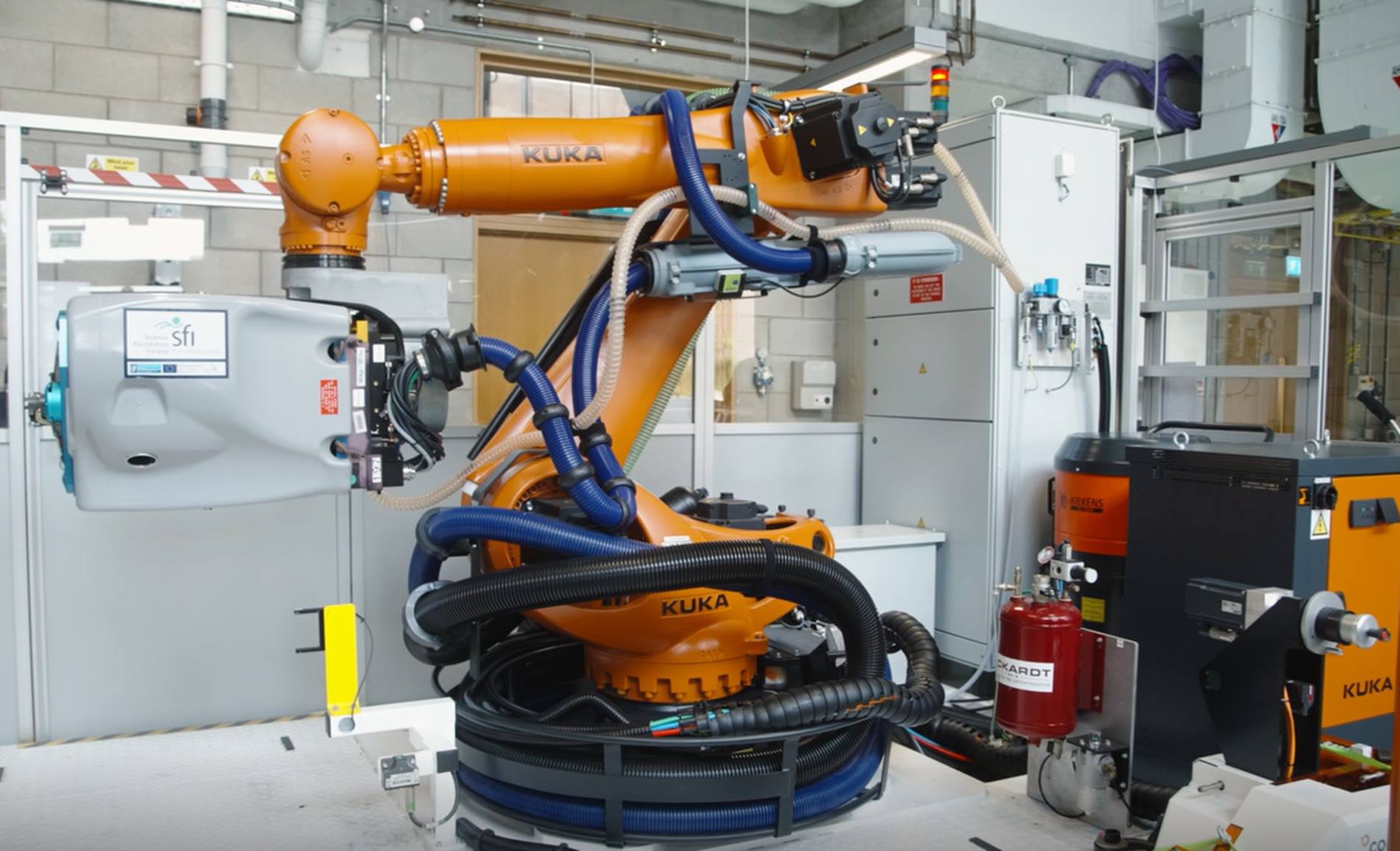

Confirm has nine different Research Performing Organizations (RPO’s) strategically positioned across Ireland, and this particular project being undertaken at Limerick University is funded by sfi. The KUKA advanced robotic joining suite consists of a six-axis KUKA KR210 robot with a seventh axis positioner, or linear track.

Confirm is a smart manufacturing Research Center, which is funded by the Science Foundation Ireland https://www.sfi.ie/ that undertakes research and development initiatives in the areas of Advanced Robotics, Cobotics, Simulations and Modeling. Many projects are delivered in partnership with major Med Tech companies, Pharmaceutical companies and also SME’s.

As part of their research activities, Confirm utilises industry-leading ultrasonic welding equipment, to support their advanced joining development. They are also advancing their latest and greatest safety arc composite materials and as part of their development, there exists the need to understand how these composites can be joined. The KUKA industrial robot within the joining cell is used by Confirm to join composite aircraft materials that could be utilized by major aircraft manufacturers.

Eoin Hinchy, Lecturer in Digital Manufacturing and Automation at the University of Limerick said of the joining suite: “KUKA France developed the advanced, multi-function end of arm tooling that is used within the cell, which enables the efficient application of drilling and fastening. It also has an integral vision system, developed by KUKA Aerospace, France. The whole project offering in terms of the KUKA robot and the multi-functional end-of-arm-tooling is something that was very valuable to Confirm, and that's why we partnered with KUKA on this project”.

Brian Cooney, Managing Director, KUKA Ireland added: “KUKA are very much a company that is at the leading edge of the digital transformation, and because we're leading in that area and those technologies, research centres such as Confirm can take our learning, can join with us and can work with us on taking some of those learnings and applying them to the research that they're undertaking on-site in Limerick”.