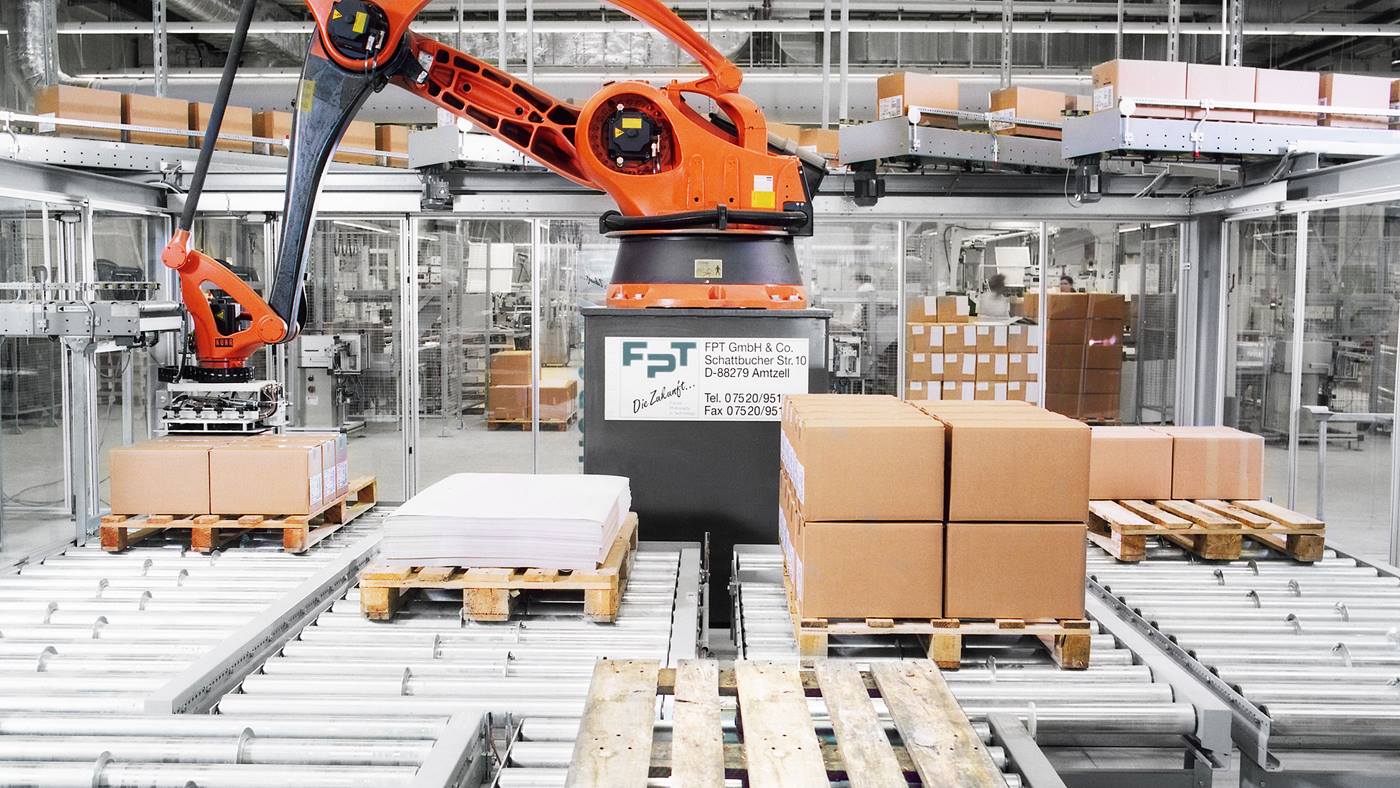

Innovative palletizing software for quick and flexible palletizing of unmixed articles

With KUKA.PalletTech, you can configure your palletizing application even without comprehensive programming knowledge. By automatically generating the robot programs, the technology package enables extremely quick start-up of complete palletizing applications.

Thanks to customized adaptations, the software can be specially tailored to your requirements and integrated into your existing production.