The KUKA KR Agilus robot at the laboratory of TÜV Rheinland Poland

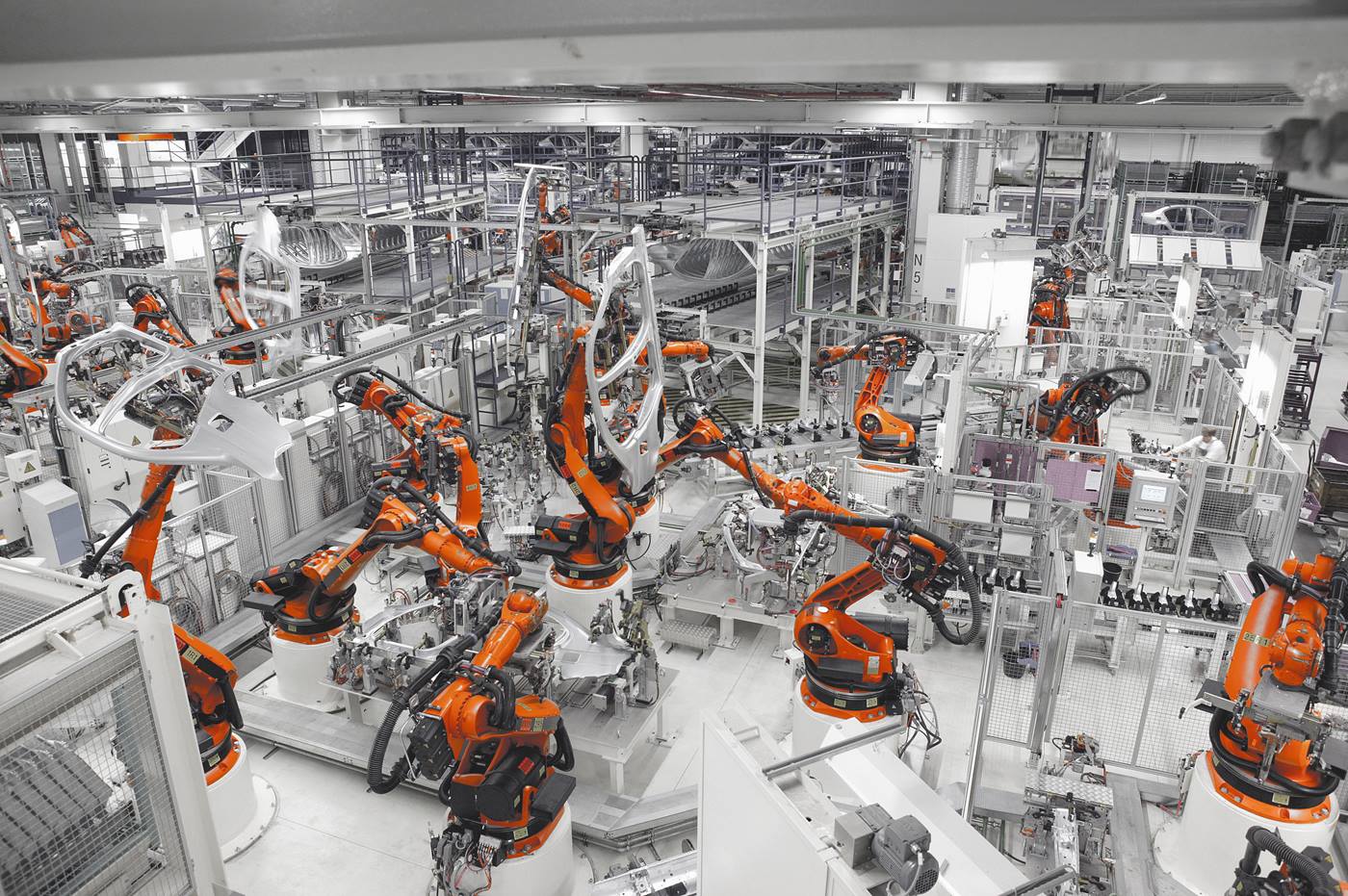

Creative and optimized use of the robot potential is the key to effective automation at the work environment. This goal was achieved at the Polish Branch of the company TÜV Rheinland in Poznań, where each day common use products, such as furniture or household appliances, are tested and certified. The KUKA KR AGILUS robot operates side by side with the personnel of the company.

Product testing methods in TÜV Rheinland

- We carry out safety tests and the so called fitness for use tests, which are carried out for wide range of clients, including networks. The range of products we test is broad. It can be a pan, or a fridge, or automatic lawnmover. We test if, e.g., product life is in fact as declared by the manufacturer - explains Patryk Krakowski, senior mechanical tests specialist at TÜV Rheinland Polska.

Creative and optimized use of KUKA robot

The Poznań team of TÜV Rheinland Polska is supported by the KUKA KR Agilus robot in many tedious testing activities. Its task is mainly the evaluation of durability of tested products. If, for example, durability of the computer keyboard is tested, the robot will carry out cycle test involving applying pressure on the keyboards in compliance with tests programme developed by the expert, reproducing conditions of possible use. Completing such test, specialist of TÜV Rheinland Polska may evaluate if the keyboard in fact meets the product life requirements declared by the manufacturer for the warranty period, or what conditions are required by the certifying body in the event the product is provided for certification. In other cases, the robot may check functionality of the applied system solutions in furniture, e.g. sliding off and in shelves of the chest of drawers numerous times so that the condition of slides can be evaluation.

Robotic device used in the Poznań laboratory of TÜV Rheinland Polska is an example of a creative and optimized use of the robot. Due to a large variety of products tested by the company, the robot must be universal - and it is. It may be freely reprogrammed depending on what precisely has to to be tested, concerning the product properties or safety matters. Integrated grapple adjusted to specific tasks is also universal. Patryk Krakowski is responsible for everything.

Is it possible to learn programming KUKA robot by yourself?

- The company which installed the robot provided a few days training. Unfortunately, I was not employed when the list for the training was drawn up. Those who took part in the training were later on assigned to other tasks, which were not necessarily closely connected with using the robot. It was not the same in my case. I was able to freely learn how to operate it, using the potential I discovered to perform new projects. Thus, I combined the practical with pleasure - recalls Patryk Krakowski.

- I learned everything by myself. I had to discover everything by myself, but I have to say that basics of robot programming are very easy. Basic knowledge on programming is enough. KUKA uses language which can be easily learned.

Advantages of KUKA robots

Patryk Krakowski specifies few key benefits he finds in using the robot. One of the most important is reliability. Contrary to human, the robot does not get tired, does not get sick, and can work without breaks, also at night, which is especially important considering specific nature of business activity of TÜV Rheinland Polska. It is obviously not everything. Properly programmed, the robot can test few products at the same time. Repeatability of robot’s movement allows for obtaining maximally reliable tests. Its operation is facilitated by the act that the robot is mobile. It is because the robot was installed on a dedicated platform equipped in a wheelset. Thus, if needed, it can work at the workstation where it is needed. Everything depends on the current needs of the company’s employees.

Versatility of testing application

The manner in which TÜV Rheinland Polska uses the potential of this popular KUKA KR Agilus robot shows how many possibilities we have choosing robotic solutions at the work environment. In the case of TÜV Rheinland Polska the robot is invaluable assistance for the experienced team of specialists taking over their tasks which could be tedious, repetitious and very tiring. Thanks to universal grapple, there are no challenges that cannot be done, regardless of what kind of product is tested.

Further development of TÜV Rheinland

TÜV Rheinland Polska is a leading company in the sector of certification and testing services in Poland. The company belongs to an international concern TÜV Rheinland Group, which is a leading supplier of this type of services around the world. Based on many years of experience of the TÜV Rheinland Group, the Polish branch offers its services to enterprises from various sectors of industry and trade.