Wanted: Flexible and mobile robot applications

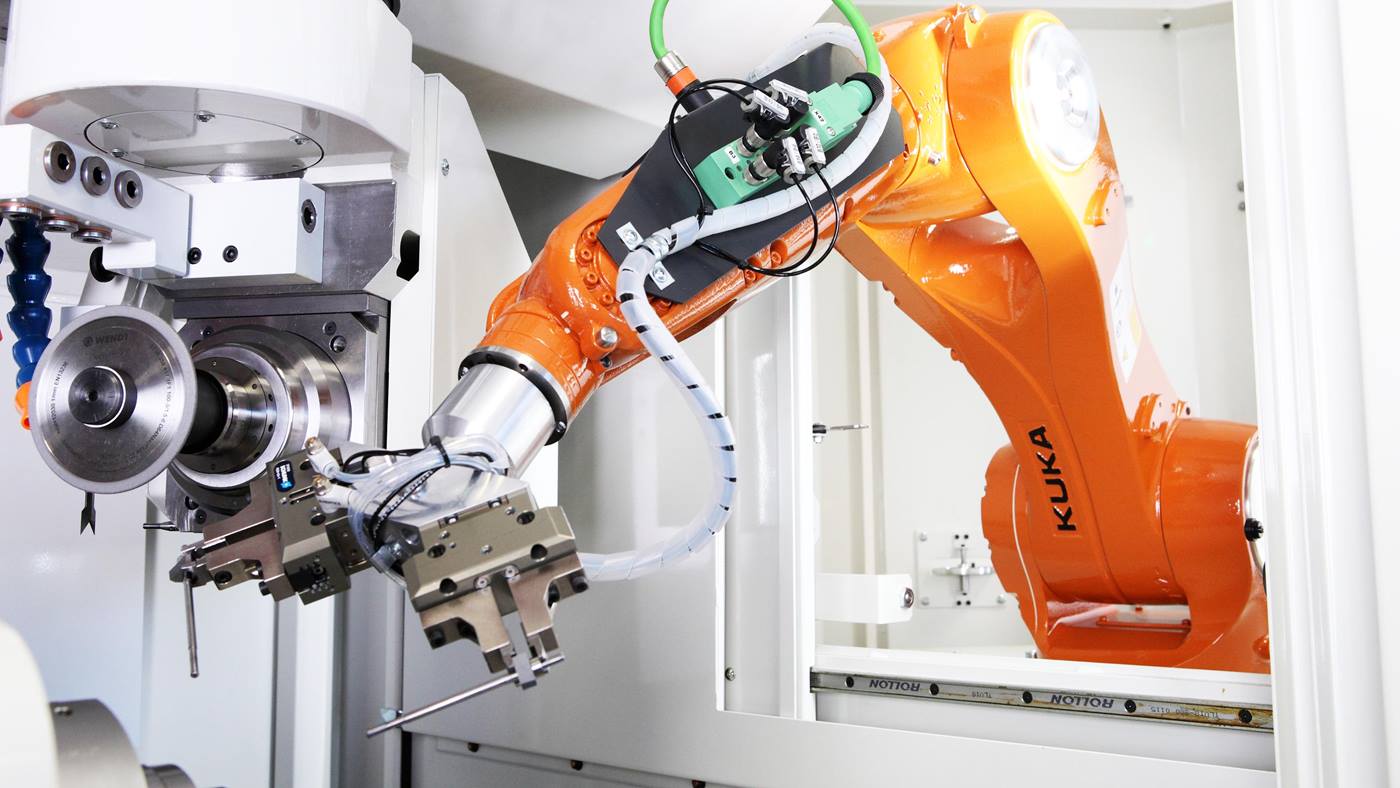

LMZ specializes in the construction of special-purpose machines and machining technology. LMZ supports its customers from the automotive, plastics and hygiene industries with robot-based automation. “Robotics is a topic that preoccupies many small and medium-sized enterprises. They would like to automate larger parts of their production using robots. Up to now, however, corresponding solutions have not been flexible and versatile enough,” says Dennis Lenkering, Managing Director of LMZ. This is why Lenkering and his team developed a cost-effective, versatile mobile robot application.