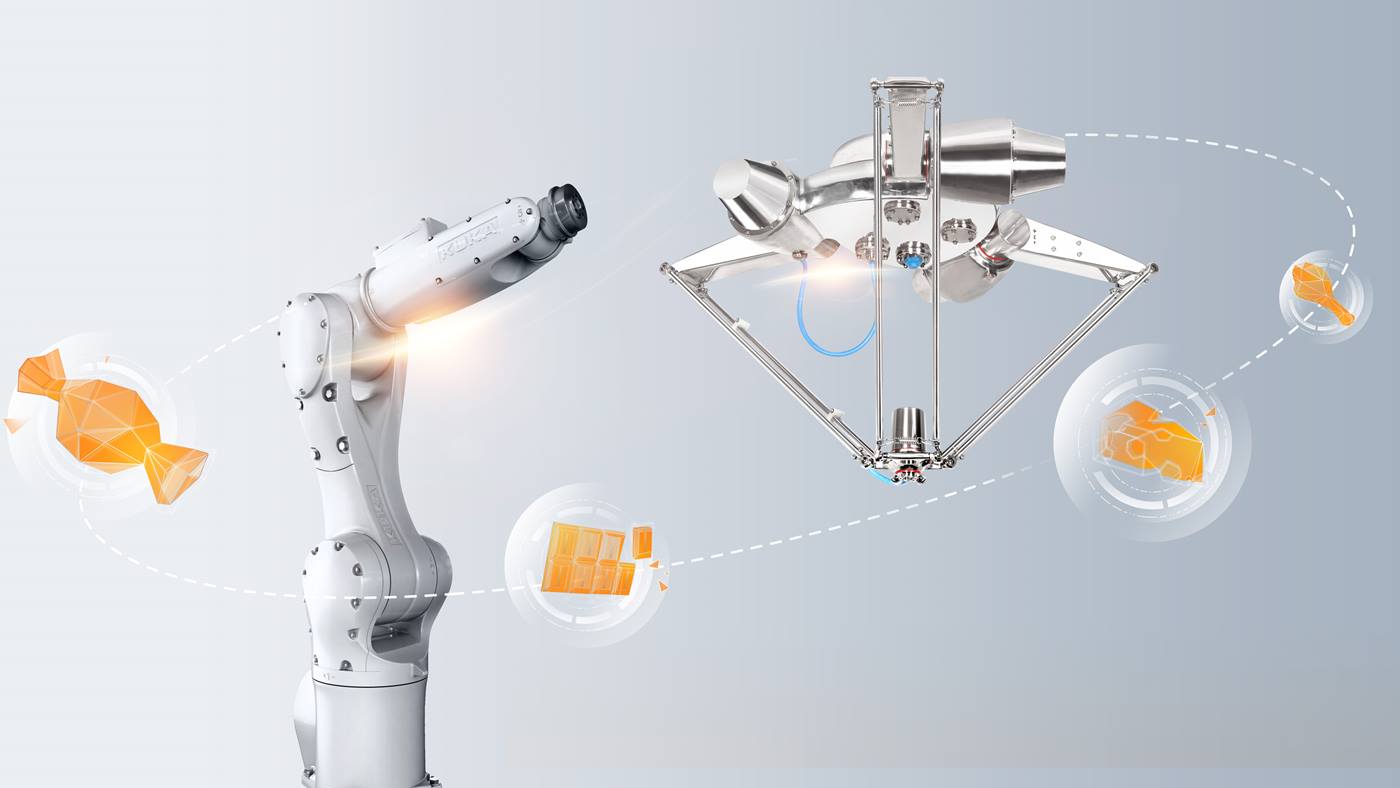

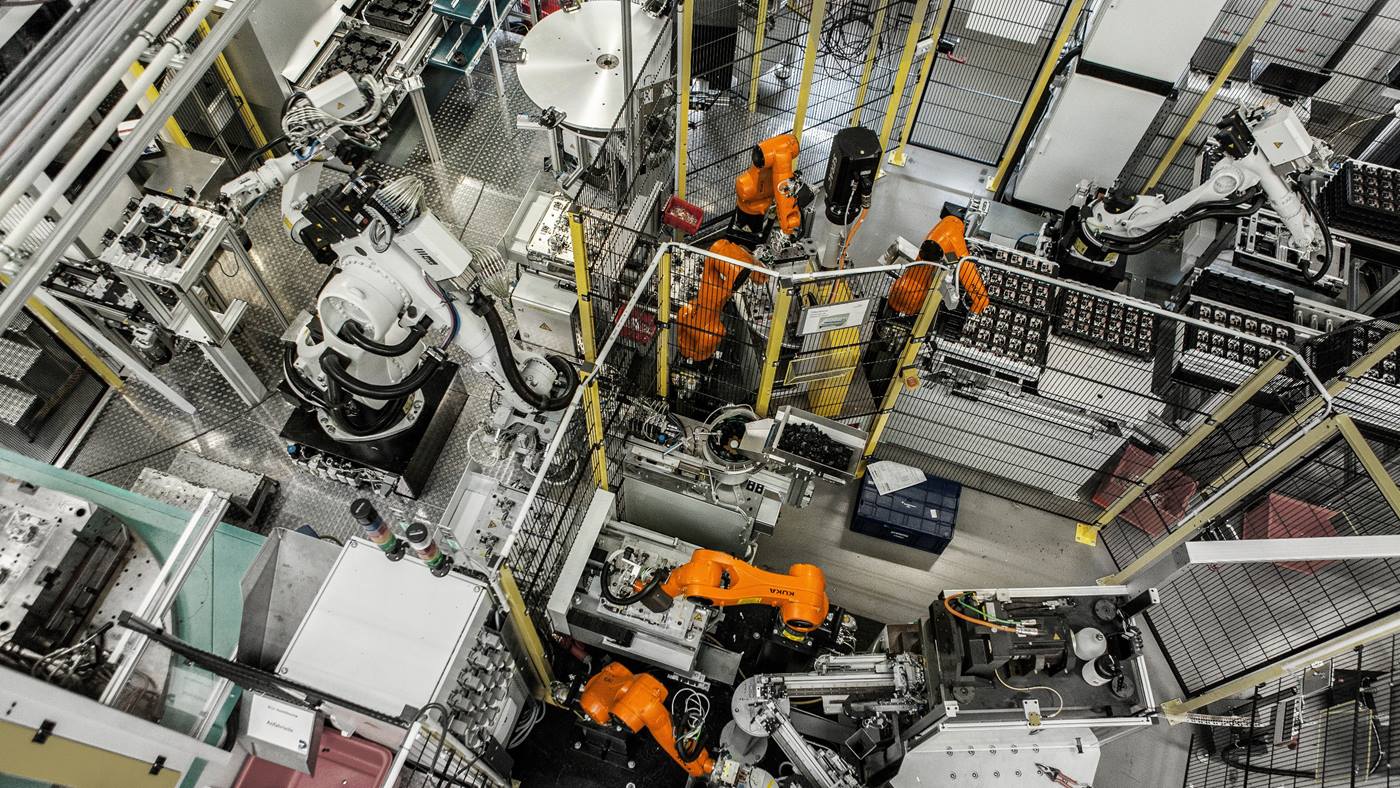

Pick and place

We can help you integrate an automated pick-and-place system that is perfectly suited to your needs. Whether loading and unloading machines, sorting, packing or handling food: our pick-and-place robots set the pace.

Precision on the move

At KUKA, decades of know-how meet software, robots and cells capable of rapidly automating the entire process chain. By using pick-and-place robots along conveyor belts, you save valuable working time that your employees can use for value-added activities. Together we can find your ideal pick-and-place system – tailored to your production environment, tasks and products to be handled.

Pick and place & machine loading and unloading

The loading and unloading of machine tools, process and testing machines is one of the most common tasks in the field of pick & place. The industrial robots load the individual blanks and unload the finished parts. There is a great variety of applications:

- Gluing machines for smartphone production

- In-circuit testers in electronics manufacturing

- Battery process machines

- CNC machines

- Injection molding machines

Pick and place & order picking

The requirements in the e-commerce, pharmaceutical and retail sectors are becoming increasingly demanding. Robot-based item picking with ItemPiQ from Swisslog helps to reduce operating costs and improve work efficiency in small parts warehouses. Depending on size, weight, goods-to-robot system and storage method, ItemPiQ is capable of picking up to 1,000 items per hour. The advantages:

- Seamless integration of software solutions

- Wide product variety

- Easy to operate

Pick and place & measuring and testing

Pick and place & handling

Picking and placing goods requires high precision. This is especially true for short-cycle production environments. Robots are the optimal choice here: they provide high-speed assistance around the clock. This includes blood samples (see video) as well as cheese, fruit and vegetables. Other examples include:

- Automation of lines for printed circuit boards (PCBs)

- Glass handling in smartphone manufacturing

- Handling of wafer boxes

- Handling of small parts

- Handling of battery cells

Pick and place & packing

Pick-and-place robots are also an asset in the process area of packing. Together with the KUKA.PickControl software package, you can easily coordinate and control multiple robots, for example to increase productivity during packaging. Possible applications include:

- Packaging of 3C devices (for example, smartphones, laptops, tablets, office equipment, etc.)

- Packaging of foodstuffs

- Attachment of protective pads to the top of televisions before packaging

Pick and place & palletizing

There are also pick-and-place tasks in the field of palletizing. For this purpose, KUKA offers customized solutions for palletizing applications of all types and complexity. The palletizing robots with payloads of up to 1,300 kilograms and the KUKA.PalletTech palletizing software make it possible to improve performance quickly and easily, for example in these pick-and-place tasks:

- Mono-palletizing

- Cold storage palletizing

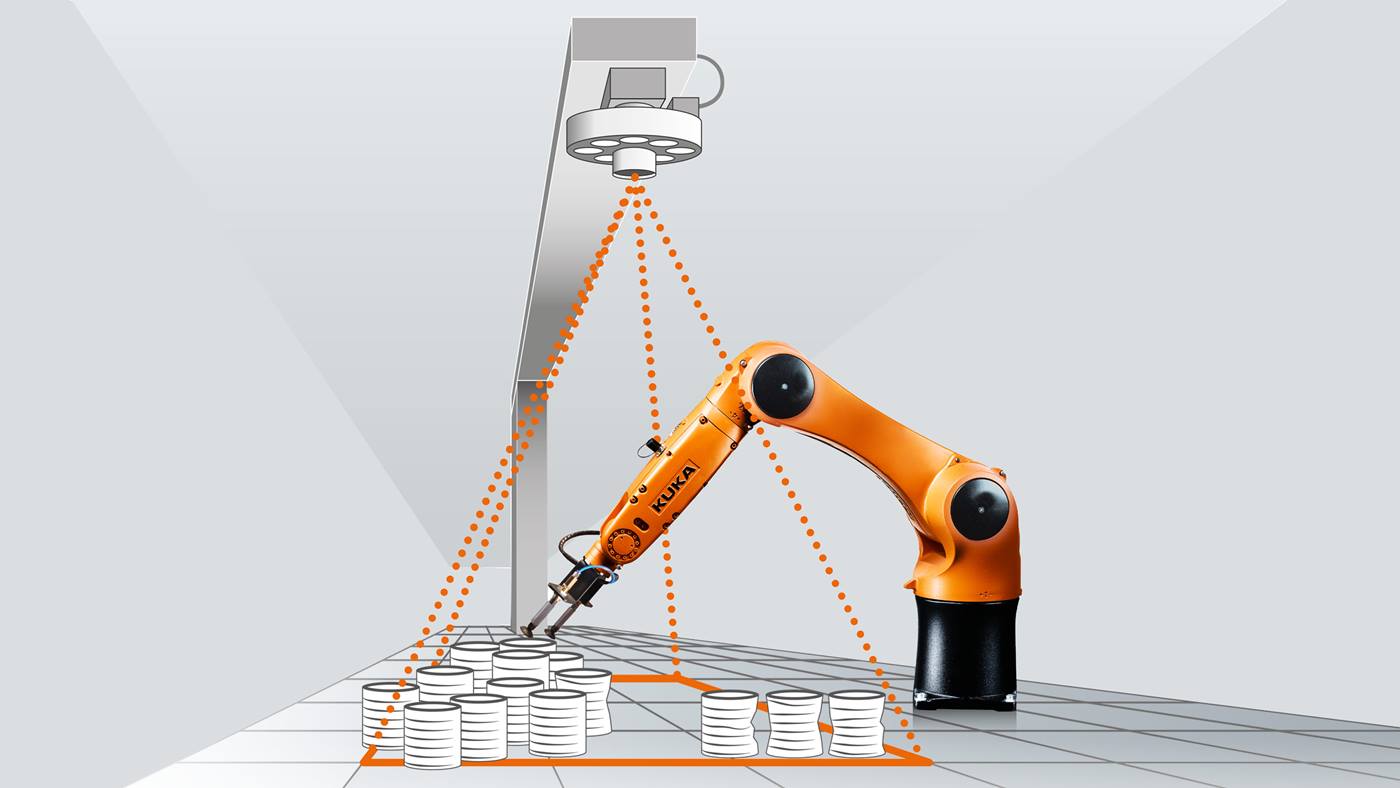

Pick and place & bin picking/sorting

KUKA industrial robots reliably detect every component, even in the greatest chaos: so-called bin picking involves picking unsorted parts from bins and other containers. The ultimate pick & place challenge can be intelligently automated with the combination of robot arm, gripper, software and 3D sensor for image processing.

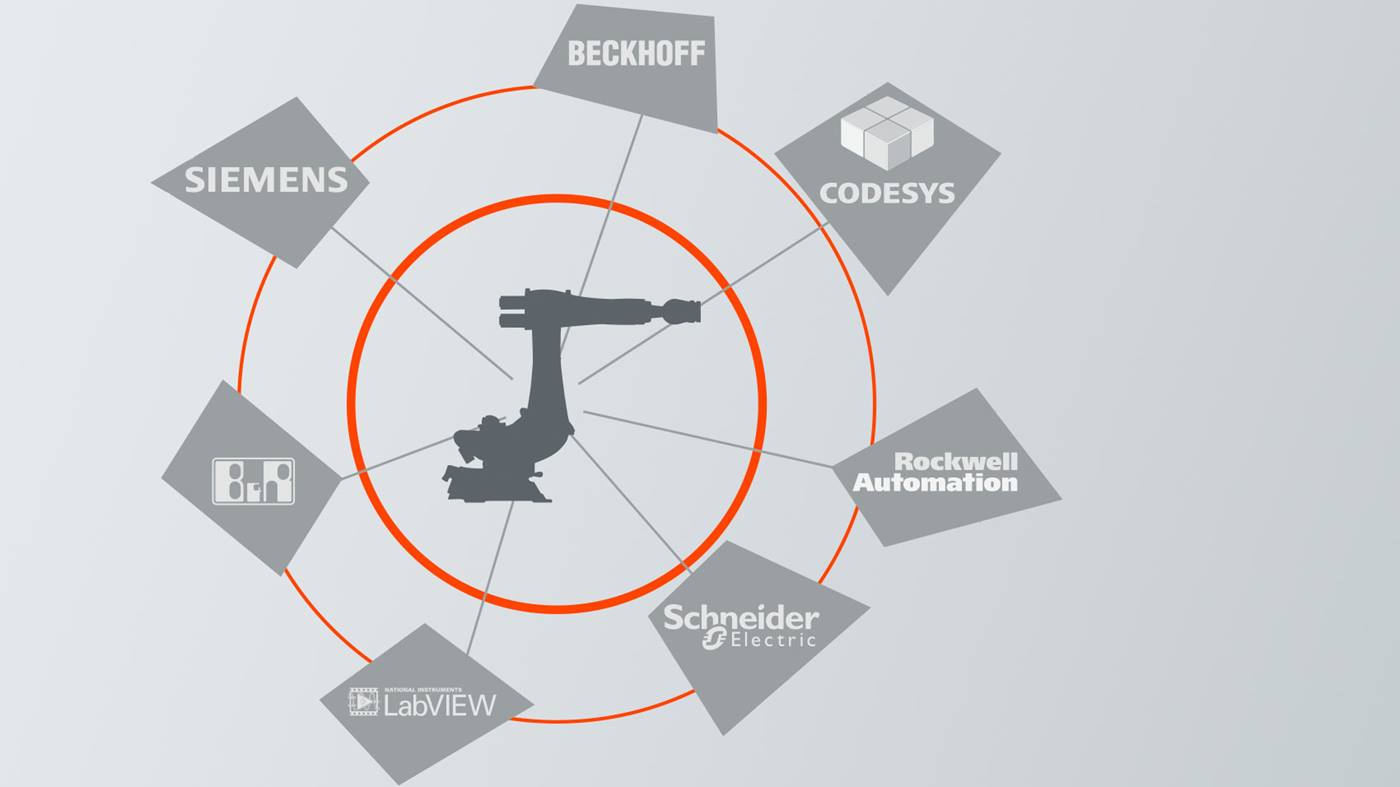

KUKA pick and place: the information advantage

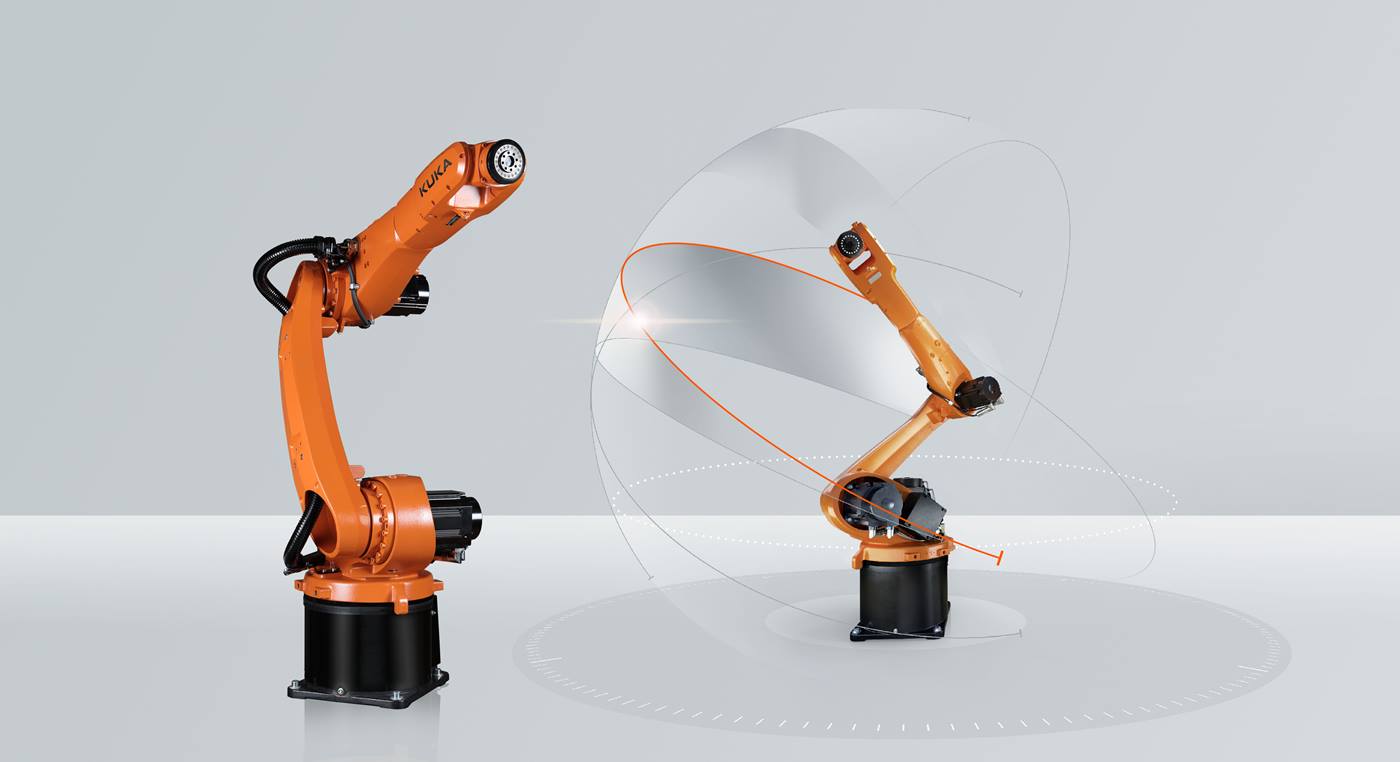

KUKA know-how for your needs: technologies at a glance

Our automation knowledge is as extensive as the variety of pick-and-place applications. Here you can see at a glance the tasks and process technologies for which we can provide you with technical support:

Available at all times: your access to product information and digital services for pick and place

In the my.KUKA digital customer portal, you can check product data and product availability at any time, purchase hardware (including spare parts) and software products directly online, manage licenses and support requests, and much more.