Four phases of Service Life Cycle Management

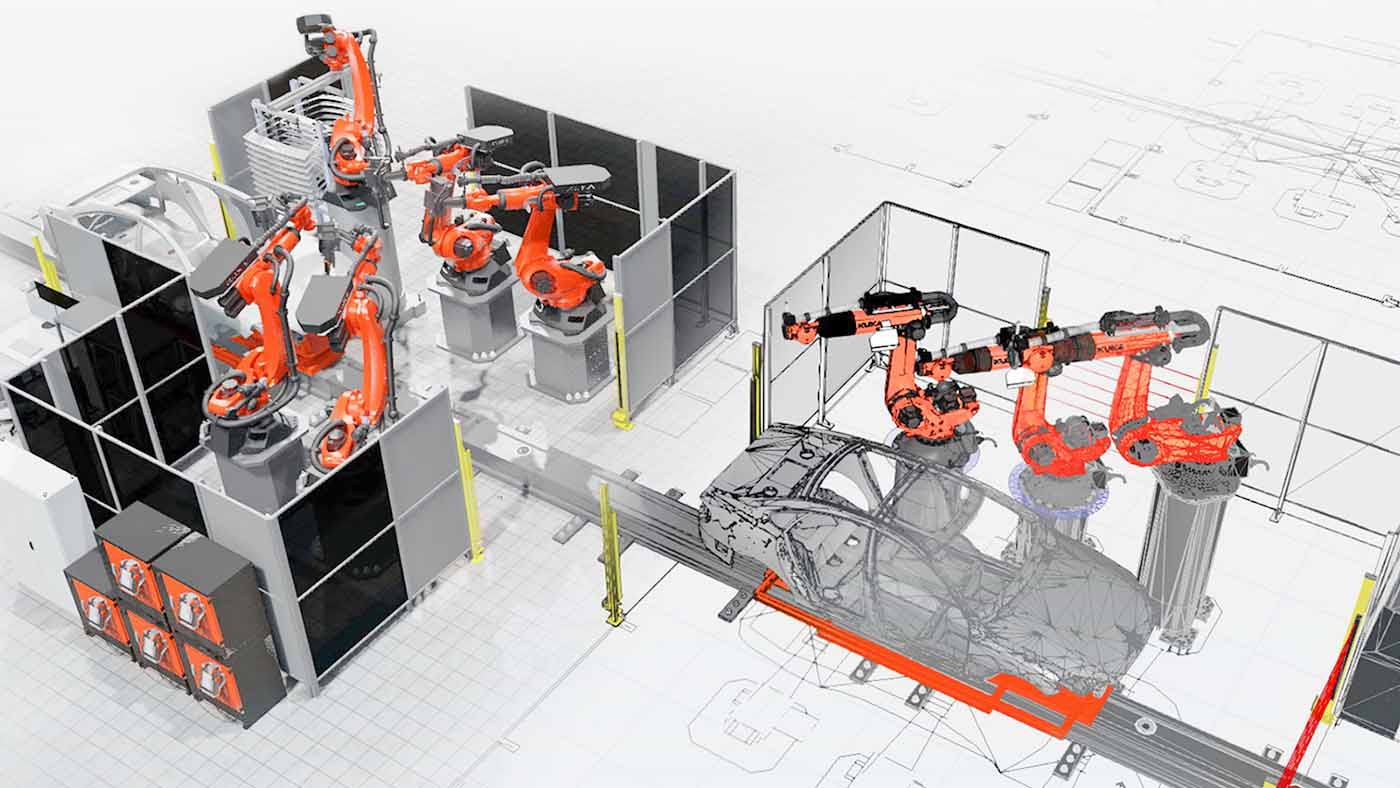

Planning and simulation of robot systems

The foundations for successful automation are laid by selecting the ideal type of robot and technologies to be used. We will work with you to plan the appropriate solution for your task, using simulations, feasibility studies and test set-ups. This reduces planning risks and prevents unnecessary follow-up costs from the outset.

You also benefit from our wide range of courses. The KUKA College will support your employees with a clever combination of digital learning methods and practice-oriented classroom training.

Programming and start-up

We use our expertise to ensure that the commissioning and start-up phase of your automation solution runs smoothly and efficiently in the shortest possible time. In doing so, our technicians take charge of programming, developing smart application solutions and ensuring that the robots are installed flawlessly.

We can handle any project, from minor program changes to the implementation of a complete robot cell. You can always rely on the highest quality standards from our service management team.

System maintenance and repair

The availability, performance and quality of automation systems are decisive features for successful production systems. For that reason, we offer you customized services and preventive maintenance to ensure the continuous operation of your robotic system. These include a guaranteed supply of spare parts, inspections and expert repair services as well as professional performance checks.

Robot service management is carried out according to the most stringent standards in all areas. This is how we maximize system availability and guarantee that your production output remains consistently high.

The extended life cycle of robots

Be it upgrades or system overhauls – we guarantee that your automated robot solutions can be used sustainably over the long term. Our experts take various steps to optimize your systems based on the operational parameters and individual requirements.

In the final phase of the service life cycle, these range from targeted upgrades to comprehensive repairs or even replacing your robot system entirely. This enables us to grant your investment a reliable second life cycle.