The skills shortage challenges employers: On the one hand, they must ensure high employee satisfaction in order to retain the permanent staff. On the other hand, companies often cannot continue to grow if they lack the employees they would need to do so. This is where automation with KUKA robots offers great opportunities for SMEs. While the robot takes on monotonous, physically demanding tasks, the team can devote itself to more demanding assignments. In this way, employers increase productivity and suit employees by giving them more freedom for more complex activities.

Successful cooperation: humans and robots check codes together

At FMO Surface in Lemgo, around seven million plastic bus connectors are lasered with DataMatrix codes (DMC) every year. In times of a shortage of skilled workers, that's quite a lot. For Managing Director Bastian Fest, the solution was therefore obvious: automation.

What was previously scanned exclusively by employees is now processed jointly by a human and the collaborative robot LBR iisy. Equipped with two cameras, the robot checks the DataMatrix codes. For this purpose, 200 plastic parts slide under the robot on a tray. “The first step spot checks the quality of the codes on the basis of 20 parts,” explains foreman Tim Hertz. “If everything is OK, the cobot moves over the tray again to check whether all 200 parts are present and all codes are readable.”

If something is wrong, i.e., if a code is of poor quality or incomplete, the robot stops and points out the affected bus connector. A human colleague can then replace the faulty part, the robot checks the tray again and ideally releases it. This human-robot collaboration ensures maximum safety and efficiency. “The LBR iisy saves us an enormous amount of time because we no longer have to scan each part individually,” Hertz summarizes.

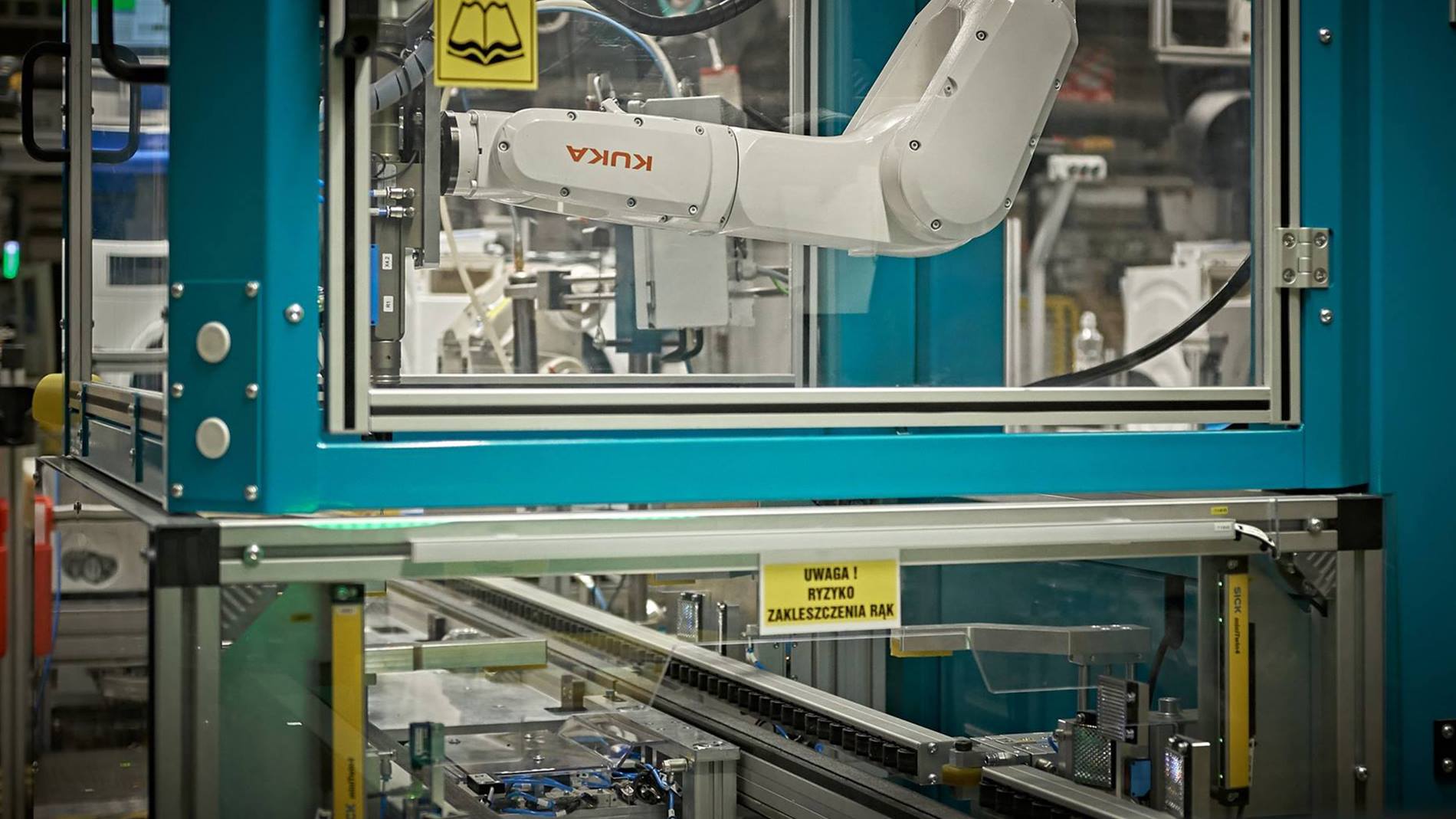

Industrial assembly: Robot screws in flow operation

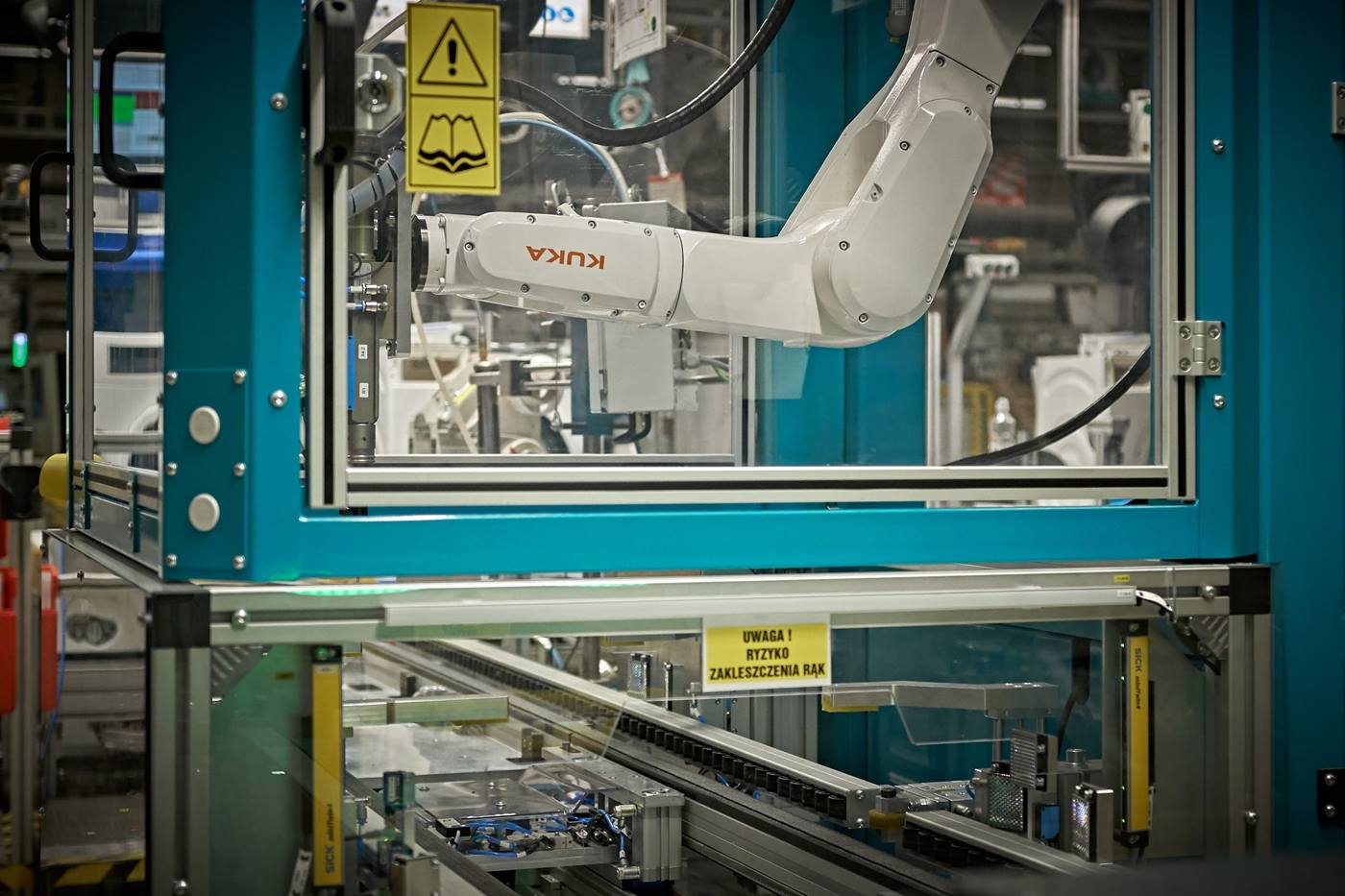

Qbig engineers specialize in increasing the productivity of industrial plants. The developers from Lodz recently boosted the productivity of a major household appliance manufacturer: They integrated the KR AGILUS into an assembly line, where it now screws the porthole windows into the washing machine doors. The robot screws in continuous flow operation, i.e., it assembles the components while they are moving along the conveyor system. The cooperation between the robot and the conveyor is synchronized by the software KUKA.ConveyorTech. “By using robots, we were able to shorten cycle times and thus increase productivity,” reports Bartosz Luczak, co-owner of Qbig.

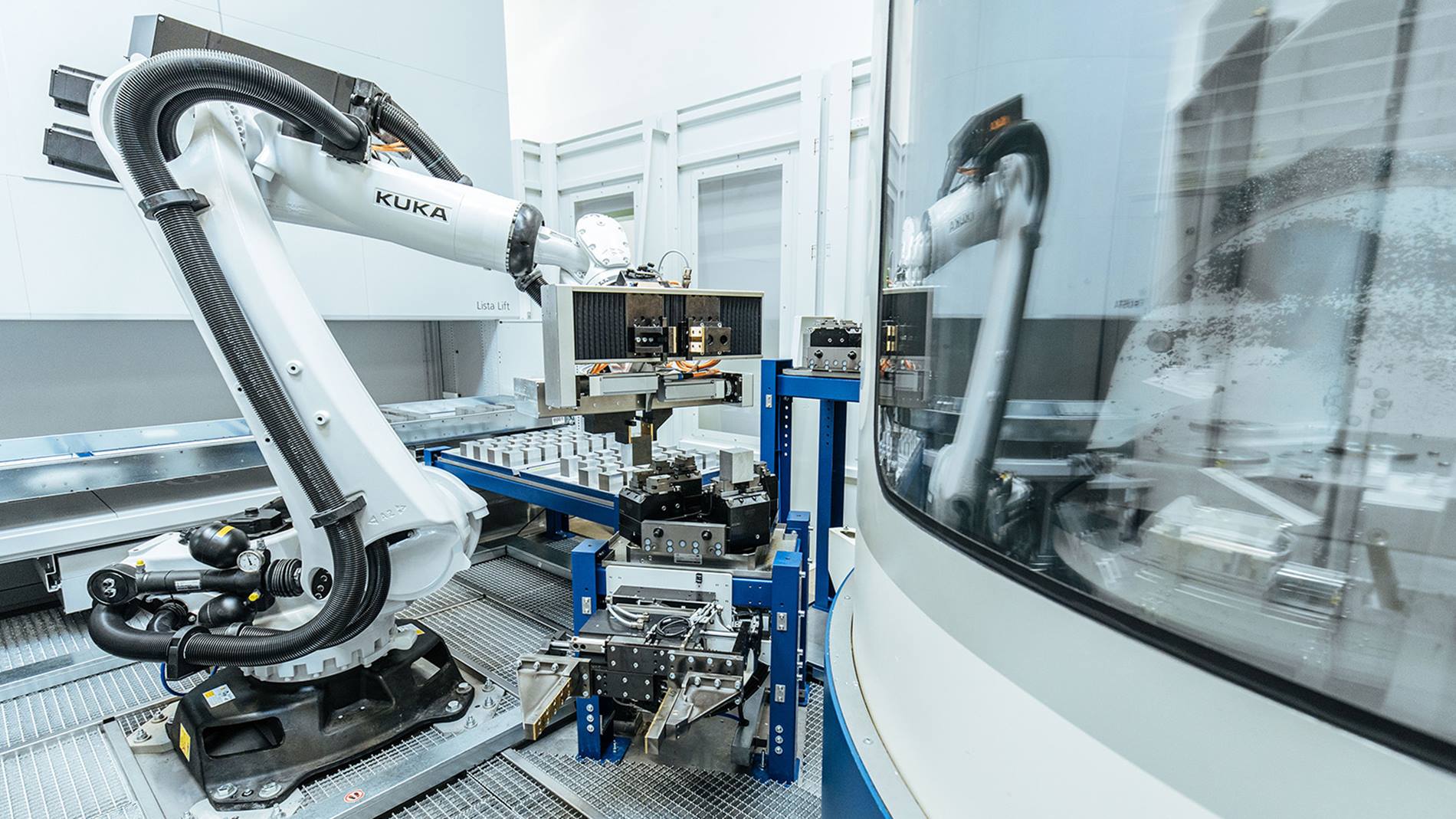

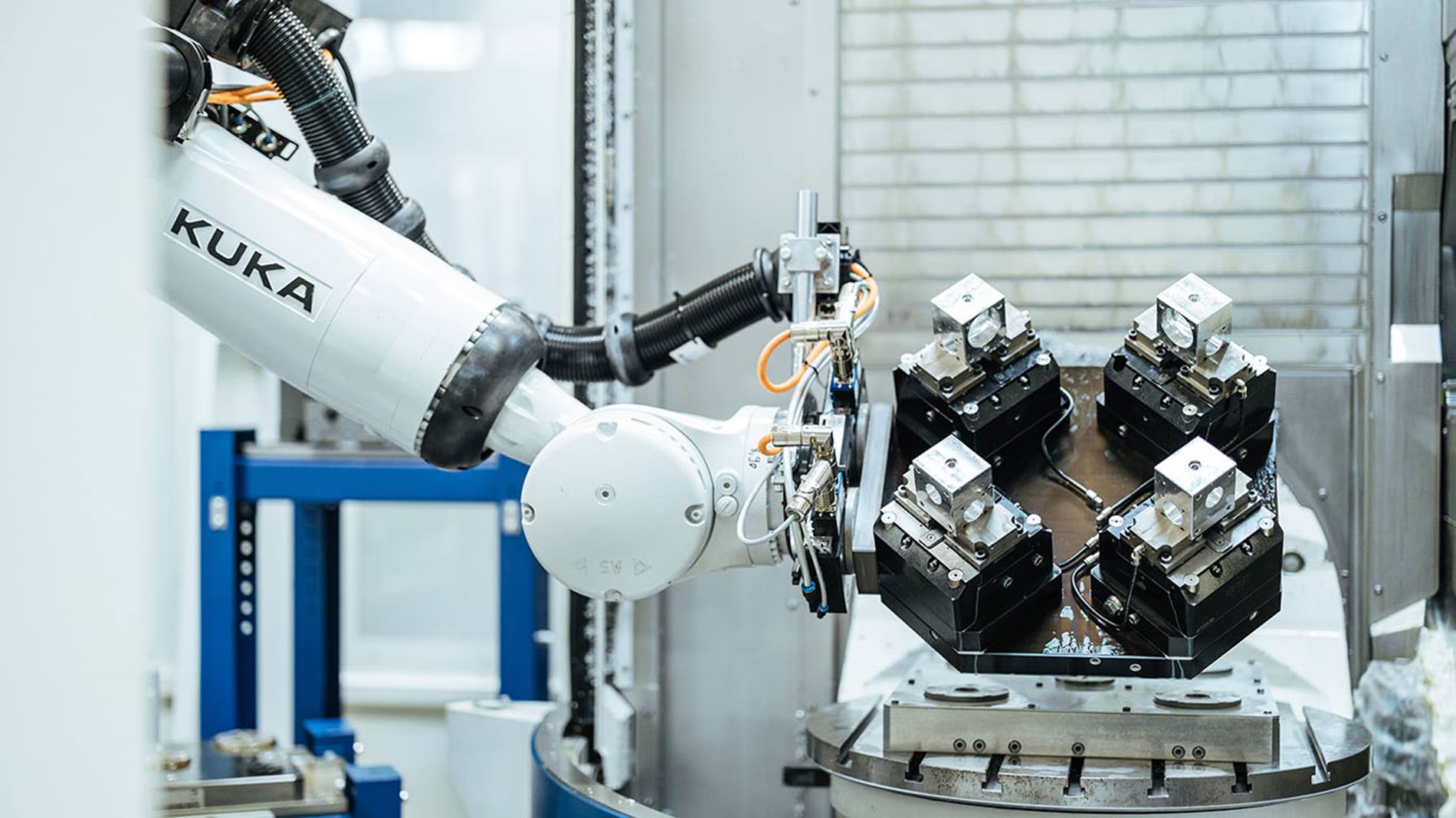

Loading and unloading: Robots work day and night

Do you have expensive machines in your production halls, but cannot work in 3-shift operation due to a lack of manpower? This was the problem faced by the Austrian screw jack manufacturer ZIMM. The solution for the company were the robots KR AGILUS and

KR QUANTEC. They now load a five-axis milling machine, perform automated finishing of the workpieces, and offload the completed screw jack components. Robot and milling machine are perfectly matched to each other. While the milling machine is still working, the KR QUANTEC is already loading another fixture. Once the components – which are also turned automatically – have been finished on both sides, the robot places them on the finishing station in the cell. There the KR AGILUS deburrs and cleans them.

“Among other things, the automation allows us to produce in unmanned shifts at night and on the weekends – which increases our productivity and competitiveness,” explains Hardy Ponudic, Head of Production at ZIMM.Advantage of automation: Productivity, quality and employee satisfaction increase

As the three company examples show, you can greatly increase your productivity by deploying KUKA robots. In addition to the increase in the number of components you can produce, the durability of the robots speaks for their use. Firstly, this pays off financially; secondly, it makes your investment sustainable. Experience also shows that robots do not eliminate jobs, but rather upgrade existing positions and create new jobs in the medium term. In this way, the KUKA robot becomes a part of the workforce, which gains new capacities through automation and can increase productivity. The hours worked by the robot relieve your employees in terms of content and time. This allows skilled workers to concentrate on demanding assignments, while robots take over the monotonous, repetitive tasks. Overall, robot performance reduces the workload on your workforce. Thus, with a good work-life balance, you also have an important argument for employee retention in times of a shortage of skilled workers.