Planning

Consultancy during conceptual design

In the conceptual design phase, you can already benefit from the support of our application specialists, whose longstanding and broad experience will help you to avoid planning errors at an early stage.

You are using Internet Explorer and will not be able to use our website properly.

Please change to an up-to-date browser for ideal presentation of the website.

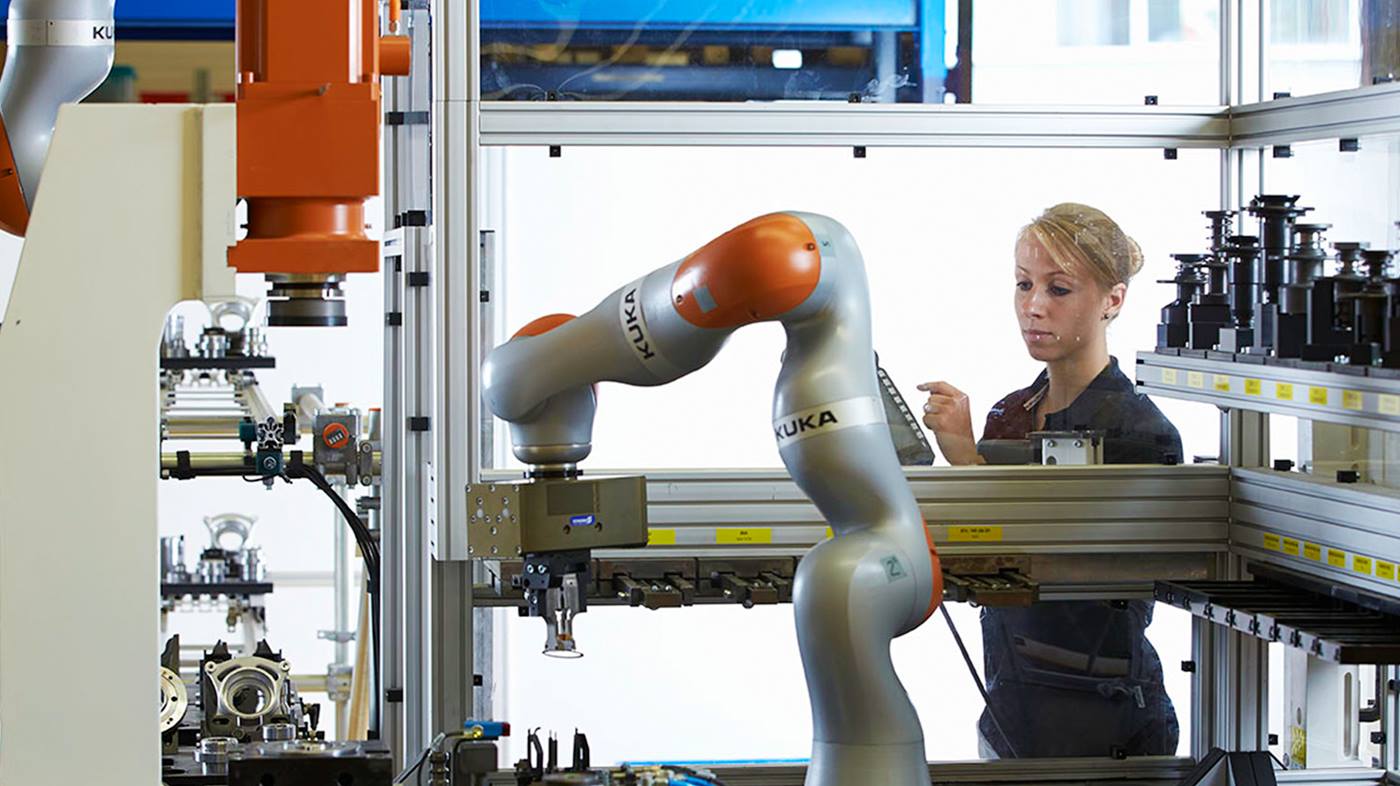

With the aid of our support services, applications and robots can be programmed without interruptions in production. We support you in preparing for product changeovers and commissioning offline as well as responding quickly and flexibly to changes in the production process.

In the conceptual design phase, you can already benefit from the support of our application specialists, whose longstanding and broad experience will help you to avoid planning errors at an early stage.

The ideal combination to optimize cycle time when implementing your application. The simulation helps to determine the optimal motion paths and pick-up points. The results of the simulation are used in offline programming to ensure quick and cost-efficient implementation of the application on your system.

Safety is increasingly implemented through software products. We offer advice during the planning stage of your safety concept and later on when configuring the KUKA.SafeOperation technology packages. Additionally, we would be pleased to offer customized workshops regarding the Machinery Directive.

Find out more about KUKA safety services.

Standardized and structured robot programming lowers maintenance costs and reduces downtimes during troubleshooting. Program adaptations or expansions can be carried out more quickly. We offer you ready-made program modules and flexible control concepts for the robot. The appropriate PLC interface is included in the package.

Our experienced application specialists evaluate in advance how you can optimally implement your ideas with the support of our products.

We carry out the complete robot programming for your production system – both for KUKA robots with a KR C4 and for the LBR iiwa with a Sunrise controller. In close cooperation with you, we optimize the process sequences and support you with the integration of robots into your production system.

Our range of services also includes programming your system controller via the Totally Integrated Portal (TIA Portal) from Siemens. This enables robots to be integrated into your system controller in no time at all.

You require support with the programming of your application for a limited amount of time only? You want to expand your current spectrum of components? Our specialists can turn your specifications into structured and logically designed programs. You can request our support on a daily or weekly basis according to your needs.

We configure the KUKA.SafeOperation technology packages according to your specifications. We then check and document the configuration, starting with the cell area, the workspaces and protected spaces, and including the various tools and reduced velocities. On request, we test the space limits of the robot including its stopping distances.

You would like to expand your production process with new functions? You want to adapt the communication signals to the robot because your new machine tool offers greater capabilities?

Functional expansions are another element in our range of services, allowing you to adapt your current system to new requirements.

We offer customized workshops on the topics of programming, program standardization, machine safety and SafeOperation. The workshops can be carried out either at KUKA or directly on site. The focal points of the workshops are geared to your individual needs.

Tune my Production helps us discover the optimization potential existing in your current production system. We examine your system on site and suggest possible means of improving productivity, process quality and usability.

You would like to modernize your production system and trade in your previous robot for a current, state-of-the-art product? We are happy to support you in carrying out the exchange with a service package customized to your requirements. Starting with removal and installation of the robot, encompassing adaptation designs and program conversion, and extending up to commissioning, support with production start-up and instruction of your system operators.