Augmented reality in education and training at KUKA - Learn to weld virtually

Welding is as much a part of sound technical training as learning to write the alphabet. Trainees at KUKA learn this craft as early as their first year of training. This now includes welding in the virtual world in a four-week advanced training course.

Innovative teaching methods such as the use of digital tools characterize training at KUKA. For some time now, trainees have been benefiting from another application: the virtual welder. A mixture of modern hardware and special software enables trainees to learn welding using augmented reality.

The simulator is by no means a substitute for "real" welding. That is why the trainees also start with "real" welding in their course. Afterwards, the knowledge and skills are deepened with the help of the virtual welding device.

The big advantage is that virtual welding does not consume any materials. It is also safe and welding results can be analyzed very precisely.

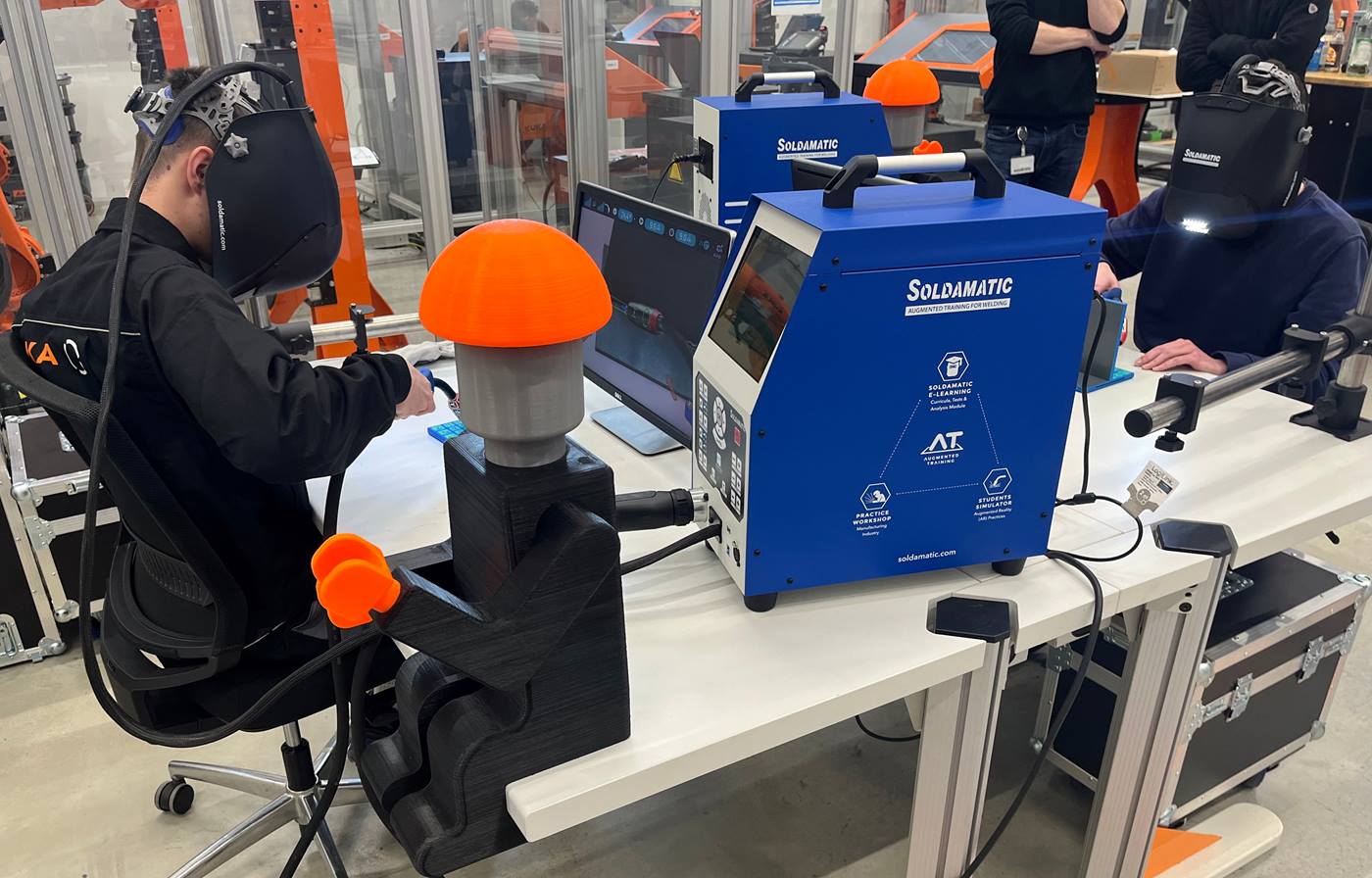

The user welds simultaneously in the digital and real world

The welder consists of a computer with an integrated screen and numerous function keys, as well as the welding mask, in which cameras and a screen are built in.

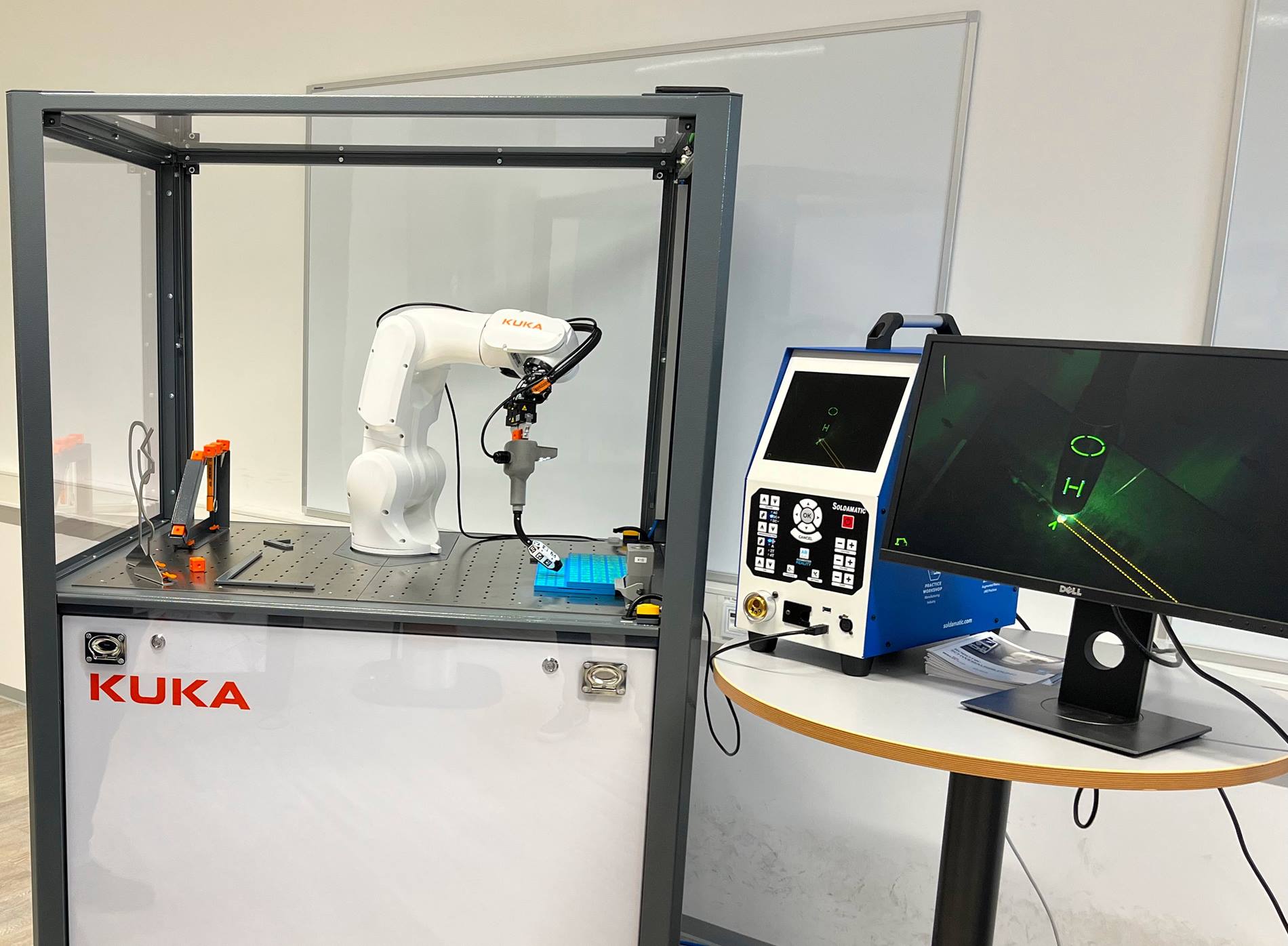

The KUKA KR4 AGILUS sits in a KUKA ready2_educate cell. The special feature is that the welding torch attached to the robot is used to simulate welding on various components mounted on the floor of the cell. The welding machine's computer and a control unit for the robot are also part of the cell.

Thanks to these innovative tools, young talents can develop their welding skills - straightforwardly and sustainably.