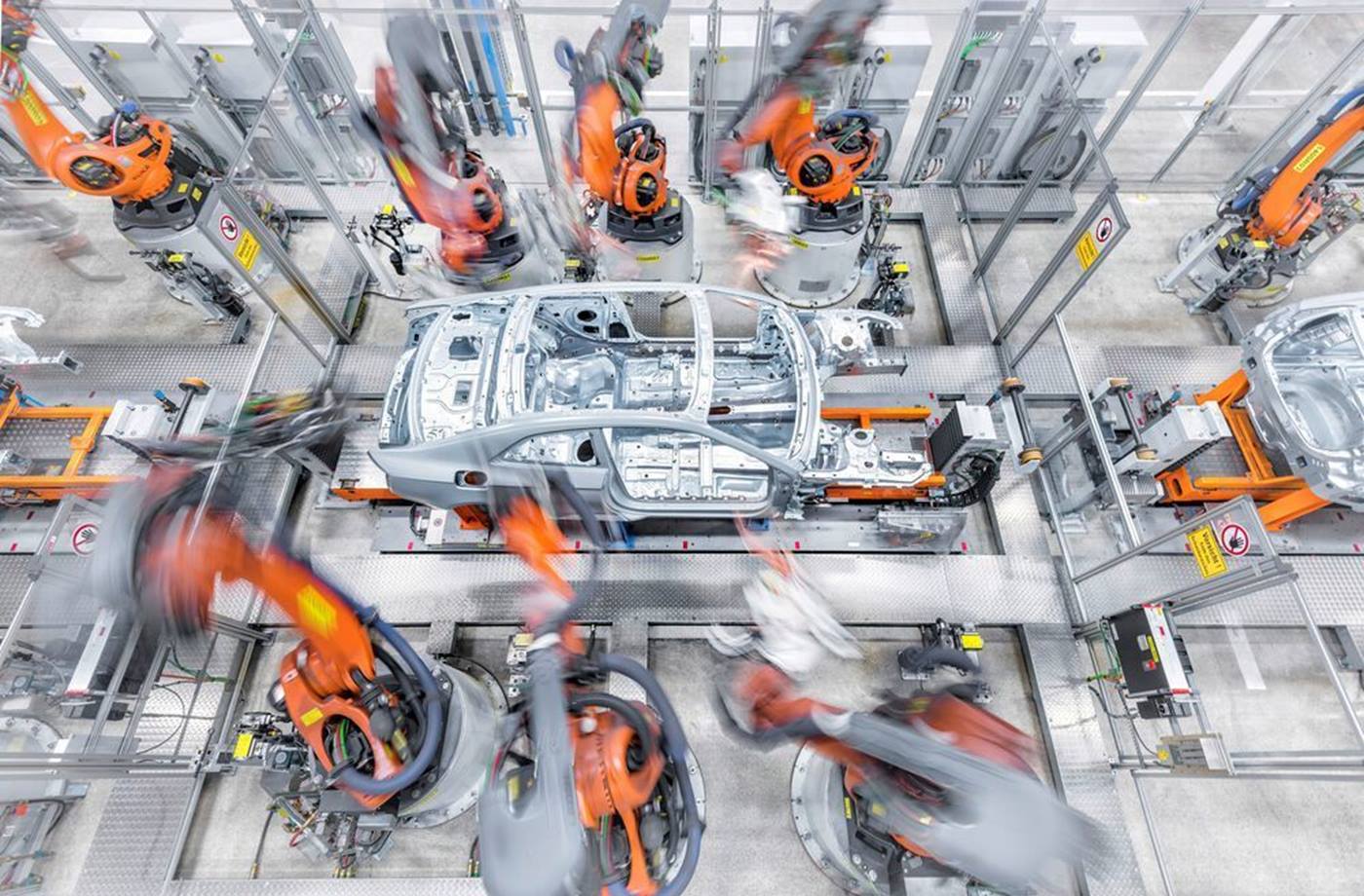

We teach your KUKA robot to see and feel

Robots with integrated sensors and with real-time control – thanks to fast data exchange between the sensor and the controller, robots are able to react to changes in the environment and even determine the motion path during the motion itself. This enables applications that go far beyond simple handling tasks.

KUKA supports you in the development and implementation of highly flexible automation solutions that are one step ahead of the competition. Increase the flexibility and precision of your robot automation with know-how directly from the manufacturer.

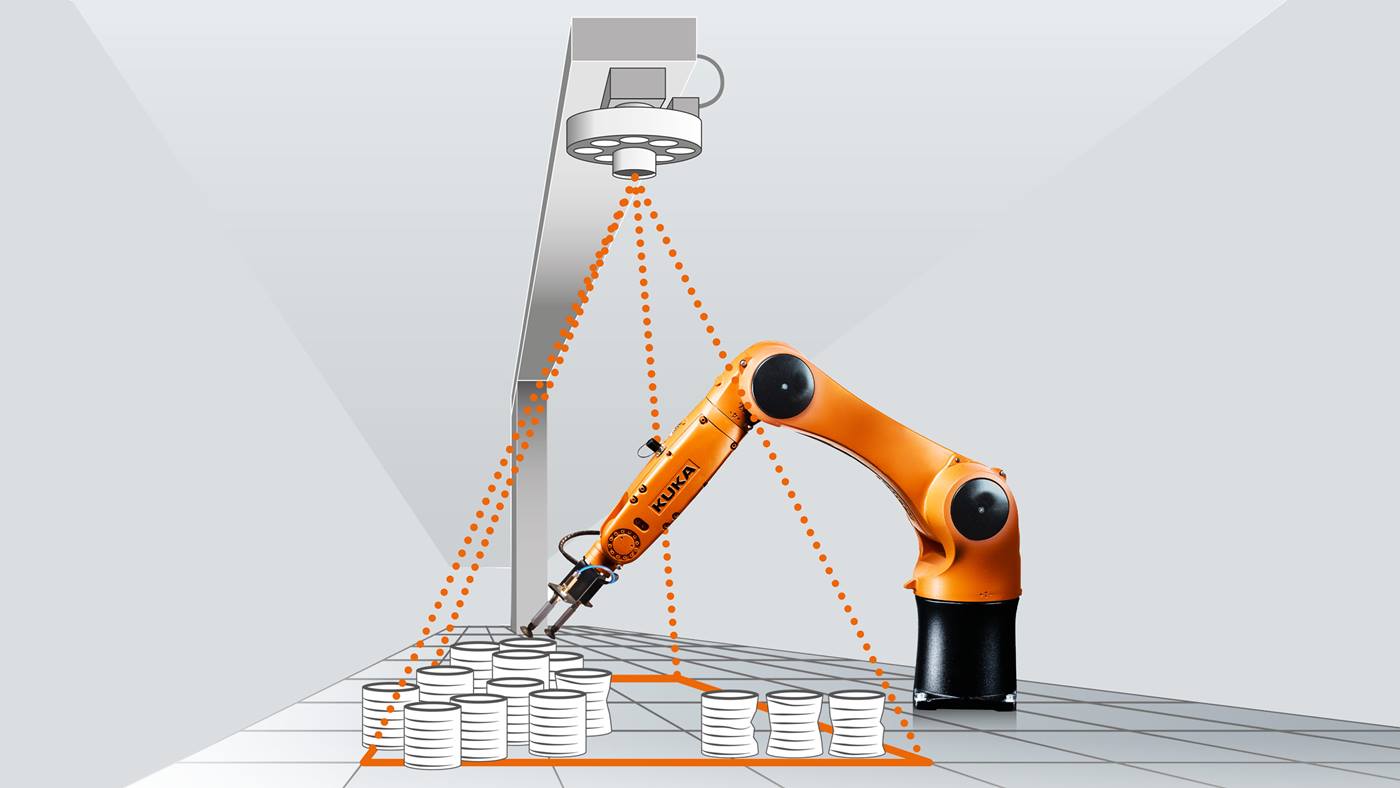

Software for industrial image processing

Would you like to have your robot guided by a camera system or do you want to inspect or measure your components? KUKA offers solutions for the entire spectrum of industrial image processing – from quality control and 2D pick & place to complex bin-picking tasks.

In addition to KUKA technologies, we also connect third-party sensors and camera systems to your deployed system via customized interfaces.

Force/torque sensor systems for KUKA industrial robots

Do you work with sensitive components or require defined joining forces? We teach your robot sensitivity! We offer hardware and software services from a single source to provide solutions for your sensitive joining applications – from haptics tests to force-controlled material processing tasks. We support you in connecting the force/torque sensor system you provide to your KUKA robot through the use of the KUKA.ForceTorqueControl software.

We also connect various measurement sensor systems, such as distance sensors, to your KUKA controller for you via the KUKA.RobotSensorInterface software. Beyond this, our expert staff support you in programming your real-time control application and provide you with valuable advice on optimally implementing your automation task using force/torque sensor systems.