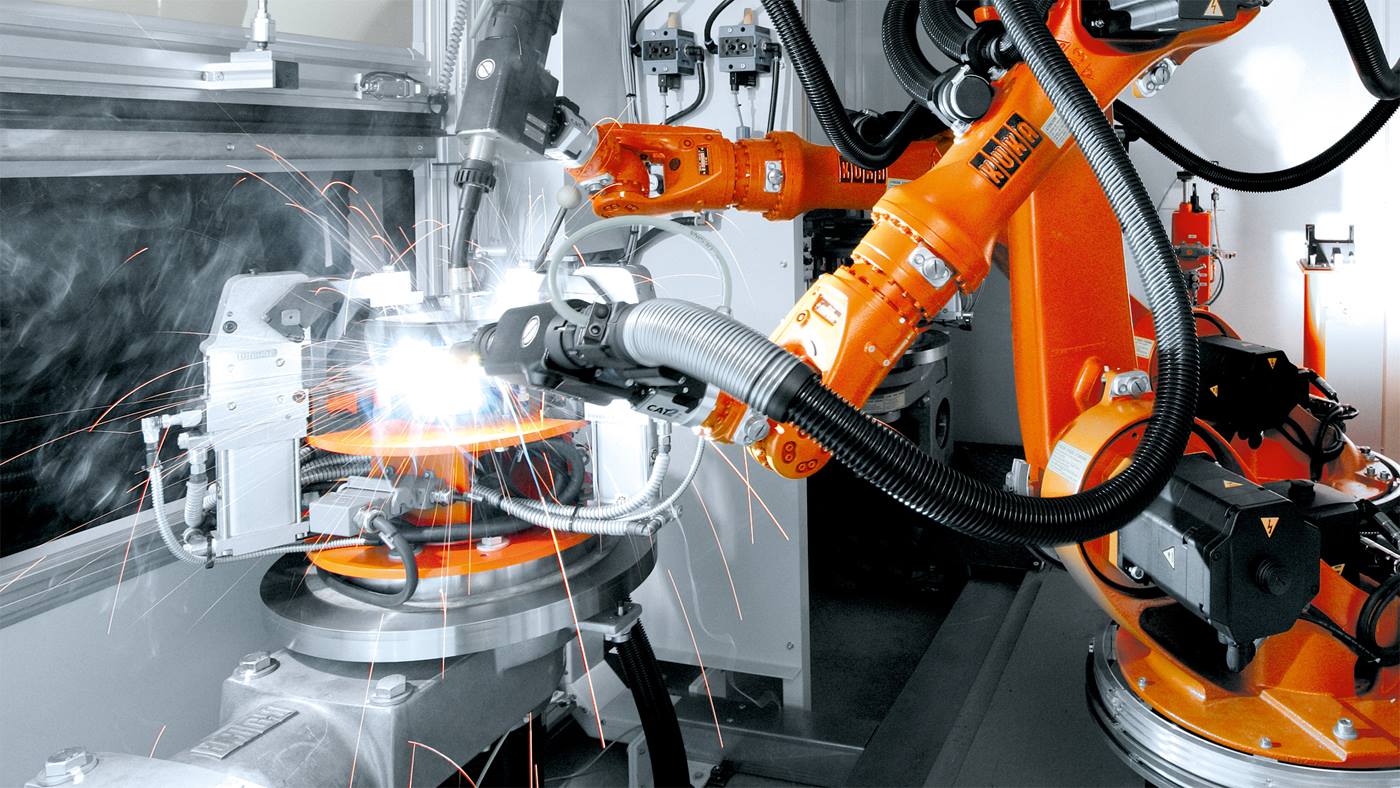

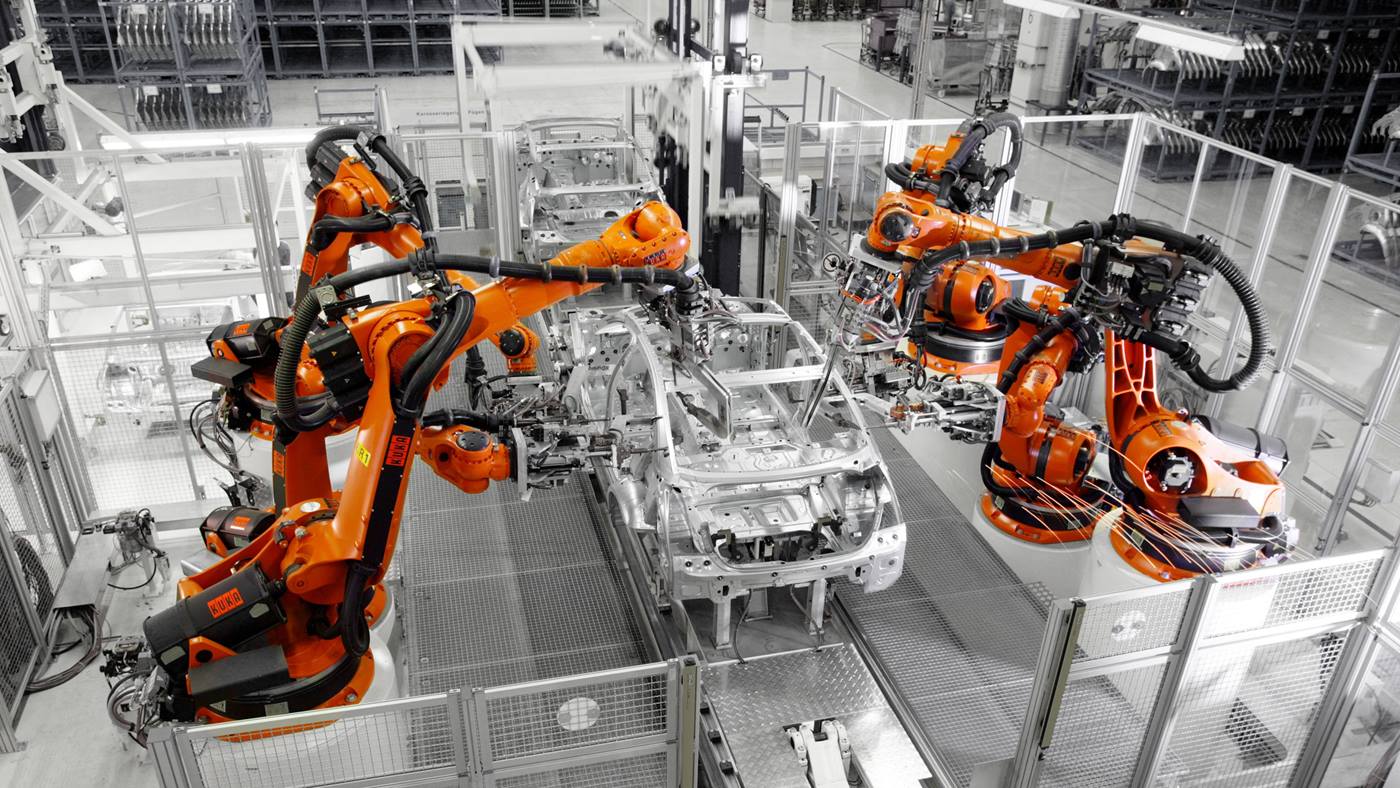

Welding large parts with a KUKA body-in-white line for process stability

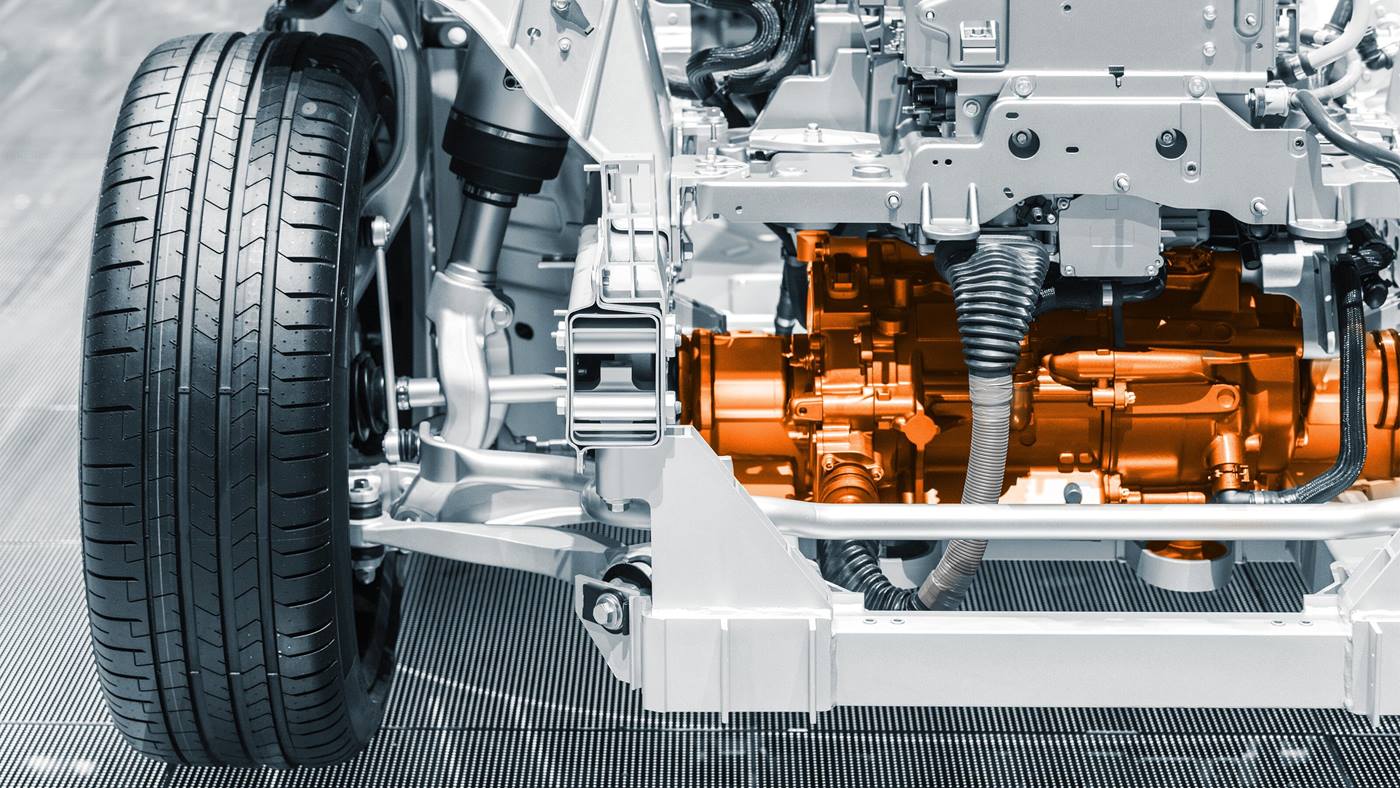

The G-Class has been an integral part of the Mercedes-Benz product portfolio since 1979. The robust and durable off-road vehicle enjoys iconic status. This also remains true of the latest update. The main focus was placed explicitly on the engineering and the recognition value – two features that have characterized the G-Class right from the outset. Particular attention was paid to the reworking of the ladder frame, which provides the required stability of the vehicle body, enabling the vehicle to make its way safely over mud, gravel and rough terrain with its additional 53 millimeters in length and 121 millimeters in width.

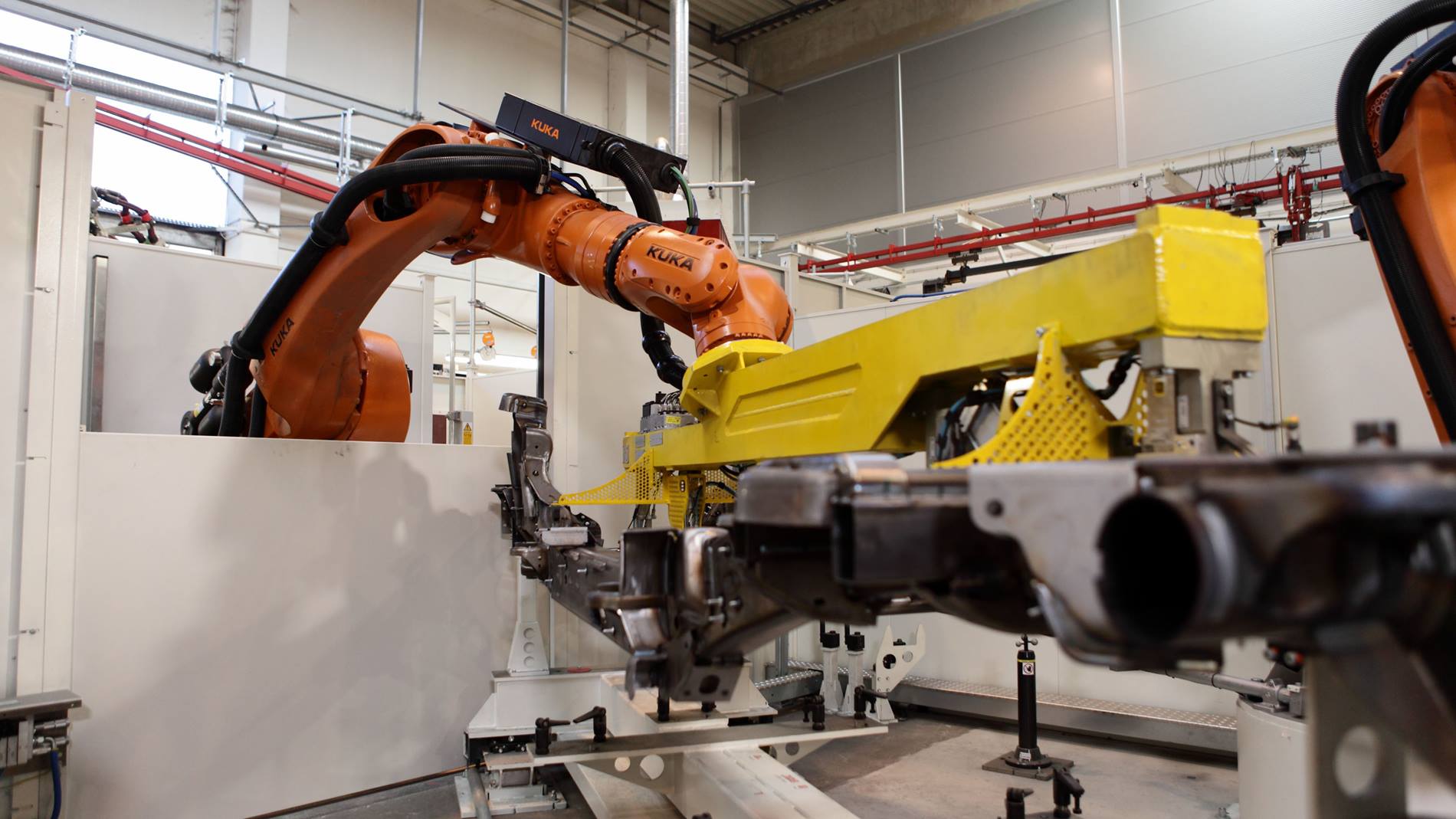

The launch of the new G-Class also marked the beginning of a new era in production: whereas the welding of many large parts had previously still been done manually, this work is now carried out at MAGNA Presstec by a production line from KUKA that can weld the ladder frames automatically.