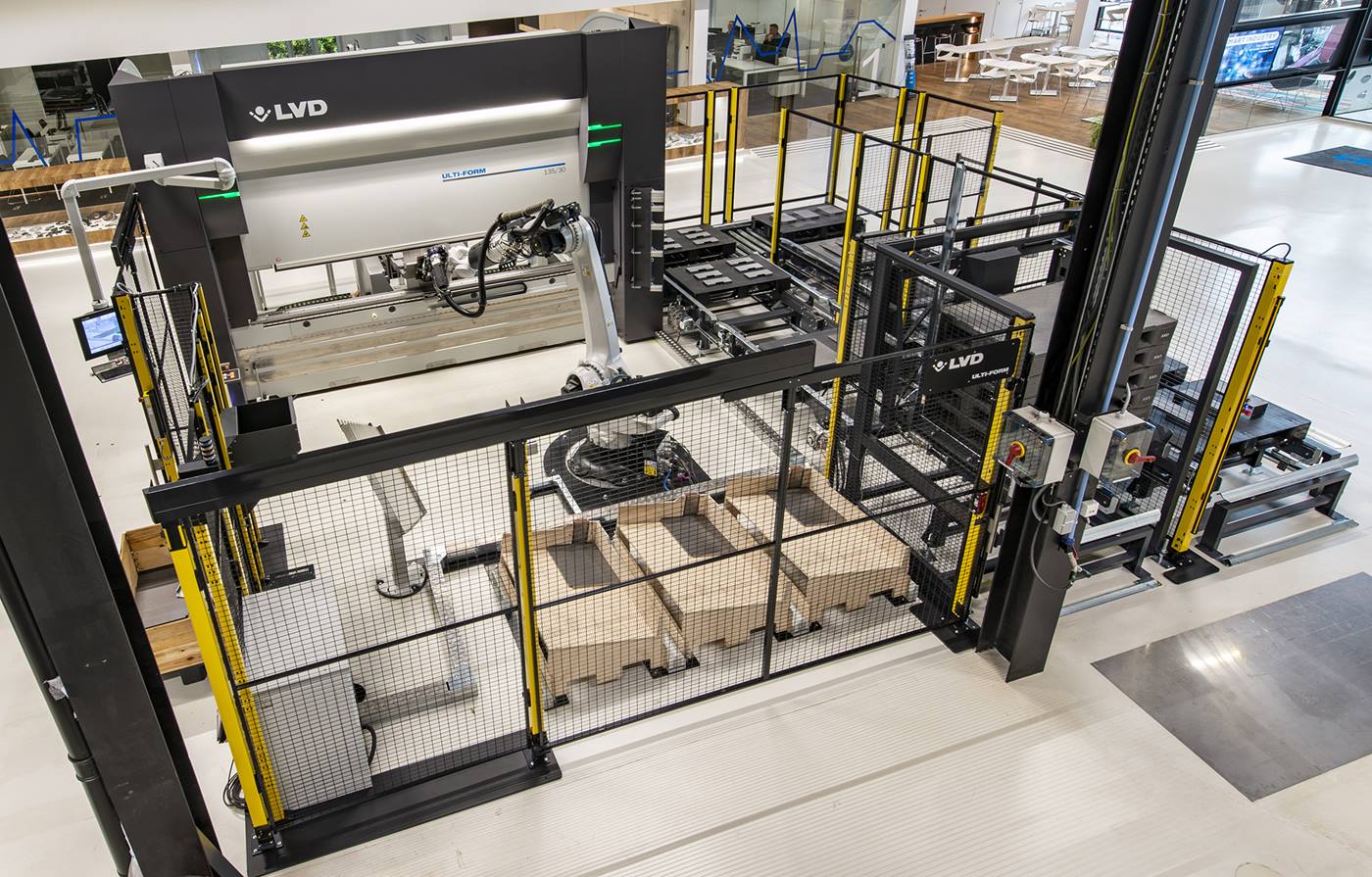

The bending cell for large and complex shapes

The main difference between the Dyna-Cell and Ulti-form is the size of the parts to be bent and the large output area with pallet machine and conveyor system. In the case of the Dyna-Cell, KUKA's CYERBERTECH robot was able to automatically bend parts from 30 mm x 100 mm up to 350 x 500 mm, whereas with the Ulti-Form these are parts from 50 x 100 mm up to 1200 x 800 mm, where long and complex shapes are also possible. For this purpose, the Ulti-Form is equipped with a QUANTEC robotic arm from KUKA.