Nomet: Another integration in the KUKA standard

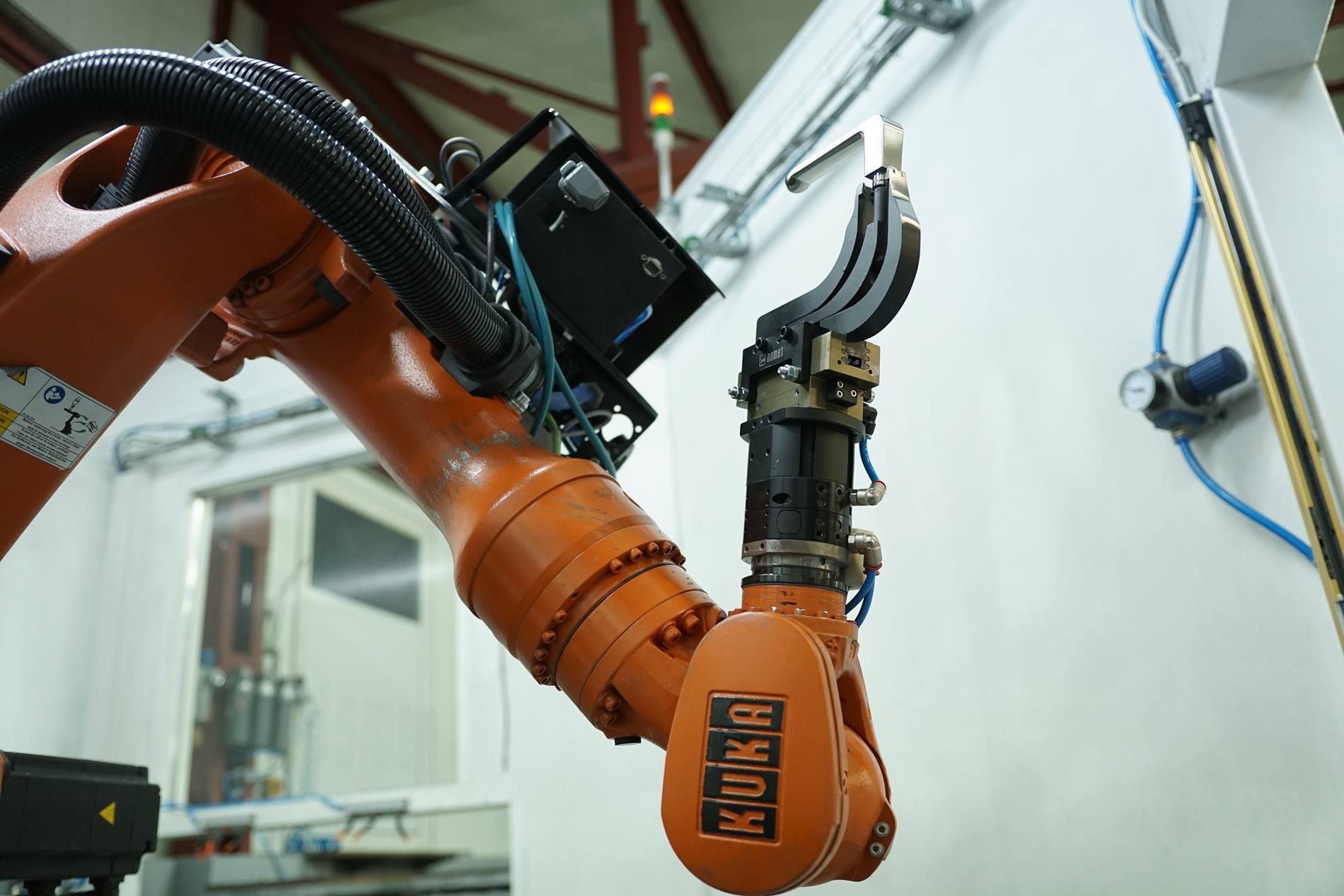

Nomet is one of the largest manufacturers of furniture accessories in Europe. The company's history dates back to the 1980s, but the production in its Torun factory meets the standards of the 21st century. The company has just launched another fully automated production nest, featuring a trusted solution, featuring the KUKA KR 20-3 robot.

When visiting the Nomet factory located in Toruń, it is very easy to see that the company is consistently keeping up with the times. At its headquarters there are already eight automated production nests, five of them include KUKA robots. System integrations, which is the comprehensive preparation of robots for production work, is performed by the company itself. It is carried out by a team of engineers from the Automation and Optimization of Production Department, led by Patryk Czarnecki.

Automation of production translates into increased efficiency and greater repeatability of produced details. We want to carry on going this way. We try to use the newest technologies, of which robots form the basis.

Patryk Czarnecki’s team has changed the way the company works in the Toruń production facility for good. Thanks to his efforts, a series of activities that previously had to be done manually, often requiring employees to make a huge effort, today are almost entirely performed by robots.

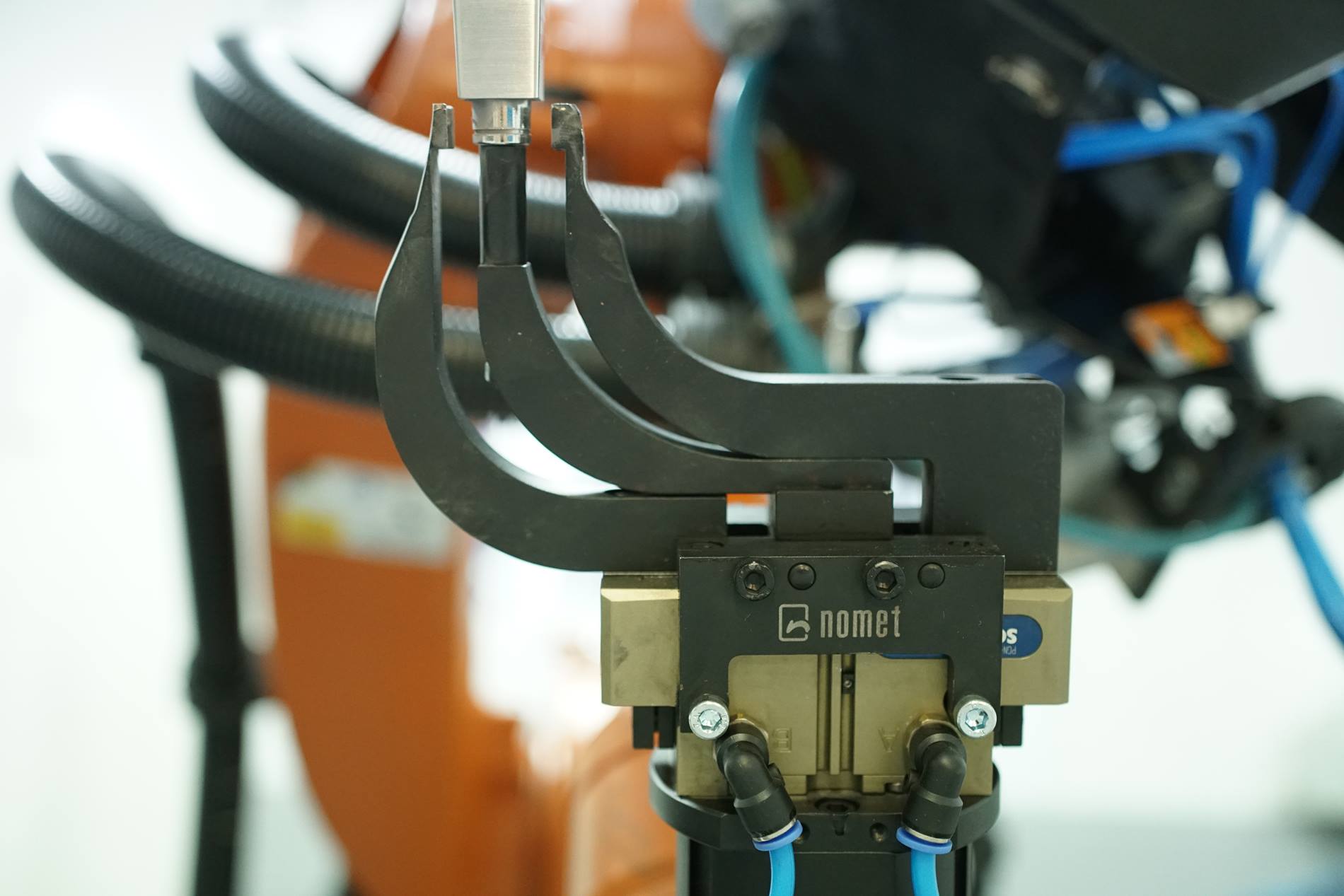

One of the most important changes introduced by the Automation and Optimization of Production Department was the launch of an automated production nest for grinding, polishing and satin finishing of metal elements, based on the KUKA KR 20-3 robot.

"The most important feature of this production nest is that it is ready for immediate tool refitting. We have equipped our production nests with accessories that allow quick change of tools to move to another production process in no time. This is the most universal of our production nests.", says Patryk Czarnecki.

"All three processes - grinding, polishing and satin finishing - are performed by the same robot.", emphasizes the head of the Automation and Optimization of Production Department at Nomet. "We have made a tool set for it ourselves. We also wrote the software that controls the entire nest."

"We assumed that we want to launch a nest that will satin finish the details with little help from a human being. The robot does not feed the detail itself. A human must help with it. This is due to the fact that we produce several hundred different types of products. In fact, it looks like the employee supports the robot, and the robot satin finishes the detail itself.", describes Patryk Czarnecki.

He points out the benefits of such a solution: "The robot satin finishes faster than a human. It is repeatable. The robot always does it the right way. Unfortunately, if someone who doesn’t have an idea about satin finishing, tries to do it, it means that such detail will only be suitable for remelting."

"We begin the robot integration process by analysing the input data. We must know two things: what we need, and what the machine is going to do.", explains Paweł Grzegorzewski, a constructor and a technologist in the Automation and Optimization of Production Department. "Based on these information, we analyse and prepare the concept. My role is to create the entire model. Then, I prepare the construction documentation. Colleagues in the tool shop must produce the tooling, and an appropriate software must be created."

"It can be said that a necessity is the mother of invention.", adds Paweł Grzegorzewski. "We create something that's not on the market. Sometimes the costs of creating something can be greater than the cost of buying a ready solution, but as I said, in this case, there are no ready solutions."

Engineers from the Nomet Automation and Optimization Department have a lot of freedom and it will not change in the near future. At the beginning of 2019, the department intends to launch three new, automated production nests, while further projects are being planned. As announced by the head of the department, the majority will be based on the KUKA standard.

We do not want to introduce many producers for a simple reason: every producer uses different software, robots have different construction and operate in a different way. We want to simplify the way we work. Our employees are used to working with KUKA robots, whether using the control panel or simply cleaning the area around it. For the time being, we are going to use KUKA standard.

Nomet belongs to the leading manufacturers of furniture accessories, such as handles, knobs, legs, as well as construction accessories: door handles for interior and exterior doors. The company offers products from its own production. At present, Nomet employs over 500 experienced and qualified employees. The company's headquarters with its own production halls and warehouse space are located in the industrial district of Toruń.