Developing the Workforce of Tomorrow

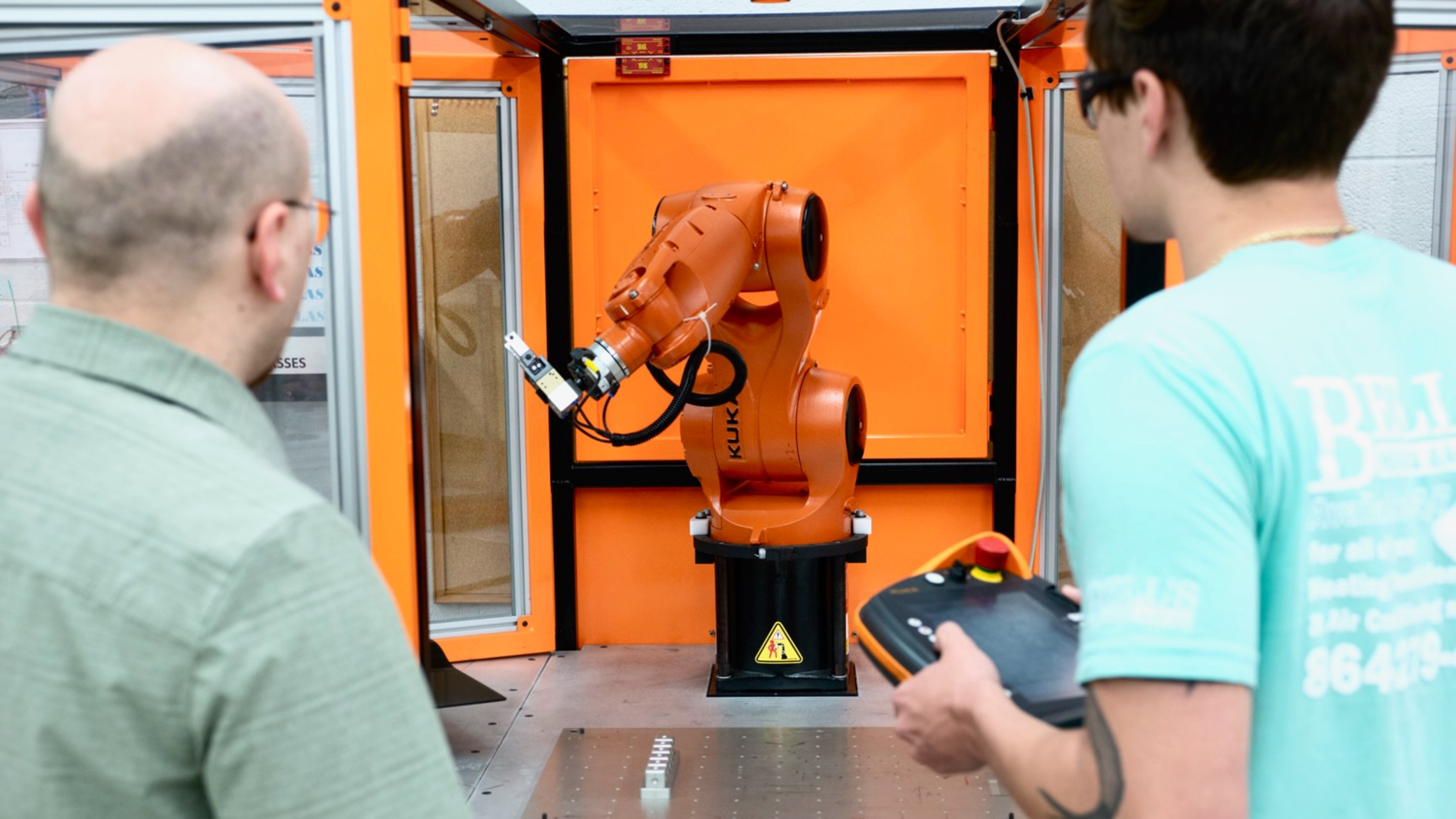

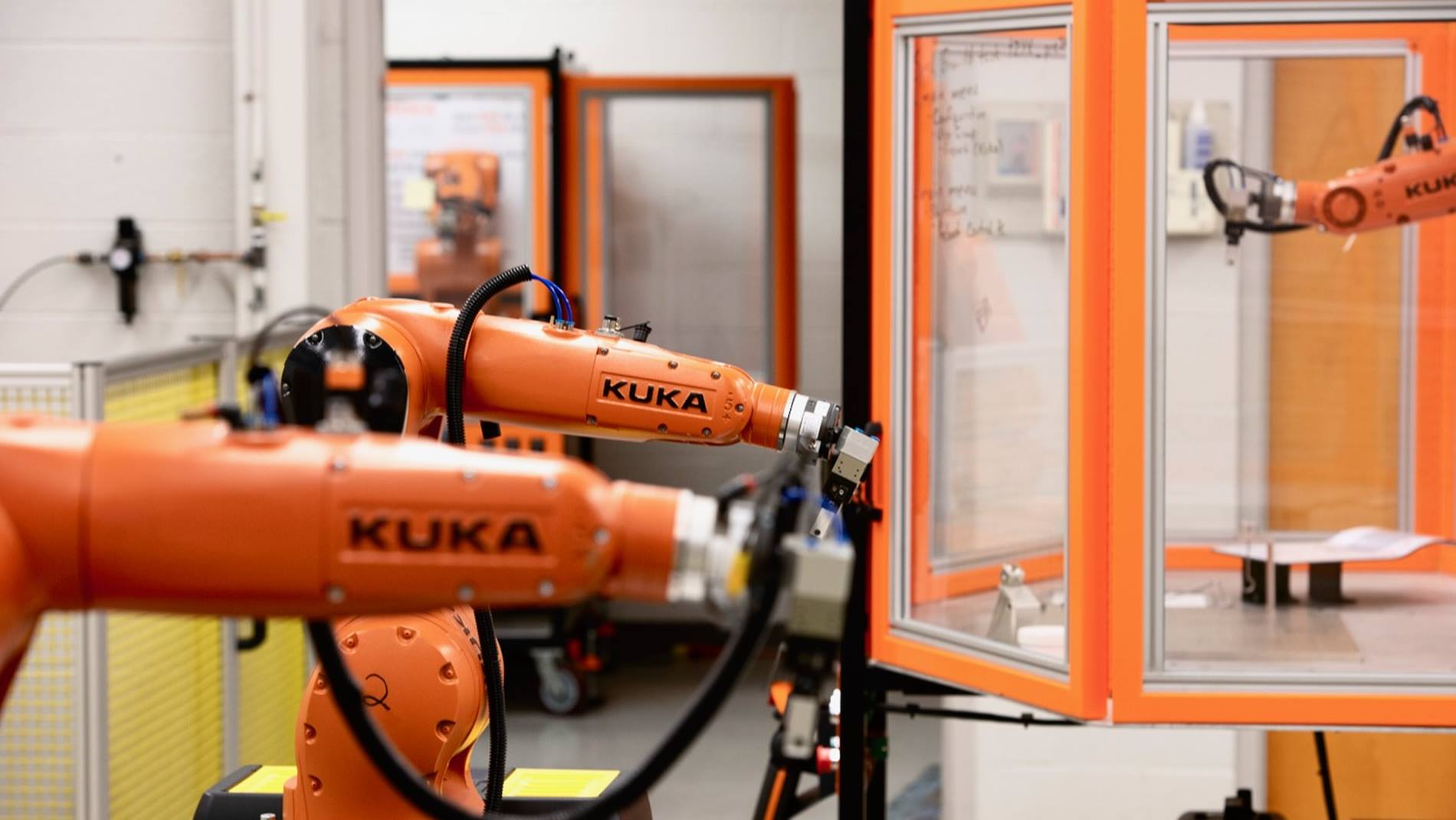

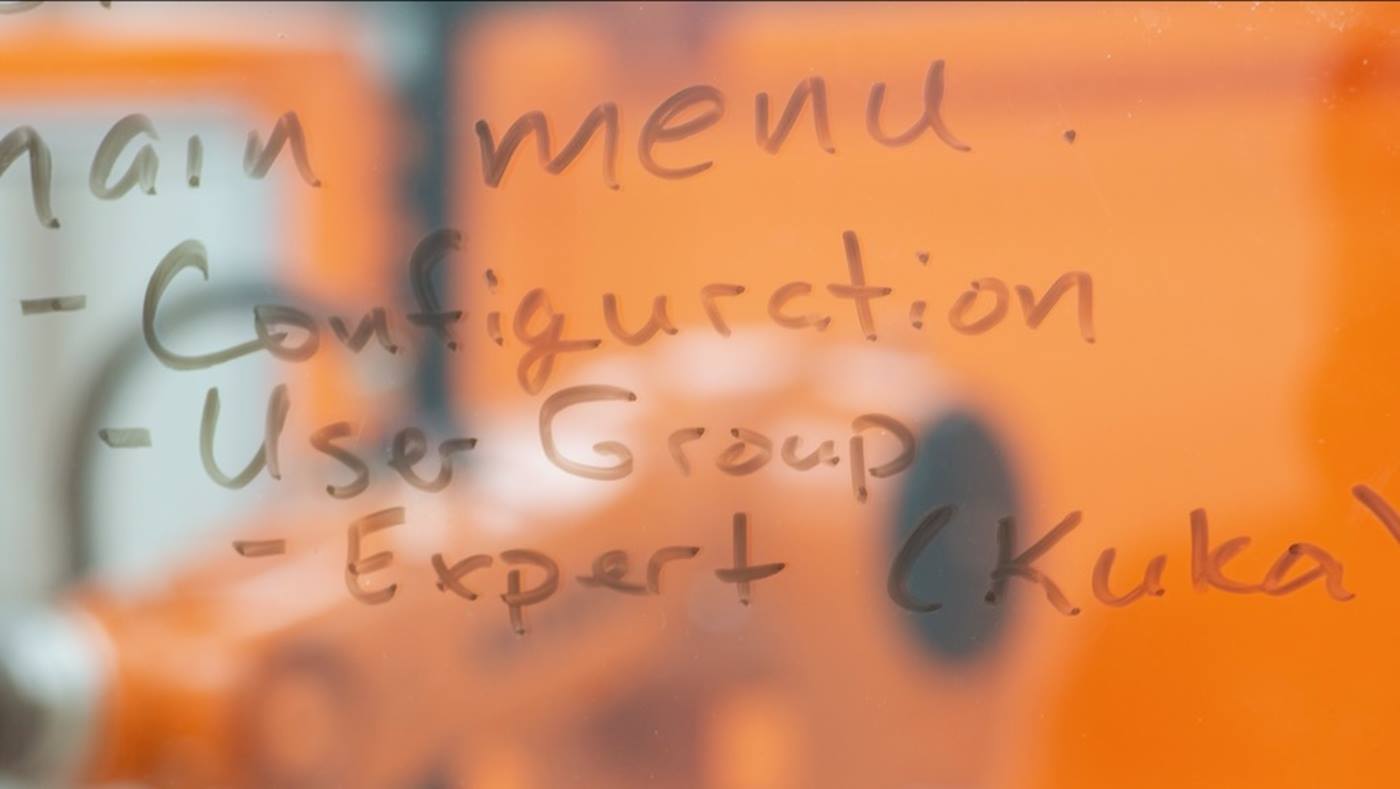

It is for this reason Spartanburg Community College (SCC), with five campuses in three counties in upstate South Carolina, has provided technical education to the region’s citizens for more than 60 years. Its diploma, certificate and degree courses evolve continually to enable graduates to meet the current needs of local industry. The school also conducts frequent job fairs for prospective students resulting in some manufacturers recruiting students and paying them to get technical training at SCC while also receiving on-the-job training at the manufacturer’s facility.