Automation Enables 24/7 Production of Precision Parts

Waybo provides an automated machine tending solution for machine shop's low-volume, high-mix production strategy. The automation enables the 24/7 production of precision parts, significantly enhancing machine shop PRÉCINOV's sales.

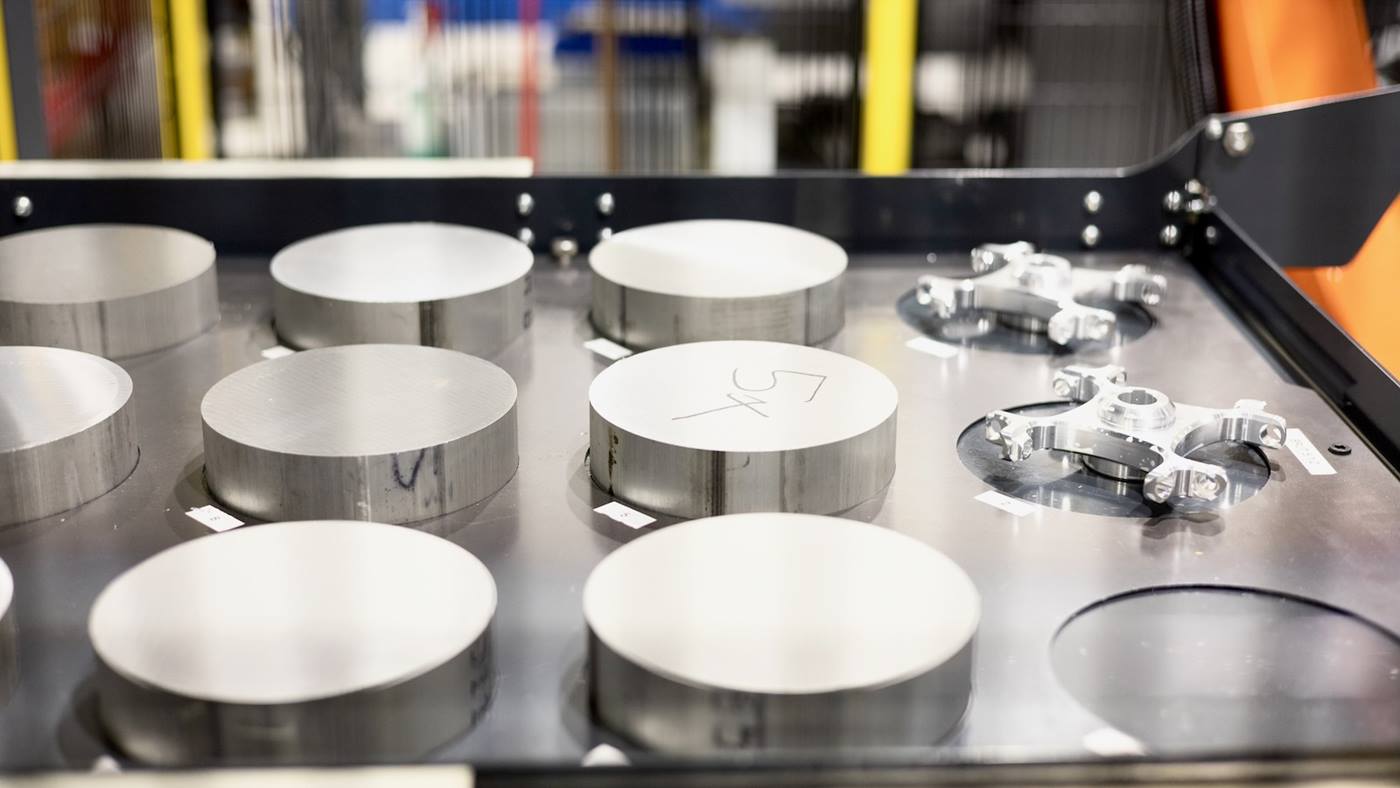

PRÉCINOV specializes in the manufacturing of small, complex high precision parts, mainly for high technology customers in the opto-mechanics, robotics, medical, electronics, and energy industries.

Precision production 24/7

Citing the ongoing shortage of experienced shop personnel, DeBlois said, “We don’t want to waste our skilled individuals using them to load and unload a machine. We need their brains for setting up machines.”

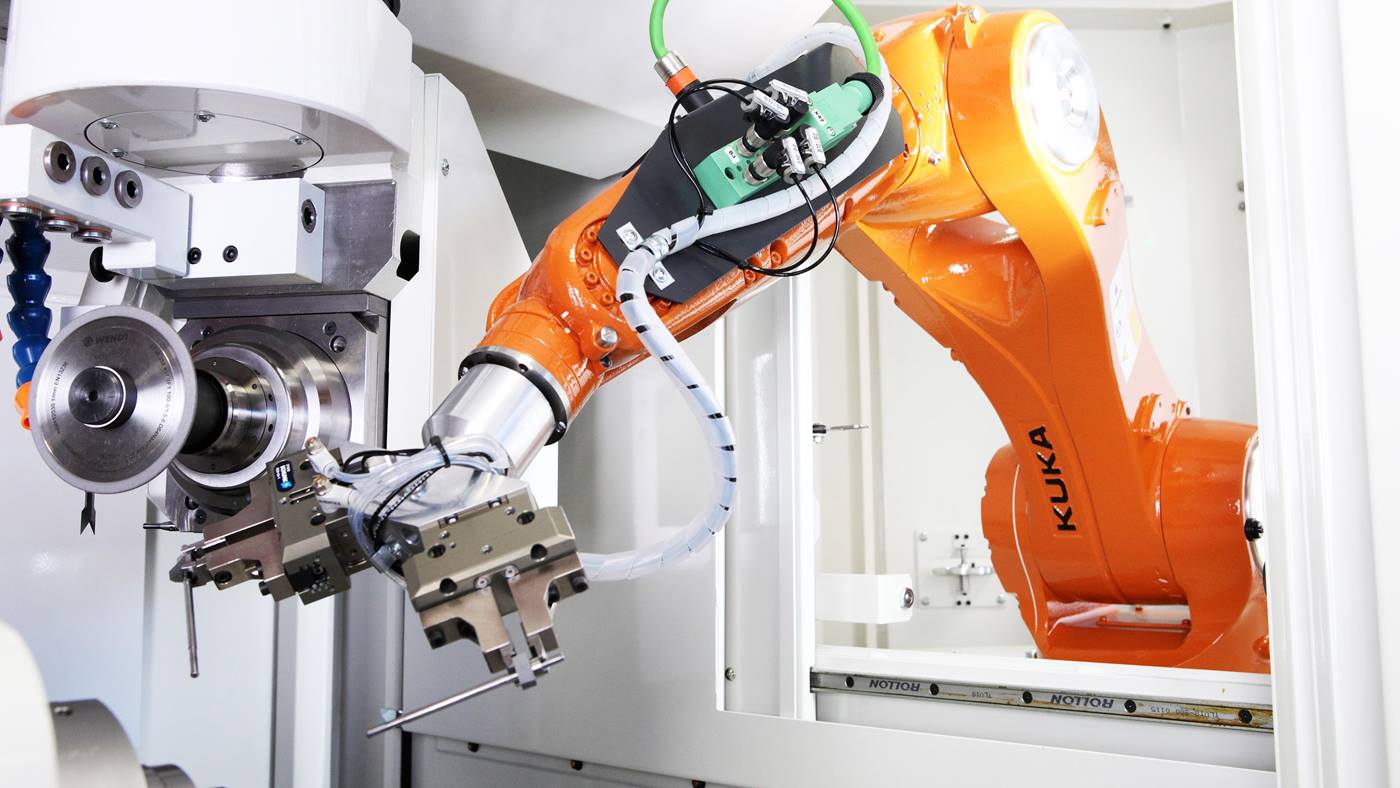

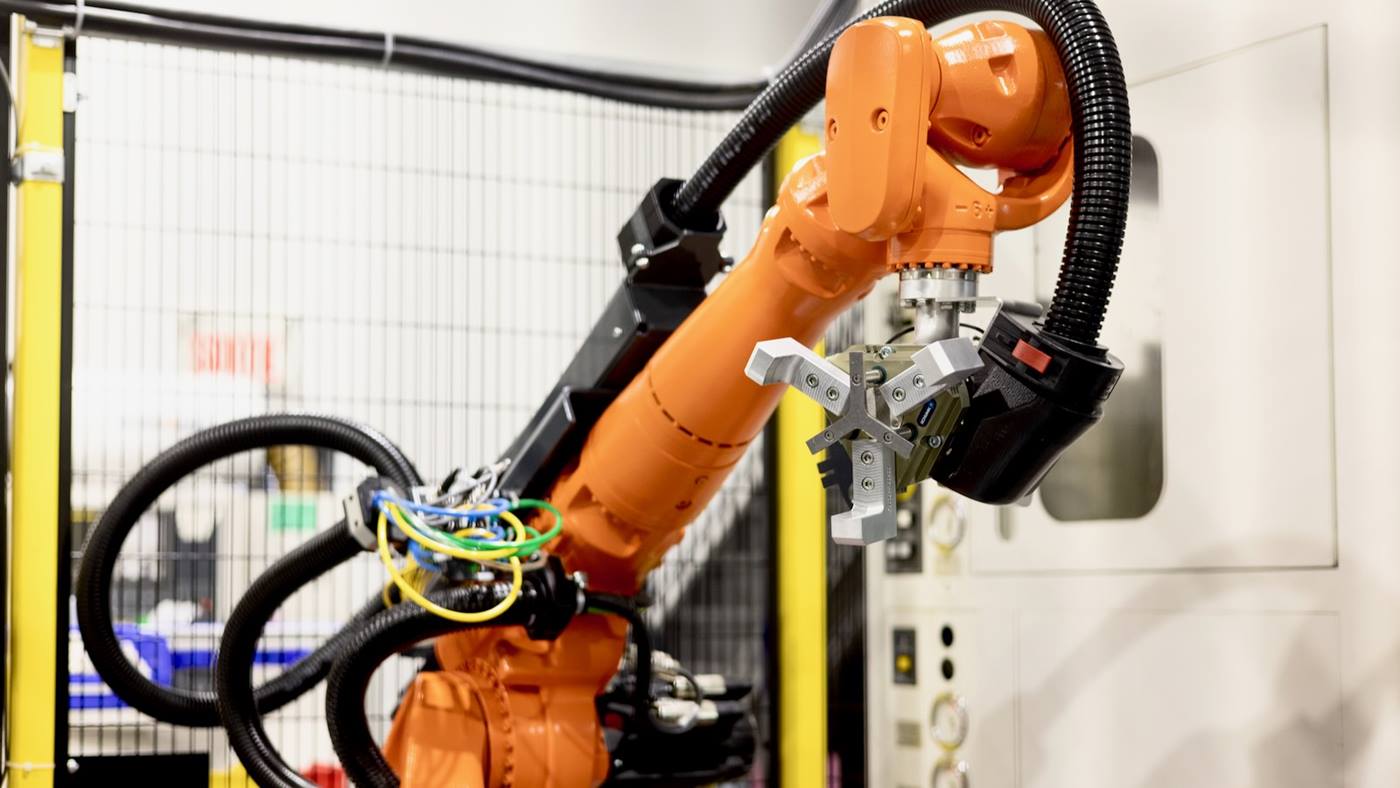

PRÉCINOV’s Waybo machine-tending cells incorporate KUKA robots.

The shop has five KUKA robots, including three KR AGILUS units with 10 kg maximum payload capacity, a KR CYBERTECH robot with 23.9 kg maximum payload and 1813 mm reach, and a KR CYBERTECH with up to 27.3 kg maximum payload and 1612 mm reach. The six-axis AGILUS robots are designed for high working speeds and precision. CYBERTECH robots feature outstanding power density and a large range of models.

Flipping a part has to be accurate to maintain tolerances, and the KUKA robots are very precise.

Accuracy is pivotal

By using a robot on each machine, it is easier for planning, and PRÉCINOV can run whatever it wants, quickly. The shop employs 25 people, and the Waybo automation enables seven operators to keep the shop’s 12 machines working 24/7.

High mix requires ease of setup

KUKA robots are “easy to understand and program,” DeBlois added. “The robot does not add to setup time; the longest part of the setup is not the robot, it’s the CNC machine.” To further expedite programming, the robots extract information from the shop’s CAM programming system regarding part sizes, vises, fixtures or other obstructions in the machine.

The most important advantage of using multiple robots is ease of setup and ability to respond quickly to changing customer demands. Using the same robots throughout the shop simplifies employee training and shifting staff from machine to machine.

More about the KUKA partner