Flexible and simple: everything is iisy

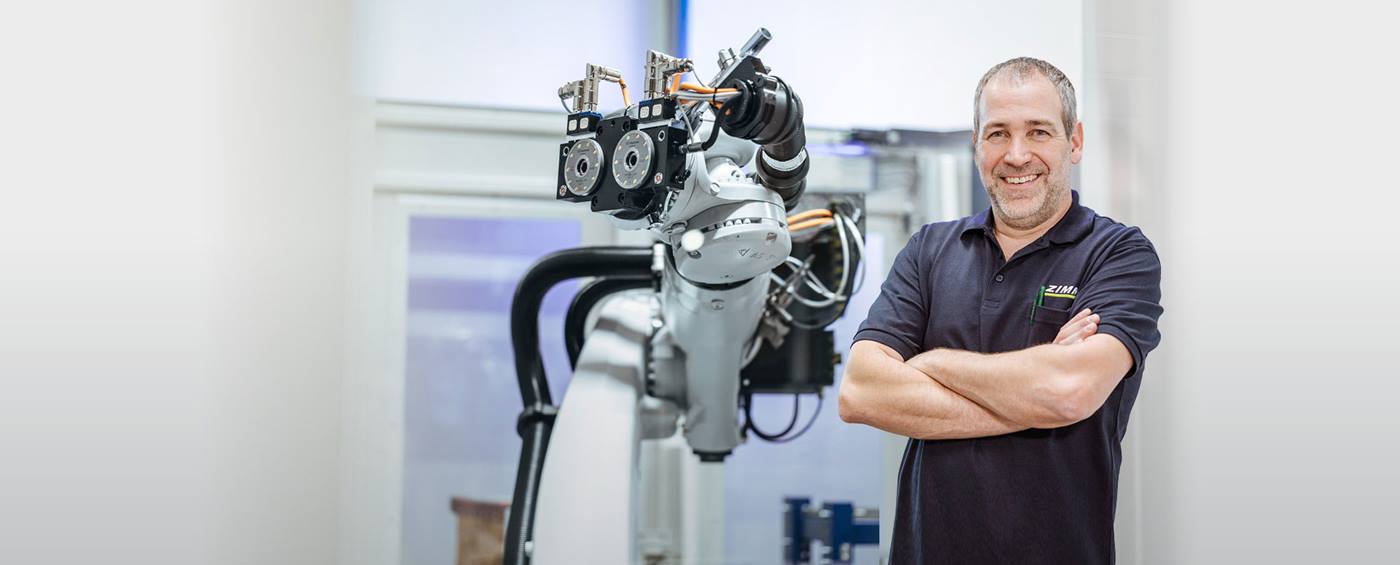

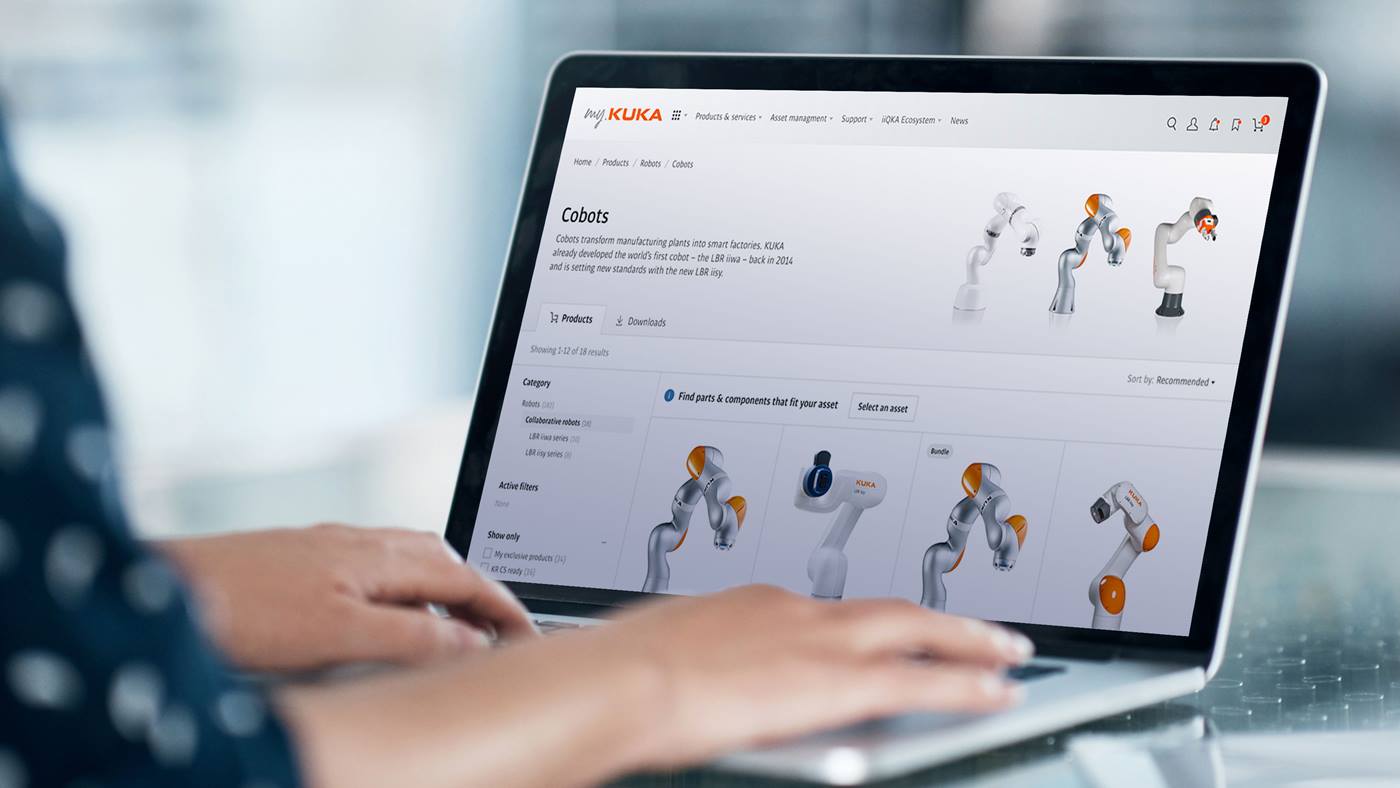

At a recent trade fair in Kassel, Bastian Fest, Managing Director of FMO Surface GmbH & Co. KG, met KUKA sales engineer Robert Korte. Robert introduced Bastian to the LBR iisy collaborative robot who was immediately convinced of the cobot's many advantages. After taking a closer look at the LBR iisy at KUKA’s branch office in Siegen, Fest went away and made the decision to purchase the robot – something he did easily and conveniently via KUKA Marketplace, the online digital customer portal. “The LBR iisy collaborative robot combines several factors that met many of our requirements: its flexibility, its ease of programming, and its suitability for collaborative operation. These are the main reasons we bought it, even without knowing initially where exactly within our quality management system we wanted to use it,” said Fest of this seemingly unusual approach.

When it comes to robot programming, Fest describes himself as an absolute beginner, despite completing a training course at one of KUKA's accredited training colleges when he purchased his very first KUKA robot - a KR CYBERTECH industrial robot, some four years earlier. But this was all the more reason for him to be delighted with this new collaborative robot. The LBR iisy is so easy to use, it provides even novice robot programmers, with little to no previous programming experience, to thrive within robotics, even outside of typical manufacturing scenarios. Furthermore, the cobot ensures safe operation in shared workspaces, with no need for protective fencing.