HRC solution makes work easier for quality assurance employees

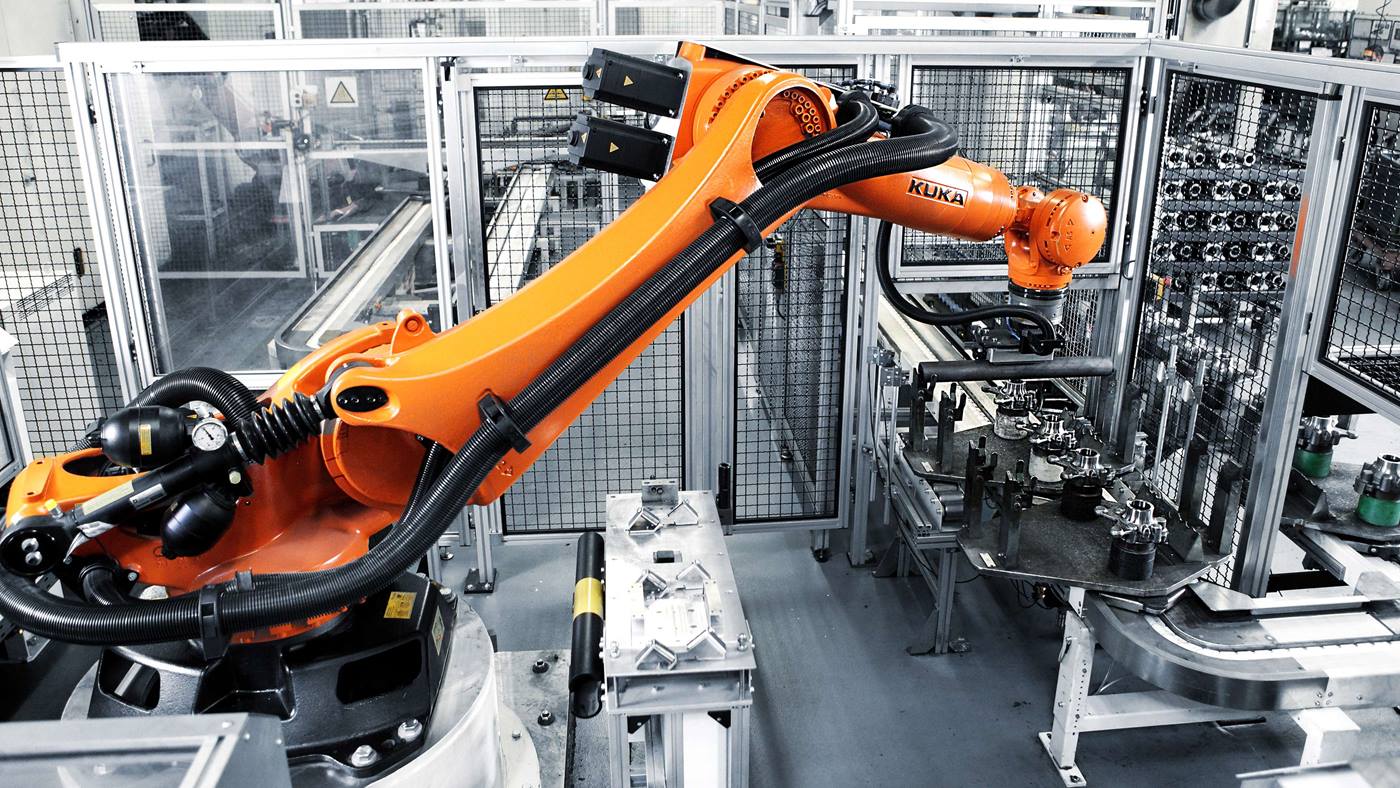

MRK-Systeme GmbH specializes in industrial solutions for human-robot collaboration. The company has developed an HRC-capable automation solution with KUKA robots of the KR QUANTEC series for carrying out quality assurance on crankshaft housings at the BMW Group.

The BMW Group plant in Landshut operates one of the world’s most advanced foundries for light alloys. Crankshaft housings for all models of the BMW fleet are manufactured here – for three, four and six-cylinder engines. Quality assurance of the crankshaft housings cannot be fully automated, as these tasks still require the trained eye of the employees. For this reason, BMW opted for a system in which humans and robots directly collaborate. The company MRK-Systeme was tasked with the implementation. “Human-robot collaboration ensures that BMW employees are relieved of unergonomic tasks,” explains Michael Mohre, responsible for the Operations division at MRK-Systeme GmbH. For over a year and a half, two identical applications, each featuring a KUKA KR 210 R2900 prime K shelf-mounted robot from the KR QUANTEC series, have been operating on the production line in Landshut. At each station, an employee controls the robot motions with a joystick in order to check the components for defects, all the while maintaining a comfortable posture.

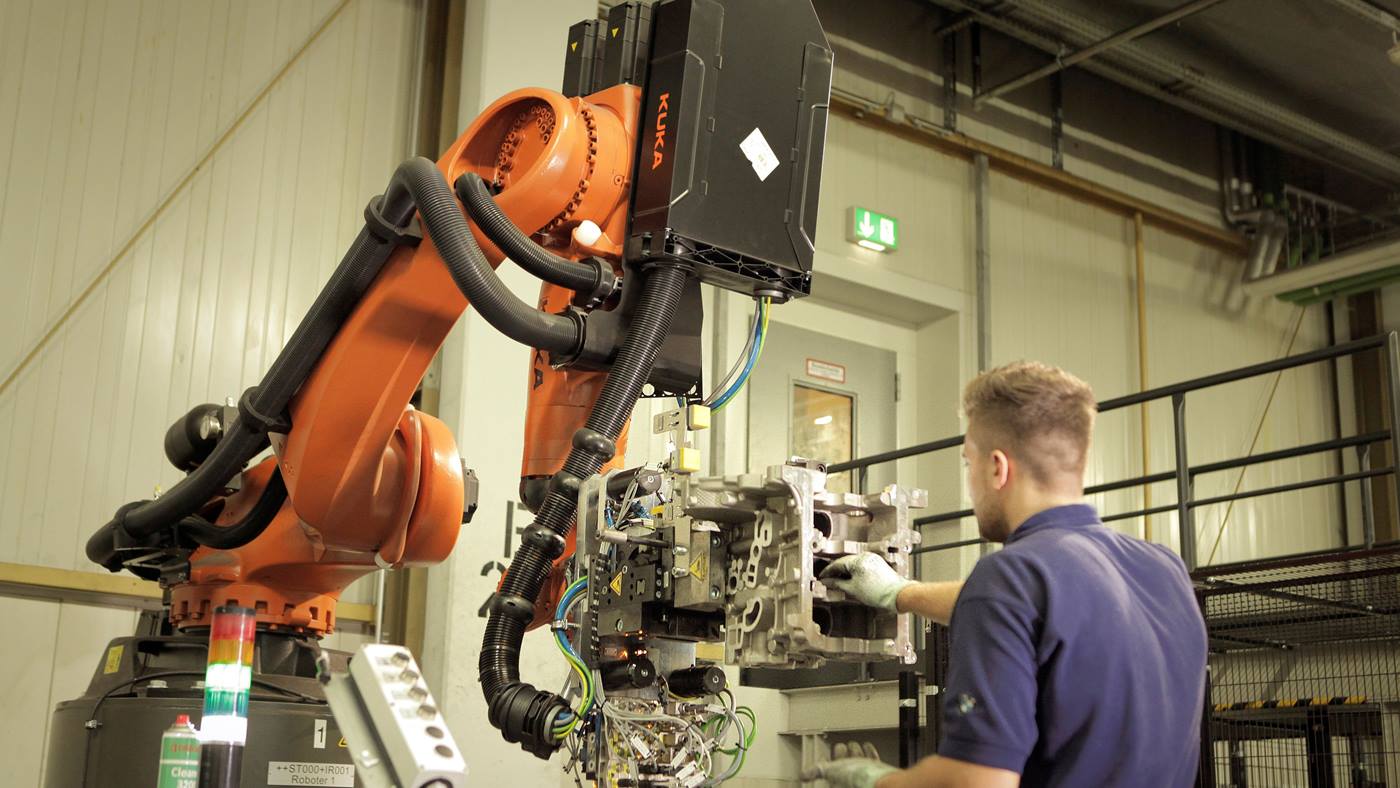

Inspection process supported by robotic handling

A conveyor delivers all the manufactured crankshaft housings to the workspace. Depending on the model concerned, the higher-level robot controller selects the appropriate program for controlling the robot motion. The operator uses a joystick to control the robot’s movements. The robot moves to the housing along a defined path, closes the gripper and brings the component to the operator, who inspects the crankshaft housing for defects using a cold light lamp. During this procedure, the robot securely holds the component weighing roughly 30 kg at the optimum height for the employee. Once the operator has completed the inspection process, he moves the robot with the housing back to the conveyor and sets the housing down. The interactive inspection process is completed by pressing a button. In doing so, the employee documents whether the part is “OK” or “not OK”.

The feedback has been resoundingly positive. Cycle times can be maintained and the work is much more comfortable for the employees.

Expansion of the existing system planned

Both systems have been operating successfully since 2015. In the meantime, Mohre and his colleagues have been working on an expansion of the system. Two additional test stands for quality assurance are to be installed in the future.